I think it's fair to say that in the last 20 years the field of prosthetics has taken a sexy turn. We've come so far from Barbie doll legs and hook arms, that it boggles the mind. People now control 5-fingered robotic hands with electrical impulses from muscles in their chest. And soon their prosthetics will directly interface with nerve endings. The "Luke arm" is a work of art, as isthe Otto Bock arm and Proto 2. But it's worth remembering something that I myself often forget: they aren't toys. And we can't measure the success of them by looking at how much fame they've bestowed upon their creators.

I most recently remembered this while listening to Kendra Calhoun speak yesterday at Worcester Polytechnic

al

Institute's annual Neuroprosthetics symposium. At this highly technical conference, it was her role to remind people of the objective—to develop prosthetics that function well enough that amputees will actually wear them, and that are inexpensive enough that they can actually afford them.

Around 30% of people with prosthetic arms stop using them and most say it's either because they hurt or they just don't work well enough. Unfortunately, as prosthetics become more functional and incorporate more technology, the cost of them will sky rocket. It's painfully clear that every patient with upper limb loss will not be able to acquire a Luke arm.

Calhoun called on the community to offer practical solutions in parallel with the grandiose projects."How do we take pieces and parts of the technology that is being advanced and put it into the mainstream?" she asked.

One solution that has to be looked at is designing prosthetics that are simply more simple. A hand is an obscenely complex structure. But not every task requires such complexity.

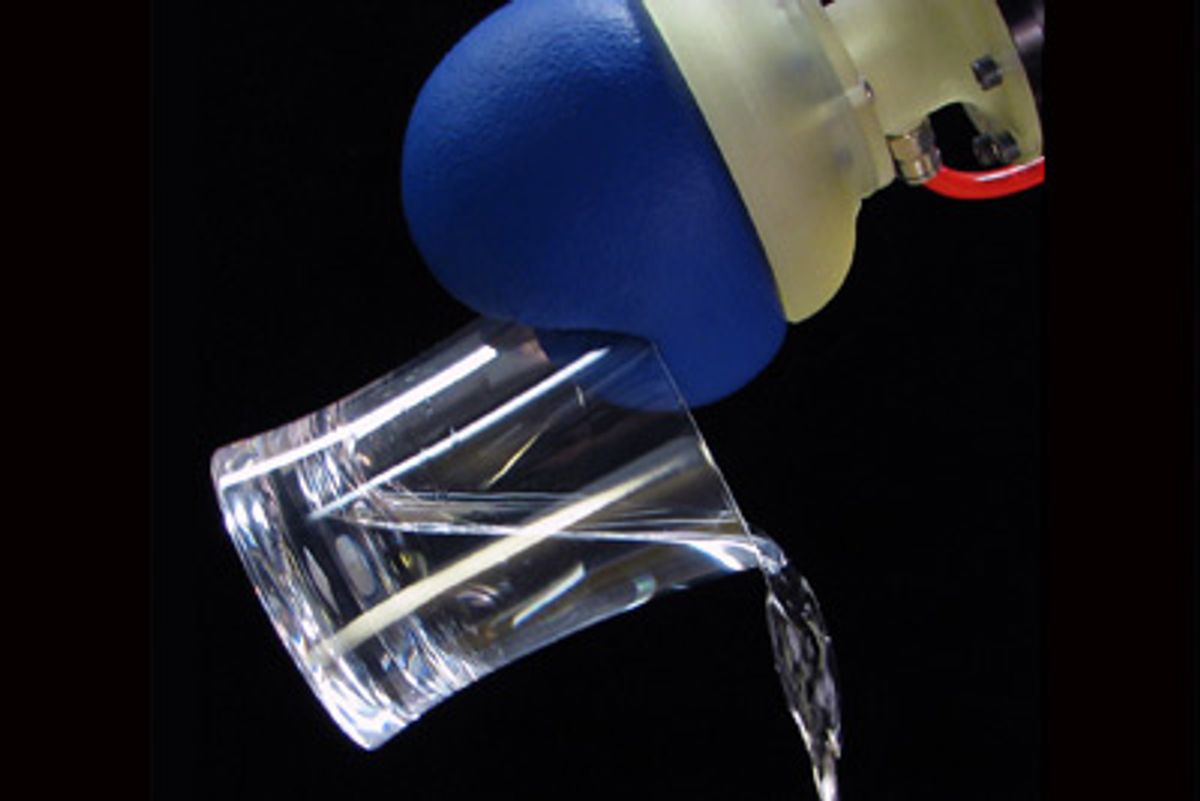

With this in mind, I was happy to run across a new design on the cover of PNAS that isn't anatomically literal. You can see how it works by watching this video:

Engineers at Cornell University (along with the University of Chicago and iRobot) introduced the concept this week. The ball is filled with coffee grinds that mold around the object you want to pick up and suck it in with a vacuum. A lot of technology is left behind here, but that also means it will be less expensive.

While reproducing the elegance of our anatomy is noble, it may not always be necessary or practical. And the more noble task could very well be less sexy. Many would benefit if we channeled a bit of our adulation (and funding) to those projects that are churning out the prosthetics we'll actually see on the streets.

(Image courtesy of John Amend)