On 3 January 2019, the Chinese spacecraft Chang'e-4 descended toward the moon. Countless craters came into view as the lander approached the surface, the fractal nature of the footage providing no sense of altitude. Su Yan, responsible for data reception for the landing at Miyun ground station, in Beijing, was waiting—nervously and in silence with her team—for vital signals indicating that optical, laser, and microwave sensors had combined effectively with rocket engines for a soft landing. "When the [spectral signals were] clearly visible, everyone cheered enthusiastically. Years of hard work had paid off in the most sweet way," Su recalls.

Chang'e-4 had, with the help of a relay satellite out beyond the moon, made an unprecedented landing on the always-hidden lunar far side. China's space program, long trailing in the footsteps of the U.S. and Soviet (now Russian) programs, had registered an international first. The landing also prefigured grander Chinese lunar ambitions.

In 2020 Chang'e-5, a complex sample-return mission, returned to Earth with young lunar rocks, completing China's three-step "orbit, land, and return" lunar program conceived in the early 2000s. These successes, together with renewed international scientific and commercial interest in the moon, have emboldened China to embark on a new lunar project that builds on the Chang'e program's newly acquired capabilities.

The International Lunar Research Station (ILRS) is a complex, multiphase megaproject that the China National Space Administration (CNSA) unveiled jointly with Russia in June in St. Petersburg. Starting with robotic landing and orbiting missions in the 2020s, its designers envision a permanently inhabited lunar base by the mid-2030s. Objectives include science, exploration, technology verification, resource and commercial exploitation, astronomical observation, and more.

