Organic solar cells have remained a bit of a commercial disappointment. There are a number of reasons for this. Some point to the use of the expensive indium-tin-oxide (ITO) in the electrodes. Still others believe the use of fullerenes as electron acceptors has kept organic solar cells from achieving wider commercial adoption.

Researchers at Princeton University, led by electrical engineer Stephen Chou, have developed a nanostructure that promises an economical way to nearly triple the efficiency of organic solar cells and garner them a stronger foothold in the commercial market.

The Princeton research (“Ultrathin, high-efficiency, broad-band, omni-acceptance, organic solar cells enhanced by plasmonic cavity with subwavelength hole array”), which was published in the journal Optics Express, claims to have developed a nansostructured sandwich of metal and plastic that increases the efficiency of the solar cells by 175 percent. The nanostructure manages this feat by reducing the amount of light reflecting off the cell and increasing the amount of light captured by it.

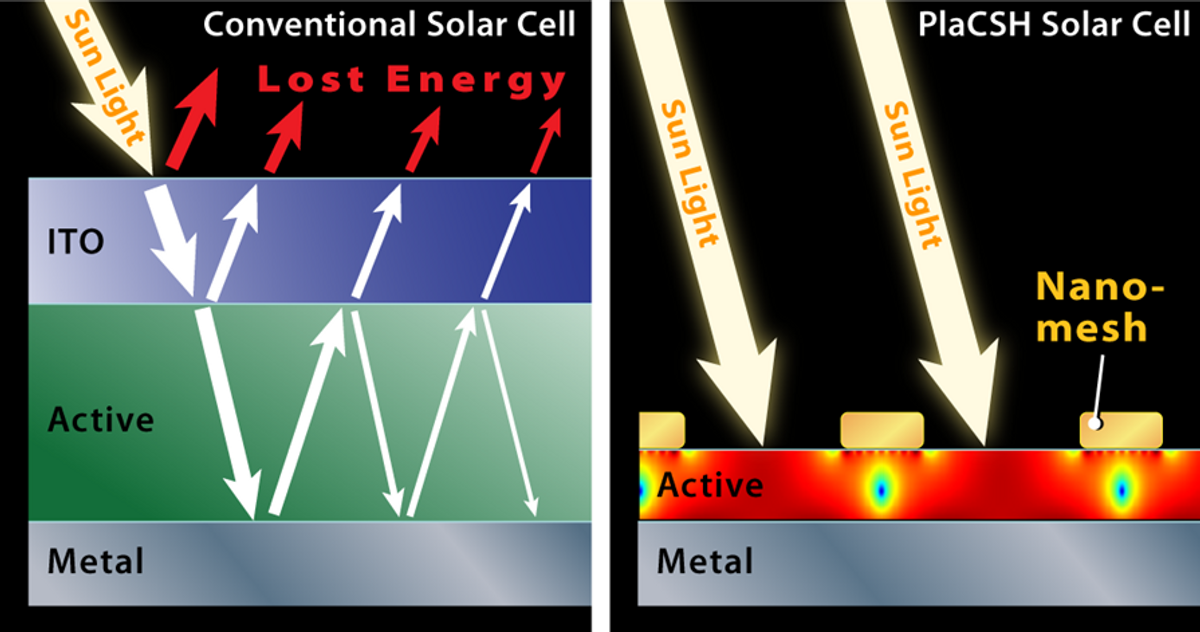

The “sandwich” as it has been dubbed is in fact a subwavelength plasmonic cavity. Plasmonics exploits the phenomenon of "photons striking small, metallic structures to create plasmons, which are oscillations of electron density in the metal." The subwavelength plasmonic cavity--or sandwich—at once dampens the reflection of light and traps light.

The result was a solar cell that reflects a mere 4 percent and absorbs 96 percent of the light that hits it. The researchers claim to have demonstrated a solar cell with this design that produces 52 percent higher efficiency in converting light to electrical energy than conventional solar cells.

These figures are for direct sunlight. On cloudy days, when sunlight hits the solar cells at an angle, the numbers are even more astounding. Efficiency is increased by an additional 81 percent over conventional solar cells, with a total increase of 175 percent.

The breakthrough of the design is the top layer of the sandwich, which is a metal mesh only 30 nanometers thick. The holes in the mesh are only 175 nanometers in diameter and are placed 25 nanometers apart. This first “window” layer means that the ITO typically used in this layer can be omitted, leading to a far cheaper design.

The bottom layer is made of the same metal films found in conventional solar cells. The top and the bottom layers are very close to each other separated only by a thin semiconducting material (silicon, plastic or gallium arsenide can be used). In the Princeton prototype an 85-nanometer-thick layer of plastic was used.

Because the design can use a variety of silicon materials, the researchers believe that it could be used in traditional silicon solar panels and reduce the thickness of the panels by a thousand fold.

Here we have a design that both significantly reduces manufacturing costs and dramatically increases energy efficiency. That’s what we call a win-win in solar cell technology.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.