THE INSTITUTEA German shepherd that lost part of his leg will soon have a new motorized prosthesis, thanks to the Iota Delta chapter of IEEE Eta Kappa Nu (IEEE-HKN) and volunteers at the Stevens Institute of Technology, in Hoboken, N.J.

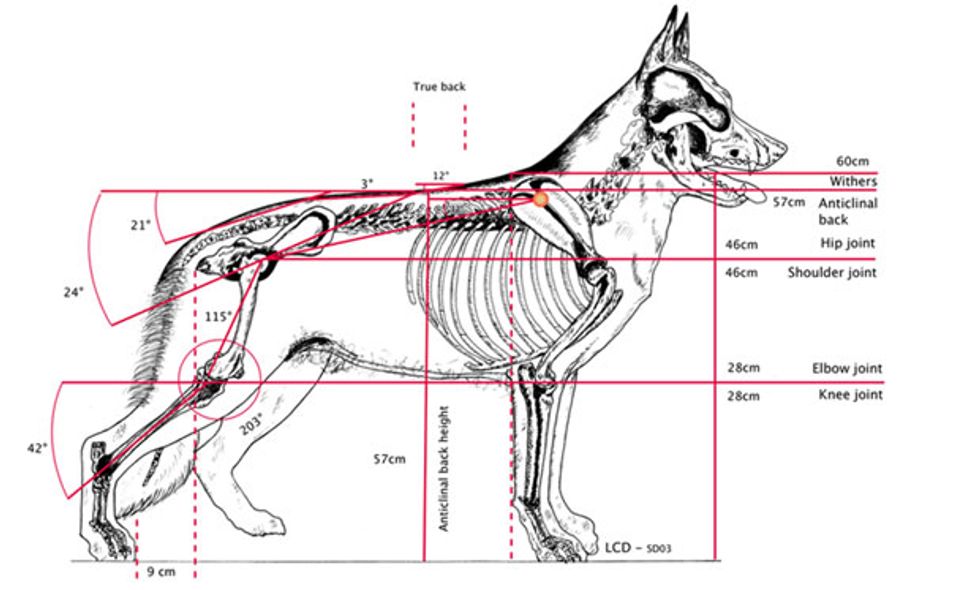

Buddy was abandoned last year outside of Animal Care Centers of NYC in Brooklyn. Shelter workers believe his left hind leg was ensnared in a wire or wrapped in a rubber band and became infected, causing 1-year-old Buddy to gnaw off his foot and part of his ankle. To save the dog’s life, a veterinary team amputated the bottom part of the leg and attached a prosthesis. The prosthesis gives Buddy a limited range of motion, however. The veterinary team says they expect the limitation would ultimately result in hip dysplasia, which likely would limit the dog’s use of his hind legs.

