Robots that fight fires, cars that drive themselves, clothes that prevent illness—are they the stuff of science fiction? Or are they more likely than we think? “Life in 2030,” a one-hour special from the radio series Engineers of the New Millennium, explores the latest discoveries to give listeners an idea of how technology will shape our lives in the not-too-distant future.

The Impact of Invisible Nanotechnology

TRANSCRIPT:

Susan Hassler: Whatever the future holds for us in 2030, I think it’s safe to say that nanotechnology will play a huge role.

Dave Guston: As it evolves, it is going to be anywhere and everywhere, the same way that computer chips are not just in computers but they’re in toys, they’re in automobiles, they’re in pens

Phil Ross: Dave Guston is not an engineer working on some new nanomaterial. He’s actually a political scientist, head of the Center for Nanotechnology in Society at Arizona State.

Susan Hassler: We wanted to know how nanotechnology is going to change society over the next 20 years, but as Glenn Zorpette found out, it may be society that changes nanotechnology

Glenn Zorpette: Right—because nanotechnology will be shaped by society—just how much is partly up to its citizens.

Dave Guston: If they want to have a say in what their socio-technical environment looks like in 2030, they’ve still got the opportunity to do that. They don’t have to wait until the nanotechnology product is on the shelf, until the nanotechnology system is entirely embedded in the world that they live.

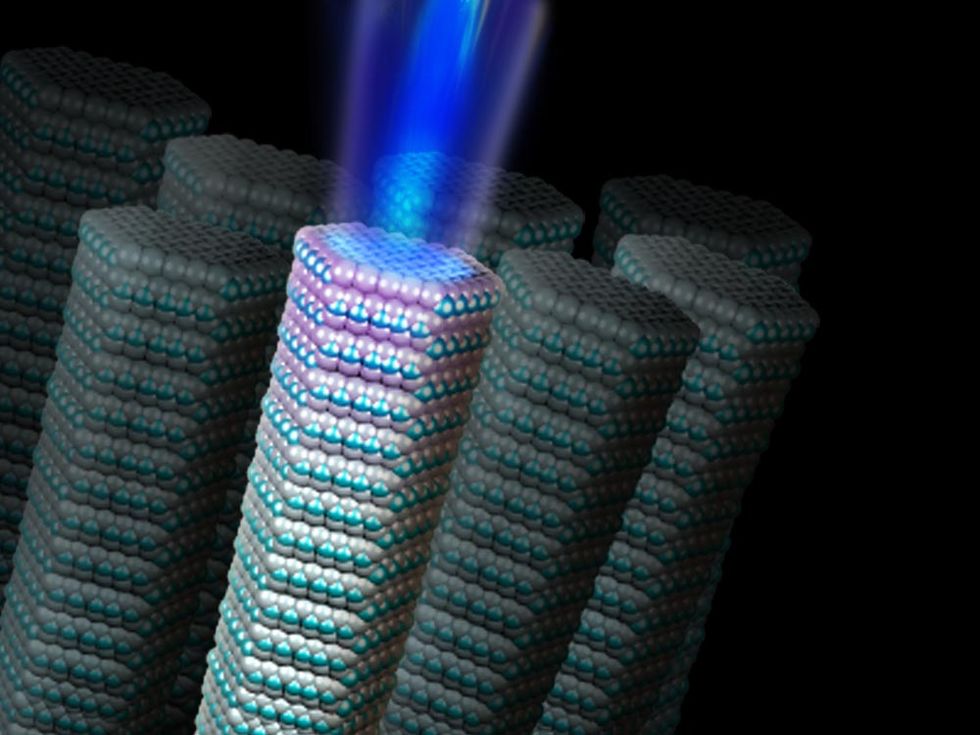

Glenn Zorpette: So, here’s how it works: Nanotechnology researchers study and manipulate matter smaller than the size of individual atoms and molecules. Nanometers are so small that one sheet of paper is 100 thousand nanometers thick. And at that scale, matter behaves differently, opening the door to amazing nanomaterials and nanosystems—from futuristic sounding concepts like a cloaking device that can render objects invisible to innovations that could very well be on the market before 2030, like more effective cancer therapies, more efficient batteries, and cheaper solar cells

Mark Wiesner: I mean the benefits are tremendous, right? They’re going to give us better, cleaner sources of energy. They’re going to improve nanomedicine. They’re going to really revolutionize the way we live.

Glenn Zorpette: Because the behavior of nanomaterials and systems is new territory, it’s been important to study their potential risks and secondary implications along with their special capabilities

Like Dave Guston, environmental engineer Mark Wiesner runs a center working on future scenarios—Duke University’s Center for the Environmental Implications of Nanotechnology, or CEINT for short

Mark Wiesner: This is the CEINT mesocosm facility. And it simulates a freshwater wetland. So, you have some of these plants, which were selected….

Glenn Zorpette: Wiesner and his team are studying how nanomaterials—in this experiment, silver nanomaterials—interact with plants, microbes, and fish in an ecosystem

Mark Wiesner: We do all these experiments in a lab and the nanomaterials that really will be seen in the environment, the nanomaterials that people and organisms will see, are going to be very different from the ones that come out of the lab. They change. Nature changes them.

Helen Hsu-Kim: We’re now realizing that really looking at transformations of these nanomaterials in the environment is one of the key things that we have to be able to understand to be able to say something about their potential risks.

Glenn Zorpette: Geochemist Helen Hsu-Kim and the other researchers are designing better ways to evaluate nanomaterials. Their goal is to map potential risks and develop a framework for decisions that society will have to make in the future.

Helen Hsu-Kim: That’s what’s exciting about this new approach we’re taking in terms of being proactive about trying to look at unintended consequences of a new industry, a new technology.

Mark Wiesner: What we’re doing are developing methods that allow us to take the most recent information we have, incorporate it mathematically into these descriptions of risk and give us an understanding of not only what our best guess of the risk might be but really, perhaps more importantly, what’s the uncertainty of the risk.

Glenn Zorpette: Back in Arizona, at the Center for Nanotechnology in Society, one of their projects places social scientists in the lab with researchers. Here’s Dave Guston again.

Dave Guston: And it starts off very simply where the social scientist will ask, “What are you doing? Why are you doing that? Could you do it any differently? What do you hope to get out of it?” And those very simple questions create this Socratic dialogue through which the scientists and engineers begin to reconceptualize some of what they’re doing in their research and understand that their research and the decisions that they make in the laboratory have different kinds of consequences for people who are outside of the laboratory, for the rest of us in society.

Glenn Zorpette: Cynthia Selin runs the center’s Anticipation and Deliberation program.

Cynthia Selin: Much of what I’m doing when I’m creating spaces for reflection about futures with scientists, with policymakers, with businesspeople is really to try to make explicit their expectations of the future, to lay out on the table what kind of changes they think are on the horizon and what they’re working towards, and it’s really that making more real and tangible the future that’s of great value and that I hope will maximize the positive benefits of nanotechnology and minimize the negative ones.

Glenn Zorpette: Because no one can say for certain what the future holds, these scientists and engineers prefer to…anticipate

Dave Guston: Which is looking toward the future, not looking at the future as a thing, as if one thing is going to happen in the future that we can predict, but looking toward a variety of plausible futures that we can begin to act around and toward in things that we do today.

Glenn Zorpette: I’m Glenn Zorpette.