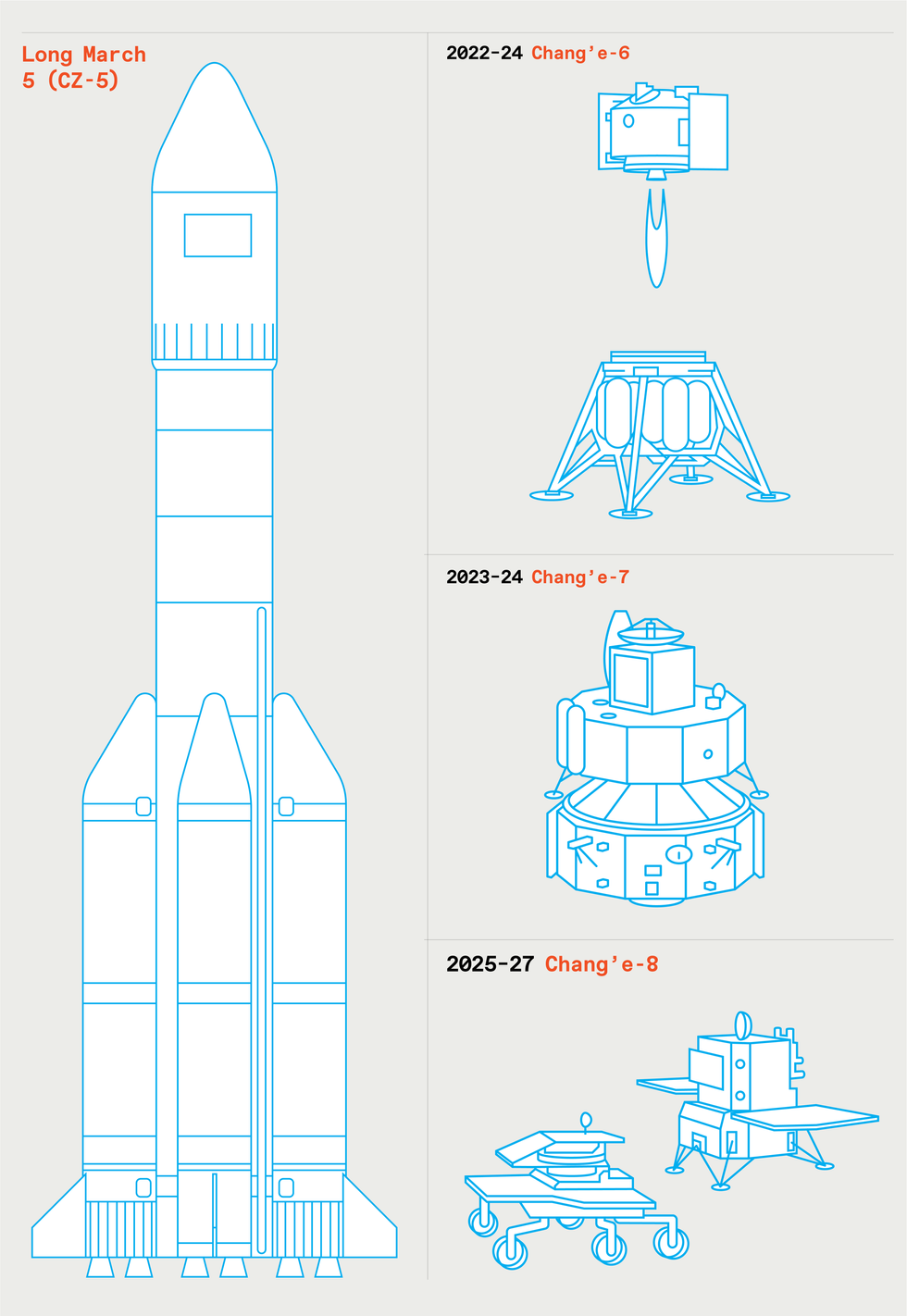

ILRS will begin with a robotic reconnaissance phase running up to 2030, using orbiting and surface spacecraft to survey potential landing areas and resources, conduct technology-verification tests, and assess the prospects for an eventual permanent crewed base on the moon. The phase will consist of Chinese missions Chang'e-4, Chang'e-6 sample return, and the more ambitious Chang'e-7, as well as Russian Luna spacecraft, plus potential missions from international partners interested in joining the endeavor. Chang'e-7 will target a lunar south pole landing and consist of an orbiter, relay satellite, lander, and rover. It will also include a small spacecraft capable of "hopping" to explore shadowed craters for evidence of potential water ice, a resource that, if present, could be used in the future for both propulsion and supplies for astronauts.

CNSA will help select the site for a two-stage construction phase that will involve in situ resource utilization (ISRU) tests with Chang'e-8, massive cargo delivery with precision landings, and the start of joint operations between partners. ISRU, in this case using the lunar regolith (the fine dust, soil, and rock that makes up most of the moon's surface) for construction and extraction of resources such as oxygen and water, would represent a big breakthrough. Being able to use resources already on the moon means fewer things need to be delivered, at great expense, from Earth.

