Landmark Transplant Turns 3D Bioprinting on Its Ear

A reconstructed ear made of living cells could herald a new era of 3D-printed organs

More than a quarter-century after scientists first grew a humanlike ear on the back of a mouse, surgeons in San Antonio have successfully used a 3D printer to reconstruct an outer ear made of living cells for a young woman with a congenital ear deformity—no creepy-looking mice required.

Researchers hailed the pioneering transplant as a major advance for tissue engineering and regenerative medicine.

Conventional 3D printers that extrude biocompatible plastics are regularly used to create medical implants such as airway splints, heart valves, and spinal discs. But the San Antonio operation—announced last week as part of a clinical trial sponsored by 3DBio Therapeutics, a Cornell University spinoff—appears to be the first to pattern a 3D-printed transplant out of living tissues.

Yet, it is one thing to bioprint an outer ear so that the external appendage will largely serve a cosmetic purpose. It is quite another to fashion complex organ systems that must play essential metabolic and sensory roles.

“This bioprinted ear auricle is an important milestone in the industry, but there is still work to be done to bioprint replacement tissues or organs that need to perform complex biological functions,” says Sam Wadsworth, cofounder and chief scientific officer of Aspect Biosystems, a Canadian company working on bioprinted tissue therapeutics.

Nonetheless, the fact that the ear transplant appears to be safe, with favorable aesthetic outcomes, at least initially, should pave the way for future clinical applications of 3D bioprinting. So says Jennifer Lewis, a materials scientist at Harvard University who was not involved in the research.

“It’s the right place to start to derisk the technology,” she says.

The recipient of the bioprinted ear, a 20-year-old woman from Mexico, was born with microtia, a rare birth defect that causes the ear to develop with a small and misshapen outer structure.