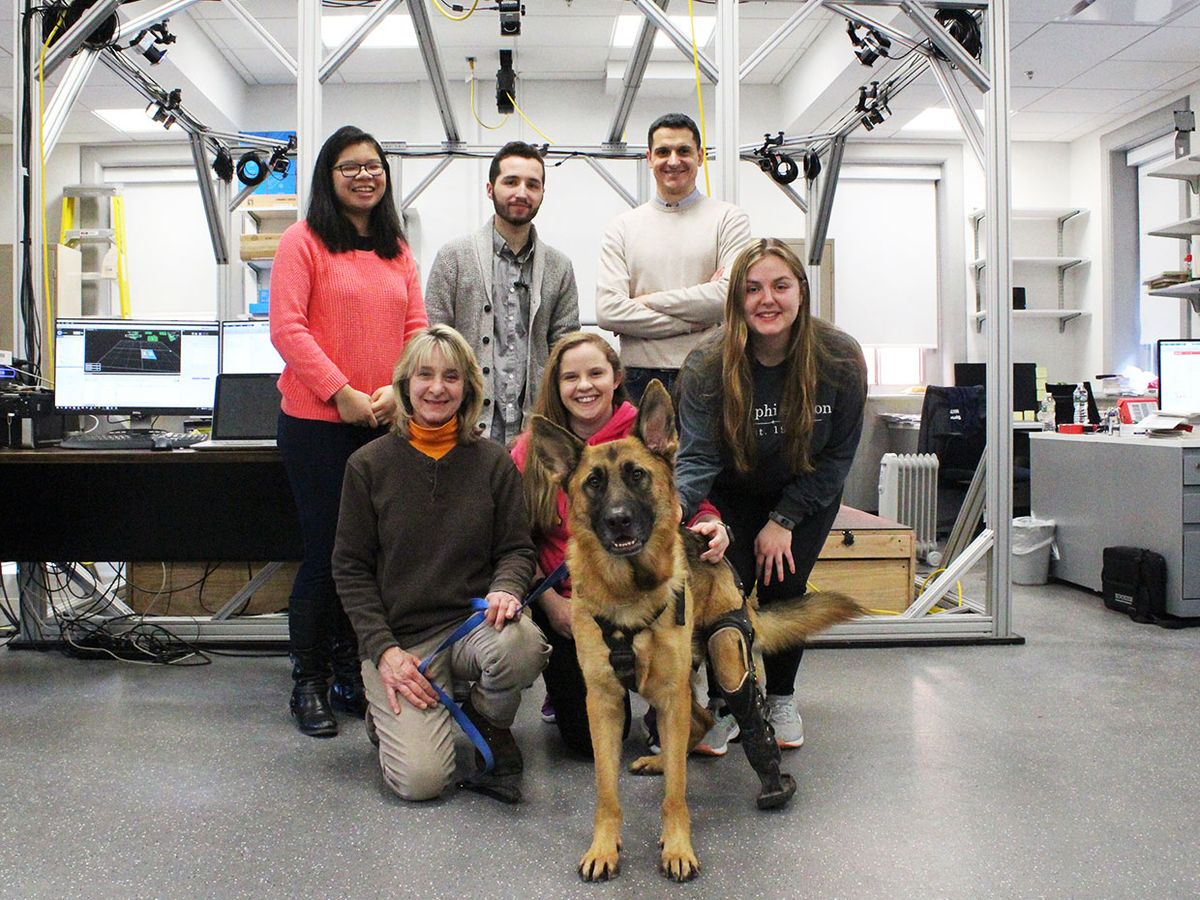

After watching a TV news story about Buddy, the Stevens team—consisting of graduate students, undergrads, and professors—decided to take action. They applied for a grant and received US $10,000 from EPICS in IEEE, a program designed to empower high school and college students to use technical solutions to aid communities. With the grant money, the team plans to build a motorized transtibial—below-the-knee—prosthesis using 3D modeling and printing.

IEEE Member Damiano Zanotto, an assistant professor of mechanical engineering at Stevens, is the team’s lead. He says such a prosthesis has never been created for a dog due to cost and weight limitations. Recent developments in more compact and lightweight components—such as sensors, controllers, and battery packs—now make it possible, he says.

Potential Scalability

The team is working to finish the prototype of the prosthesis and ultimately plans to build an adaptive, rugged model equipped with a motor, a microcontroller, a linear potentiometer, and an inertial measurement unit. The potentiometer can help to minimize Buddy’s energy exertion, while the inertial measurement unit reports on his body’s specific force and orientation.

Zanotto says one of the highlights for the team has been getting to meet Buddy. In addition to some playtime, the team was able to measure the dog’s gait and collect other data in order to ensure his movement with the prosthetic device is as natural as possible, reducing the chances of a future hip injury.

Advancements in rapid prototyping technologies, especially in 3D scanners and printers, allows for protheses to be more easily customized and altered, Zanotto says.

The team says the prosthesis, which it expects to complete by the end of the year, eventually could be modified to fit not only German shepherds like Buddy, but also a variety of dogs.

EPICS in IEEE is funded by donations to the IEEE Foundation.

Currenti, an IEEE Educational Activities intern, is pursuing a master’s degree in voice and opera at the University of Maryland in College Park.