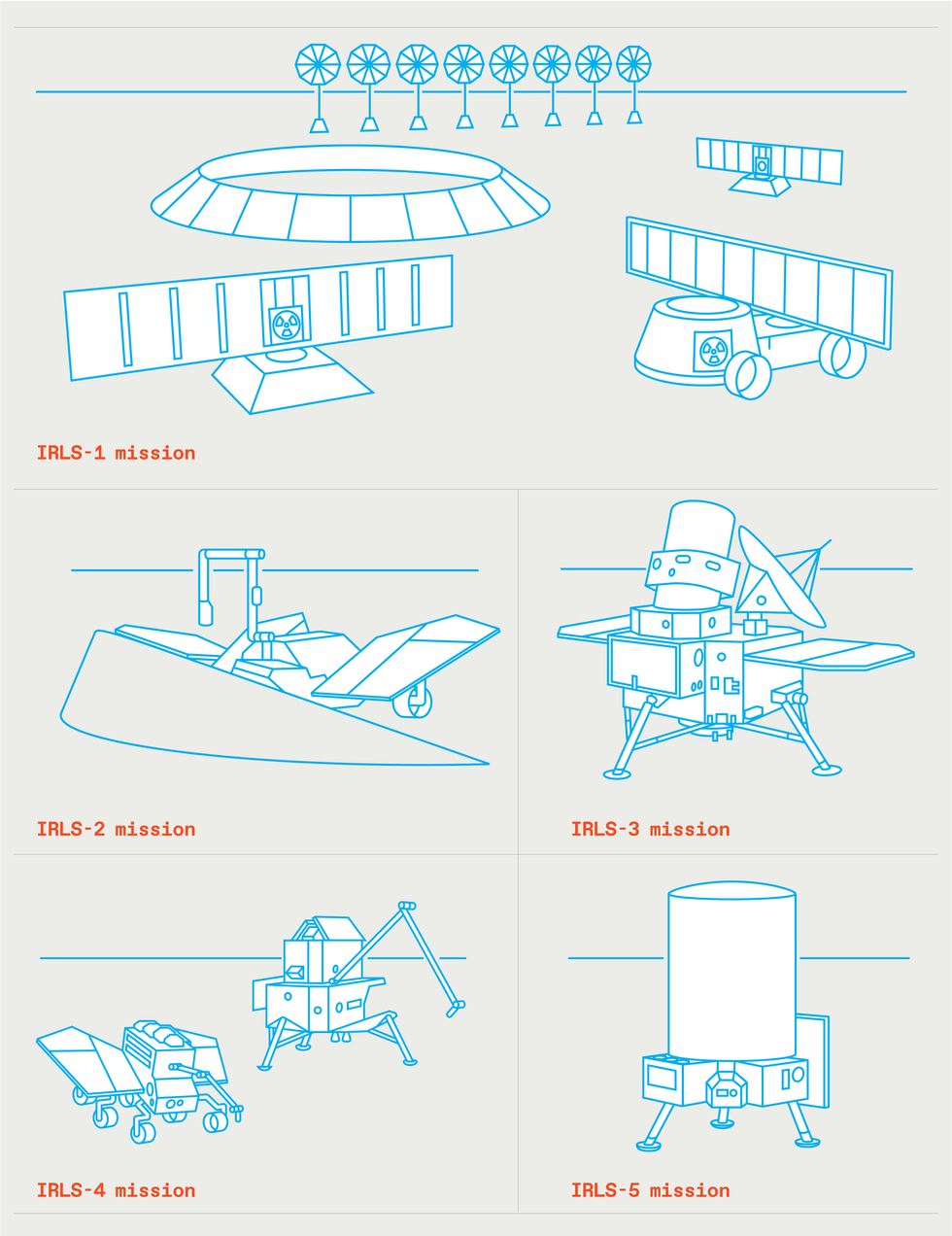

The utilization phase will begin in the early 2030s. It tentatively consists of missions numbered ILRS-1 through 5 and relies on heavy-lift launch vehicles to establish command, energy, and telecommunications infrastructure; experiment, scientific, and IRSU facilities; and Earth- and astronomical-observation capabilities. CNSA artist renderings indicate spacecraft will use the lunar regolith to make structures that would provide shielding from radiation while also exploring lava tubes as potential alternative areas for habitats.

The completed ILRS would then host and support crewed missions to the moon in around 2036. This phase, CNSA says, will feature lunar research and exploration, technology verification, and expanding and maintaining modules as needed.

These initial plans are vague, but senior figures in China's space industry have noted huge, if challenging, possibilities that could greatly contribute to development on Earth. Ouyang Ziyuan, a cosmochemist and early driving force for Chinese lunar exploration, notes in a July talkthe potential extraction of helium-3, delivered to the lunar surface by unfiltered solar wind, for nuclear fusion (which would require major breakthroughs on Earth and in space).