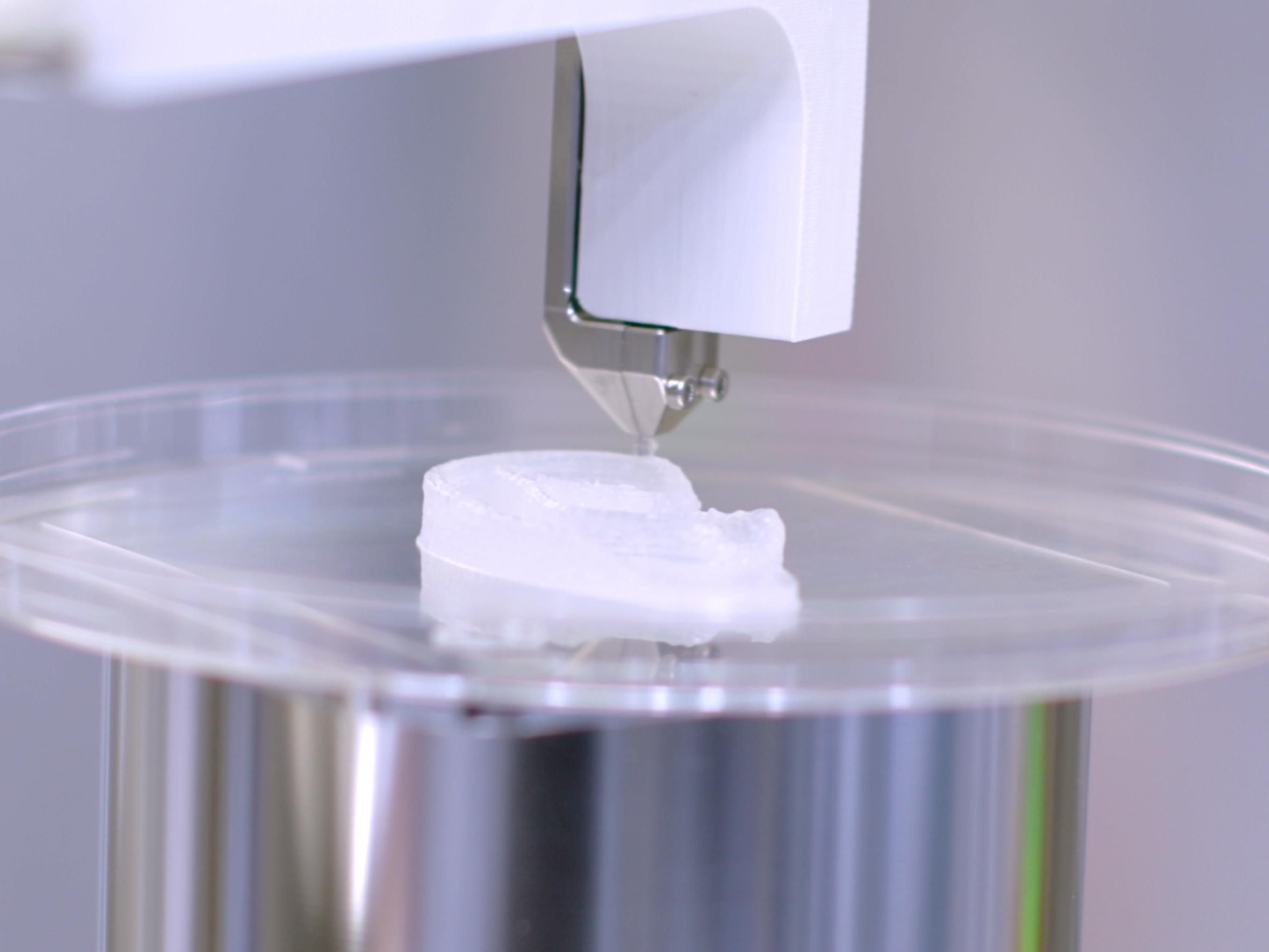

Doctors took a nib of tissue from her deformed right ear, plus a 3D scan of her healthy left ear. Scientists at 3DBio HQ in Long Island City, N.Y., then extracted cartilage-forming cells from her biopsy, grew huge numbers of those cells in the lab, and mixed the cells with a collagen-based “bioink” for loading into a proprietary printer.

Using the good ear as a guide, the computer-controlled printer deposited the material in thin layers to create a personalized, shape-matched prosthetic that was then ready for transplantation, with the aid of a temporary biodegradable shell.

Conventional microtia reconstruction typically involves harvesting and carving rib cartilage in a procedure that requires multiple surgeries. In recent years, surgeons in China and Israel have used less-invasive 3D-printing protocols to create synthetic ear scaffolds that then be seeded with cartilage cells or covered in grafted skin.

The 3DBio method, however, is to first to take advantage of a live-cell printing technique.

The company’s microtia trial is scheduled to enroll another 10 individuals at sites in San Antonio and Los Angeles. 3DBio next hopes to deploy its cartilage-printing technology to correct nasal and spinal defects.

Other companies in the field are mostly offering their bioprinting services as research tools—for disease modeling, drug testing, and the like.

Organovo, for example, sells a 3D-bioprinted human liver tissue product designed for evaluating the toxicity of experimental drug compounds. In the mid-2010s, the company tried to develop a liver therapeutic, bioprinted with multiple cell types in a precise configuration.

Its scientists even reported some success at treating assorted liver diseases in mice. But the benefit proved marginal. And three years ago, Organovo abandoned the strategy, opting to focus on its drug-screening platform instead.

Other firms have similarly pivoted away from 3D bioprinting in favor of easier-to-commercialize medicines, while the technology has found a new home in the burgeoning cultivated meat industry. But a few startups are continuing to prioritize the high-risk, high-reward proposition of biofabricated tissue therapeutics.

Among them is Precise Bio, which is hoping its 3D-printed corneas can help treat blindness.

Meanwhile, Trestle Biotherapeutics is using 3D bioprinting and stem-cell biology methods developed by Lewis, the Harvard scientist, to engineer kidney tissue for renal repair.

And United Therapeutics is focused on making a limitless supply of 3D-printed lungs for transplantation. On 6 June, the company reported that its technology had achieved gas exchange in animal models.

Complete organs like the ones United is developing could one day obviate the need for transplants from living or deceased donors —and, as Lewis points out, “ultimately that is the goal” of the field.

But there’s a long way to go from reconstructed ears to, say, a working kidney. That’s why most companies plan to advance 3D-bioprinted patches or small implants first.

Aspect, for example, uses microfluidic printheads to create layers of cell-laden fibers (complete with a protective material that shields the bioengineered tissues from immune attack); that is a necessary step for addressing an autoimmune disorder such as type 1 diabetes.

Over the weekend, the company announced that its 3D-printed tissue, created with a mix of pancreatic islet cells and proprietary biomaterials, helped to correct diabetes in rat models. Bioprinted liver therapeutics are under development as well.

“Printing an organ and all of its relevant architecture and function is really difficult and not always necessary,” says Aspect cofounder Wadsworth. “And so, we’re not trying to rebuild a whole pancreas; we’re not trying to rebuild a whole liver. We’re rationally designing bioprinted therapeutic tissues that replace functions lost due to disease.”

- Students Win $10,000 Grant to Build 3D-Printed Prosthetics for Dogs ... ›

- 3D Bioprinter Prints Tissue in Situ - IEEE Spectrum ›

- Origami Inspires Sensor Implanting Method for Bio-Printing - IEEE Spectrum ›

Elie Dolgin is a science writer specializing in biomedical research and drug discovery. After a PhD spent studying the population genetics of nematodes, he swapped worms for words—entering journalism as an editor at The Scientist, Nature Medicine, and STAT. Now a freelancer, Elie is a frequent contributor to New Scientist, Nature, IEEE Spectrum, and more.