All the various permutations of electron beam induced processing have provided fairly effective nanofabrication techniques for either etching or depositing material. As important as these processes have been for nanofabrication, there has been one big problem with them: they don’t lend themselves to being scaled up.

Now researchers at Georgia Tech have developed a technique using a liquid precursor that provides fabrication at rates up to 5000 times faster than previous methods.

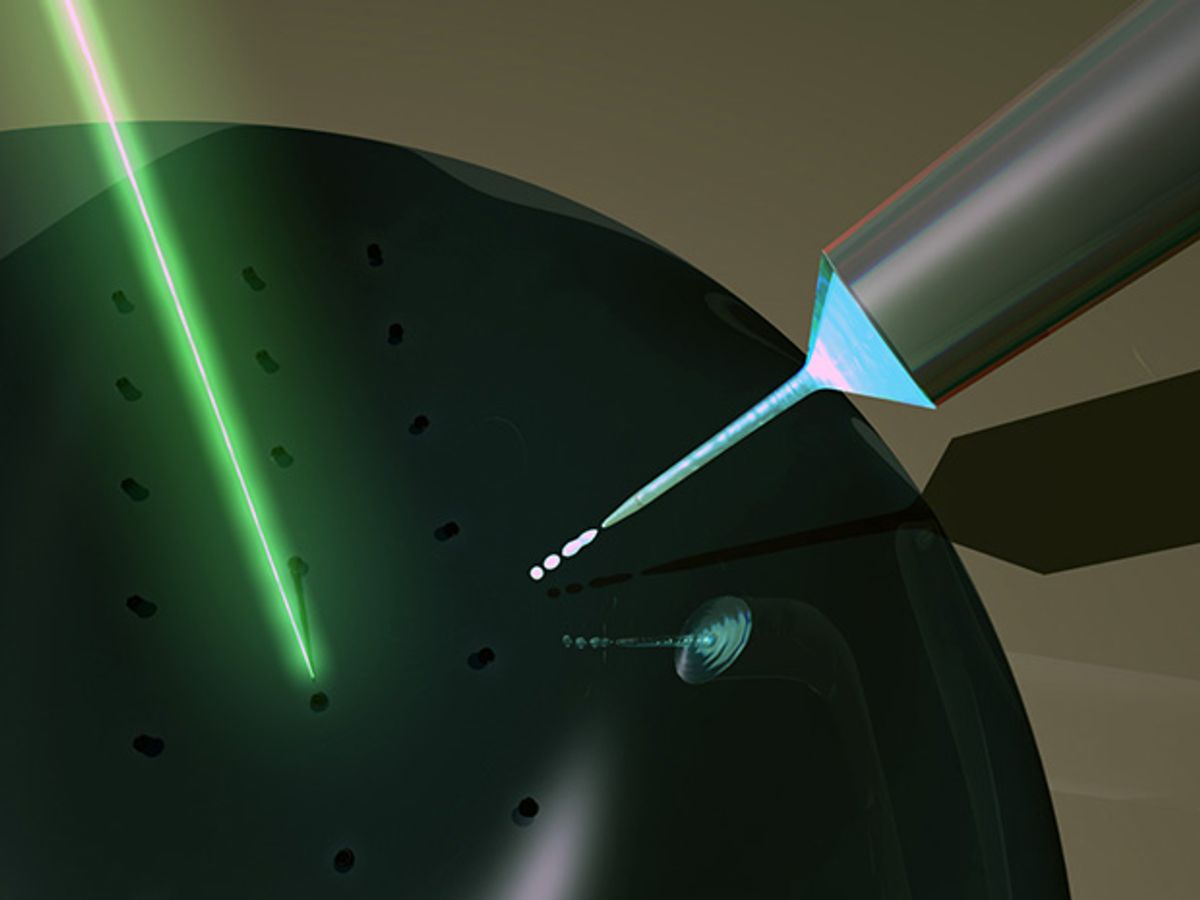

Traditionally, these methods have involved focusing an electron beam on a surface within a vacuum chamber. A precursor gas is introduced into this chamber and the molecules from this gas adsorb on the substrate. When the electron beam hits the adsorbed precursor the molecules brake into volatile and non-volatile components. Depending on the gas, either the non-volatile components stick to the surface and form a deposit, or the volatile components react with the surface and carve out an etching.

In research published in the journal Nano Letters, the Georgia Tech engineers used a liquid precursor instead of a gas. This liquid contained metal ions that produce a high-purity metal when it comes in contact with the electron beam.

“By allowing us to grow structures much faster with a broad range of precursors, this technique really opens up a whole new direction for making a hierarchy of complex three-dimensional structures with nanoscale resolution at the rate that is demanded for manufacturing scalability,” said Andrei Fedorov, a professor at Georgia Tech, in a press release. “This could provide a fundamental shift in the way this field will go.”

This 3-D nanofabrication technique should prove effective for building, according to the researchers: “new types of electrode topologies for batteries and fuel cells, vertically-stacked electronic memory, substrates for controlling cell differentiation, and tiny electrochemical conversion devices.”

In the demonstrating their new technique, the Georgia Tech researchers were able to fabricate carbon nanopillars five micrometers tall as well as wall-like nanostructures and suspended bridge-like arches that connected the nanopillars. The process produced these structures in times ranging from 2 to 40 seconds.

“We have demonstrated that we can electrospray liquid precursors inside a high vacuum environment of an electron microscope and then use electrons to facilitate useful chemical transformations,” said Fedorov. “We think this will enable scientists and engineers to make structures they had only been able to dream of before.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.