Another possibility is 3D printing of solar panels at the moon's equator, which would capture solar energy to be transmitted to Earth by lasers or microwaves. China is already conducting early research toward this end. As with NASA's Artemis plan, Ouyang notes that the moon is a stepping-stone to other destinations in the solar system, both through learning and as a launchpad.

The more distant proposals currently appear beyond reach, but in its space endeavors China has demonstrated a willingness to develop capabilities and apply these for new possibilities. Sample-return tech from Chang'e-5 will next be used to collect material from a near-Earth asteroid around 2024. Near the end of the decade, this tech will contribute to the Tianwen-1 Mars mission's capabilities for an unprecedented Mars sample-return attempt. How the ILRS develops will then depend on success and science and resource findings of the early missions.

China is already well placed to implement the early phases of the ILRS blueprint. The Long March 5, a heavy-lift rocket, had its first flight in 2016 and has since enabled the country to begin constructing a space station and to launch spacecraft such as a first independent interplanetary mission and Chang'e-5. To develop the rocket, China had to make breakthroughs in using cryogenic propellant and machining a new, wider-diameter rocket body.

This won't be enough for larger missions, however. Huang Jun, a professor at Beihang University, in Beijing, says a super heavy-lift rocket, the high-thrust Long March 9, is a necessity for the future of Chinese aerospace. "Research and breakthroughs in key technologies are progressing smoothly, and the project may at any time enter the engineering-development stage."

The roughly 100-meter-long, Saturn V–like Long March 9 will be capable of launching around 50 tonnes of payload to translunar injection. The project requires precision manufacturing of thin yet strong, 10-meter-diameter rocket stages and huge new engines. In Beijing, propulsion institutes under the China Aerospace Science and Technology Corp., recently produced an engineering prototype of a 220-tonne thrust staged-combustion liquid hydrogen/liquid oxygen engine. In a ravine near Xi'an, in north China, firing tests of a dual-chamber 500-tonne-thrust kerosene/liquid oxygen engine for the first stage have been carried out. Long March 9 is expected to have its first flight around 2030, which would come just in time to launch the robotic ILRS construction missions.

A human-rated rocket is also under development, building on technologies from the Long March 5. It will feature similar but uprated versions of the YF-100 kerosene/liquid oxygen engine and use three rocket cores, in a similar fashion to SpaceX's Falcon Heavy. Its task will be sending a deep-space-capable crew spacecraft into lunar orbit, where it could dock with a lunar-landing stack launched by a Long March 9.

The spacecraft itself is a new-generation advance on the Shenzhou, which currently ferries astronauts to and from low Earth orbit. A test launch in May 2020 verified that the new vessel can handle the greater heat of a higher-speed atmospheric reentry from higher, more energetic orbits. Work on a crew lander is also assumed to be underway. The Chang'e-5 mission was also seen as a scaled test run for human landings, as it followed a profile similar to NASA's Apollo missions. After lifting off from the moon, the ascent vehicle reunited and docked with a service module, much in the way that an Apollo ascent vehicle rejoined a command module in lunar orbit before the journey home.

China and Russia are inviting all interested countries and partners to cooperate in the project. The initiative will be separate from the United States' Artemis moon program, however. The United States has long opposed cooperating with China in space, and recent geopolitical developments involving both Beijing and Moscow have made things worse still. As a result, China and Russia, its International Space Station partner, have looked to each other as off-world partners. "Ideally, we would have an international coalition of countries working on a lunar base, such as the Moon Village concept proposed by former ESA director-general Jan Wörner. But so far geopolitics have gotten in the way of doing that," says Brian Weeden, director of program planning for the Secure World Foundation.

The final details and partners may change, but China, for its part, seems set on continuing the accumulation of expertise and technologies necessary to get to the moon and back, and stay there in the long term.

This article appears in the October 2021 print issue as "China's Lunar Station Megaproject."

Andrew Jones is a freelance journalist based near Helsinki. He writes about the space industry and technology with a particular focus on China's activities.