Frequent fliers will hope Mitsubishi Electric’s development of 300-gigahertz tomographic technology makes good on its promise to usher in walk-through security gates at airports and other locations. If the company’s current prototype development successfully overcomes the challenges of cost and speed, then you can expect to see the end of standing about in stocking feet and waiting in line to enter an X-ray scanning booth before boarding your plane. Instead, the technology will make it possible to image objects, even when concealed, on a person walking straight through the security gate.

“The lack of details in the press release suggests that the technology is at a very early stage,” says Daniel Mittleman, a professor of engineering at Brown University. “So it’s difficult to know what its new capabilities might be, although they could be significant. Numerous groups around the world are working on similar technologies, so we can expect them to have a big impact.”

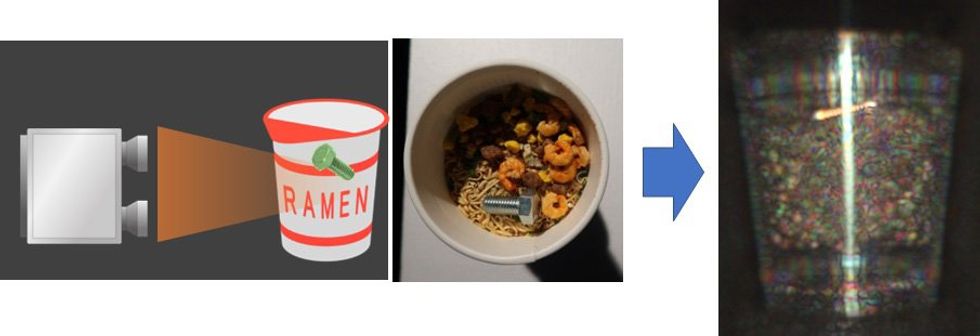

To test the concept, the researchers at Mitsubishi Electric used off-the-shelf components and devices, including an arbitrary waveform generator capable of 25 gigasamples per second to generate millimeter-band radar signals and frequency converters for generating subterahertz signals.

The reflected subterahertz signals from the targeted object are mixed with the transmitted signal for down-converting to an intermediate frequency (IF) signal with a 30-megahertz bandwidth and digitized by a local oscillator from the arbitrary waveform generator. The result is sent to an analog-to-digital converter in a computer and stored in an 11-terabyte RAID storage device for offline processing by a digital signal processor and converted into a virtual 3D tomographic image.

“We have confirmed the effectiveness of the method after testing it in the 300-gigahertz-band range,” says Akinori Taira, chief researcher at Mitsubishi Electric’s Communications Technology Department in Ofuna, 45 kilometers south of Tokyo. The test setup and results are described in a paper (in Japanese and awaiting publication) that was presented at the March general conference of the Institute of Electronics, Information and Communication Engineers held in Saitama, 80 km north of Tokyo.

During testing, the researchers used just one receiving antenna. To simulate a one-shot, one-direction operation, the antenna was moved repeatedly using an XY stepper to measure each reflected signal.

“This took a number of minutes,” says Akihiro Okazaki, a senior manager working together with Taira. “But before the commercial stage of development, we will use hundreds of antennas in arrays. So we estimate the measurement time will be reduced to less than one millisecond.”

For the task of recognizing a hidden object such as a knife or gun in an image, Taira says they are looking at artificial-intelligence and machine-learning image-recognition technology already in use in optical security camera systems. “That technology is similar to what we want, although it will need modifying,” Taira says. And depending on the application, he says the system will then automatically notify the operator by using an audio or visual warning system.

What makes the system interesting is Mitsubishi Electric’s virtual-focus imaging of moving objects uses a single irradiation from one direction. By contrast, conventional computed tomography irradiates the object multiple times from various angles.

The one-shot, one-direction scheme uses a two-step approach—measuring the object, and then analyzing and recreating it virtually. First, multiple-input multiple-output (MIMO) radar signals are directed at the subject from multiple antenna elements and the reflected signals are received by an equally large number of antenna elements. “So first we extract the IF signal to get the MIMO’s channel state information (CSI),” says Taira. This procedure enables the antennas to gather the known properties of the MIMO signals, including power and phase data, which are sent to the computer and stored in cache memory.

The second step takes place within the computer, using a digital signal processor. The DSP divides the scanned area into spatial positions called voxels, which have strong reflection gain that can be estimated. A virtual beam is created from the CSI data to scan the voxels vertically, horizontally, and slice by slice for depth to create a 3D image of the object with millimeter accuracy from the 2D data, which is then displayed.

“This operation requires an enormous number of arithmetic calculations,” says Taira. “But we have developed a fast Fourier transform-based calculation method and reduced the number by a factor of several hundred.” Currently, the process takes about 20 seconds to complete, “but we will bring it down to 1 second in the future by refining the algorithm and using [field programmable gate arrays] and graphics processing units.”

In a walk-through security-gate use case, four sensor antenna units will be installed in arbitrary locations to take images of a subject several times from different angles.

“This will eliminate blind spots during the walk-through [which] we assume will take 1.5 seconds,” says Okazaki. And with each unit producing only about 200 milliwatts, about the same as a cellphone, “there are no health concerns,” he says. In addition, Taira notes that the properties and effects of terahertz waves are generally considered to be similar to those of millimeter waves, the use of which has been standardized.

“The issue of health risks related to exposure to subterahertz radiation such as this is a topic of some discussion,” says Mittleman. “But there are good reasons to believe that it is even safer than exposure to EM waves at lower frequencies, such as used in cellphones or Wi-Fi base stations, which are considered safe at low power levels. For one thing, the penetration depth into living tissue is much smaller at these higher frequencies.”

Mitsubishi Electric is also targeting production-line-inspection applications with the technology. But the researchers agree that to compete successfully with established X-ray security systems, besides achieving their speed and miniaturization targets, they will also have to make the system cost effective. That is out of the question today. However, as Taira points out, toward the end of the decade when they expect to be able to commercialize their imaging system, 6G cellular services incorporating terahertz frequencies should begin rolling out, and so terahertz devices will be more plentiful and available at more competitive prices.