Researchers have used a 3D printer and six novel bioinks to build a “heart-on-a-chip” that can serve as a living organ for drug testing. The device, developed by a team of bioengineers out of Harvard’s Wyss Institute, was described this week in Nature Materials.

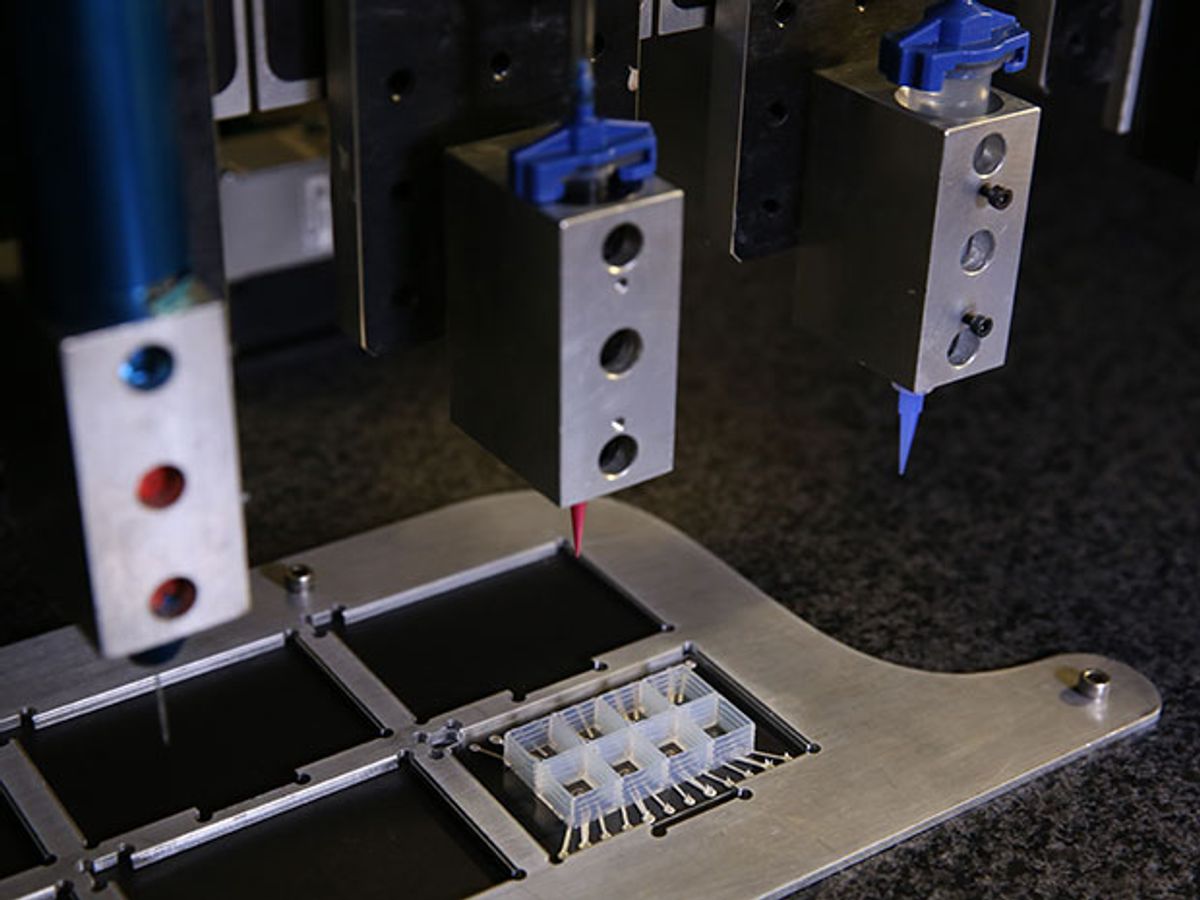

The Wyss team’s heart is the first organ-on-a-chip to be built with a 3D printer. The system can be programmed to print different types of organ-chips, and allows for automated production. “The whole field has been building one-offs [of organ-chips] that aren’t amenable to mass manufacturing,” says Kit Parker, a bioengineer at Wyss and an author of the paper. “We solved that.”

That may be enticing to pharmaceutical companies and academic labs that want to speed up the drug screening process. With mass produced organ-chips, those groups can test how living tissue might respond to a new drug without using animals or humans as test subjects.

The Wyss team’s device also automates the process of collecting data from the organ. By building sensors into the chip, the team enabled the device to spit out data on how it’s doing. That takes away the laborious process of optically measuring an organ-chip’s response, says Jennifer Lewis, a materials scientist at Wyss and an author of the paper. In the past, we “were literally sitting over a microscope taking video...and then going back in to do image analysis to try to measure” the organ’s response, she says. “It’s very difficult and imprecise,” she says.

The Wyss heart-on-a-chip is printed in one shot. After it’s completed, heart muscle cells, called cardiomyocytes, are added and grown in the chip’s eight wells. Scientists can then expose the cells to drugs or stressful environmental conditions and measure them to see how they perform.

The key indicator is the strength of the beat of the cells—like the strength of a beating heart. To measure this, each well contains a hairpin-shaped cantilevered flap made out of a piezo-resistive, biocompatible ink. Heart cells are added to the wells, and when they beat, they cause the cantilevered flap to elongate. That change in resistance creates a measurable change in electrical response.

“The resistance varies depending on how well the cells are beating,” says Lewis. A drug that’s bad for the cells diminishes the strength of the beat.

The Wyss team programmed the system to print a heart, but any muscular organ can be replicated using this chip design, says Parker. The gut, airways, vascular system, tongue, and skeletal muscle are all candidates for this type of mass manufactured organ-chip, he says.

The 3D-printed heart-on-a-chip is the most recent in a slew of organ-chips developed by the Wyss group. Previously developed chips, including a lung, gut, kidney, tongue, and heart, were built as one-offs using multi-step microfluidic processes. The projects are part of a larger effort at Wyss to develop 10 organ-chips and link them together to mimic the human body. The work is supported by a US $37 million grant from DARPA, the U.S. military’s research arm.

Emily Waltz is a features editor at Spectrum covering power and energy. Prior to joining the staff in January 2024, Emily spent 18 years as a freelance journalist covering biotechnology, primarily for the Nature research journals and Spectrum. Her work has also appeared in Scientific American, Discover, Outside, and the New York Times. Emily has a master's degree from Columbia University Graduate School of Journalism and an undergraduate degree from Vanderbilt University. With every word she writes, Emily strives to say something true and useful. She posts on Twitter/X @EmWaltz and her portfolio can be found on her website.