Molybdenum disulfide (MoS2) started out as the next big thing after graphene in electronic applications. But that excitement started to wane somewhat when it was revealed that MoS2 contained traps—impurities or dislocations that can trap an electron or hole and hold it until a pair is completed—that limit its electronic properties.

While researchers continue to work on removing those traps in order to improve its electronic properties, others have been looking at uses for MoS2 outside of digital electronics in applications including photovoltaics and wearable electronics.

In this ever-expanding application universe, researchers at Rice University have found a method for manipulating MoS2 so that it could serve both as an improved catalyst for fuel cells and as the electrodes of supercapacitors.

In research published in the journal Advanced Materials, the Rice team, led by James Tour, developed a simple method for producing flexible films made from MoS2 that orients the material on its sides. In other words, have made the material in such a way so that the maxiumum amount of its edges are exposed.

The researchers showed that when oriented in this manner, the MoS2 can serve as an effective catalyst in the hydrogen evolution reaction (HER), a process used in fuel cells to pull hydrogen from water.

“So much of chemistry occurs at the edges of materials,” said Tour in a press release. “A two-dimensional material is like a sheet of paper: a large plane with very little edge. But our material is highly porous. What we see in the images are short, 5- to 6-nanometer planes and a lot of edge, as though the material had bore holes drilled all the way through.”

Tour added: “Its performance as a HER generator is as good as any molybdenum disulfide structure that has ever been seen, and it’s really easy to make.”

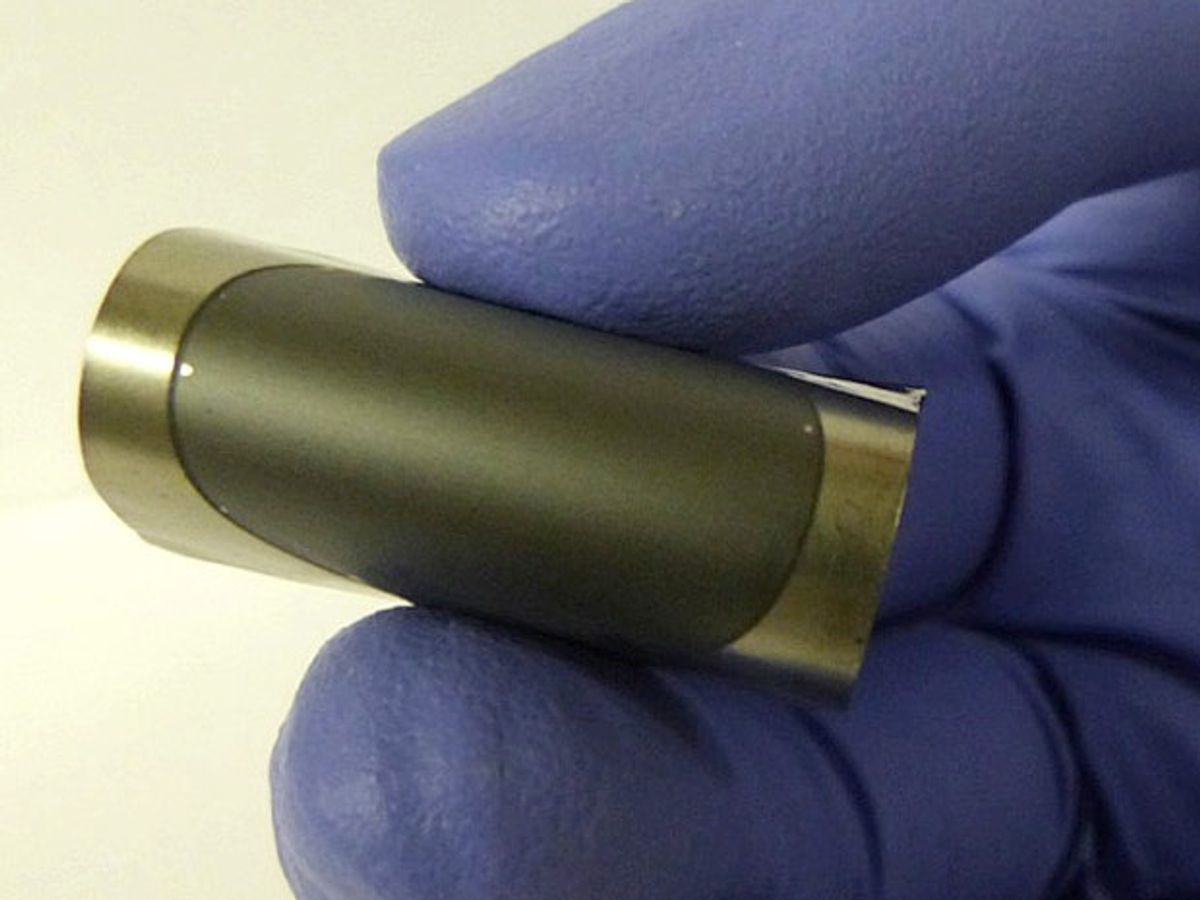

Other research has attempted to take advantage of MoS2 as a catalyst for fuel cells by standing them up on their sides. The Rice team took a different approach. First, they grew a porous molybdenum oxide film onto a molybdenum substrate through room-temperature anodization, an electrochemical process for thickening metal parts by adding a natural oxide layer.

The researchers then exposed the film to sulfur vapor at 300 °C (572 °F) for one hour. The result was molybdenum disulfide that had a flexible, nano-porous sponge-like structure.

Since the key to catalysts and to the electrodes in supercapacitors is surface area, the researchers immediately realized that the material would fit the bill for both applications. The Rice team developed a supercapacitor using the material and found the device retained 90 percent of its capacity after 10,000 charge-discharge cycles and 83 percent after 20,000 cycles.

Tour believes that this method of exploiting anodization could serve as a platform for a range of applications and devices.

“We see anodization as a route to materials for multiple platforms in the next generation of alternative energy devices,” Tour said. “These could be fuel cells, supercapacitors and batteries. And we’ve demonstrated two of those three are possible with this new material.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.