We’ve seen a variety of complicated and expensive high-tech equipment be reduced to chip-scale devices: an atomic force microscope on a chip and even a particle accelerator on a chip.

One high-tech device that has been difficult to scale down effectively is the optical spectrometer, which analyzes wavelengths of light to determine the chemical composition of an object. While nanomaterials have technically made it possible to reduce the size of spectrometers to the chip scale, these devices have not worked very well. Spectrometers must spread out wavelengths of light in order to be effective. The more you scale down the size of a spectrometer, the more you degrade its performance because the light cannot be spread out enough.

Researchers at MIT have found a way around this problem with a new approach to manipulating light on a chip-scale spectrometer. They’ve used optical switches that send the light down different pathways of varying lengths and, in so doing, have made on-chip spectrometers that rival the performance of their large-scale cousins in terms of spectral resolution and channel count, as well as signal-to-noise ratio.

The inspiration for this optical-switch approach was the good old balance scale, where just a few standard weights can be used to determine any weight, according to Juejun Hu, an associate professor at MIT and coauthor of the research described in the journal Nature Communications. In this analogy, just a few different light paths of varying lengths take the place of those standard weights. Using just a few different light paths makes it possible to determine a wide variety of wavelengths.

To clarify how this analogy relates to the actual device, Hu explains that the device consists of an interferometer, which interferes with the beams of light. Optical switches are placed on each arm of the interferometer so that light is directed to waveguides of different path lengths. The key function of this interferometer-type spectrometer is the ability to generate a large number of optical path length (OPL) differences between the two interferometer arms. In this way, each OPL difference will roughly correspond to one data point on the final spectrum (also known as the “spectral channel number”).

“Our switch network allows us to pick OPL differences from a set of fixed wave-guide lengths and combine them in arbitrary ways, just like putting multiple weights on a scale,” explained Hu.

In this arrangement, the accessible number of OPL differences will scale exponentially with the number of fixed wave-guide lengths and switching elements. A small number of switches can generate a large spectral channel number needed for precision spectroscopy, according to Hu.

This approach marks a big change from traditional on-chip spectrometers that have linear scaling, in which their performance increases only linearly with size. This is a severe penalty for on-chip spectrometers (or miniaturized spectrometers in general) due to their small size.

“We demonstrated this exponential scaling architecture such that we can realize high performance within a small on-chip footprint,” said Hu. “While our current prototype has only 64 spectral channels, we can scale our next-gen device to 1,024 channels with an only 40 percent increase of the chip area. The significance is that the technology points to a way for on-chip spectrometer[s] to truly compete with their bulk counterparts in terms of performance.”

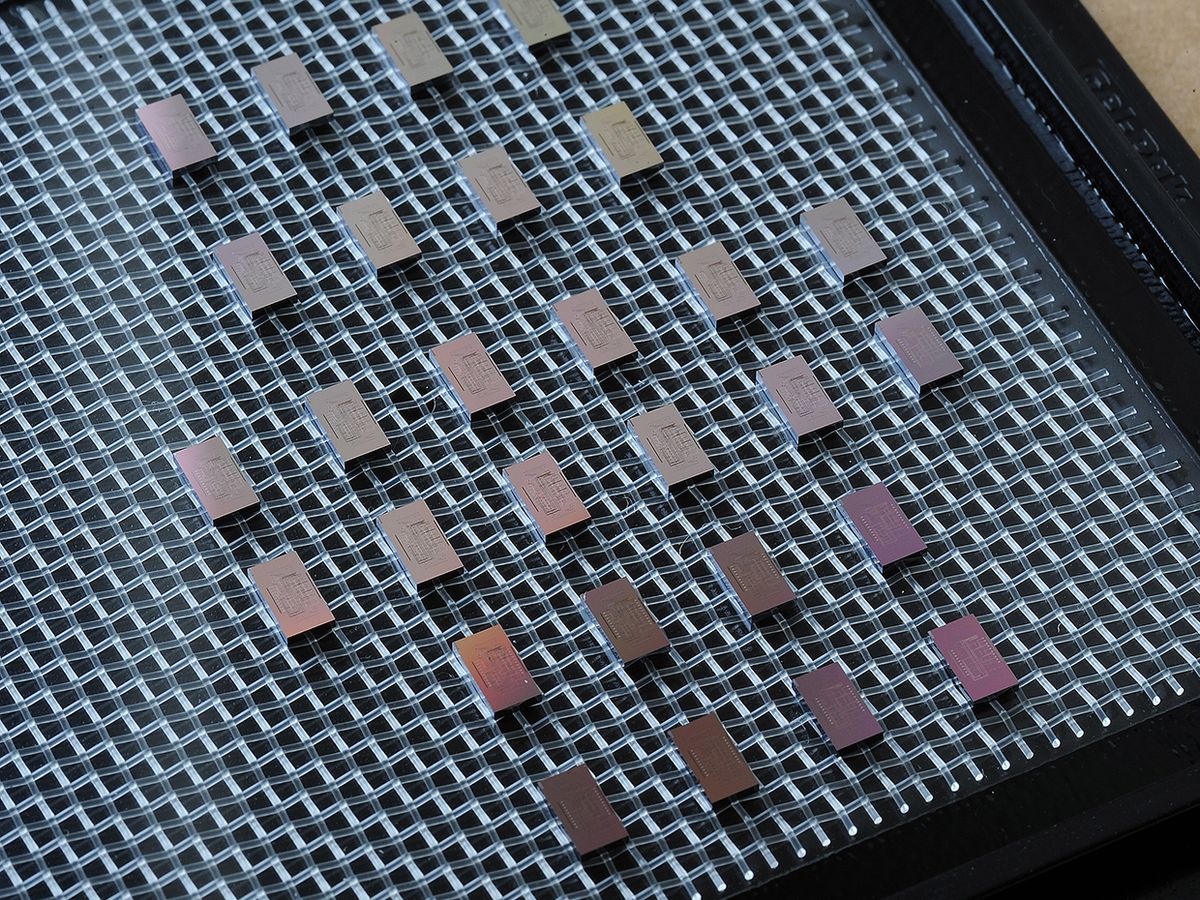

It appears that Hu and his colleagues—Derek Kita, a doctoral student and coauthor, along with research assistant Brando Miranda—have built their device with industry in mind. They have developed their prototype spectrometer through a commercial silicon photonics foundry service, meaning the device can be readily manufactured at a large scale using standard technologies.

“We also packaged the chip to become a sort of ‘plug-and-play’ module—all one needs to do in measurement is to connect the fiber connector to the light source and click a few buttons on the computer to get a spectrum, so it can be fairly easy to use,” added Hu.

For the device to start measuring objects, it will need a sensing element where the samples interact with the optical field. The spectrometer was designed with this in mind and can be seamlessly integrated with on-chip wave-guide sensors to detect different targets of interest.

At the moment, the device must be plugged into power. However, Hu believes that its power consumption is so small (less than 0.1 watts) and the acquisition time is so short (less than 0.1 seconds, even for a 1,024-channel device) that it could potentially be powered by a battery.

Whether battery powered or plugged in, the most likely applications for this on-chip spectrometer will be in spectroscopic sensing, radio frequency spectrum analysis, and optical coherence tomography, which ophthalmologists use to image the different layers of a patient’s retina.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.