With the aid of crystals known as perovskites, solar cells are increasingly breaking records in how well they convert sunlight to electricity. Now a new automated system could make those records fall even faster. North Carolina State University’s RoboMapper can analyze how well perovskites might perform in solar cells, using roughly one-tenth to one-fiftieth the time, cost, and energy of either manual labor or previous robotic platforms, its inventors say.

The most common solar cells use silicon to convert light to electricity. These devices are rapidly approaching their theoretical conversion efficiency limit of 29.4 percent; modern commercial silicon solar cells now reach efficiencies of more than 24 percent, and the best lab cell has an efficiency of 26.8 percent.

One strategy to boost a solar cell’s efficiency is by stacking two different light-absorbing materials together into one device. This tandem method increases the spectrum of sunlight the solar cell can harvest. A common approach with tandem cells is to use a top cell made of perovskites to absorb higher-energy visible light and a bottom cell made of silicon for lower-energy infrared rays. Last year scientists unveiled the first perovskite-silicon tandem solar cells to pass the 30 percent efficiency threshold, and last month another group reported the same milestone.

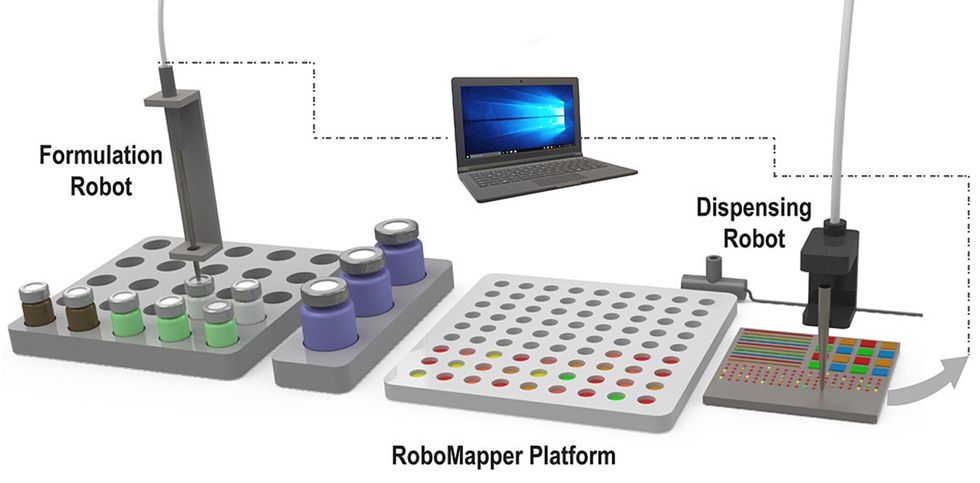

Conventional materials research has scientists prepare a sample on a chip and then go through multiple steps to examine it using different instruments. Existing automation efforts “tend to emulate human workflows—we tend to process materials one parameter at a time,” says Aram Amassian, a materials scientist at North Carolina State University, in Raleigh.

RoboMapper’s greatest reduction in environmental impact came from improved energy efficiency during testing.

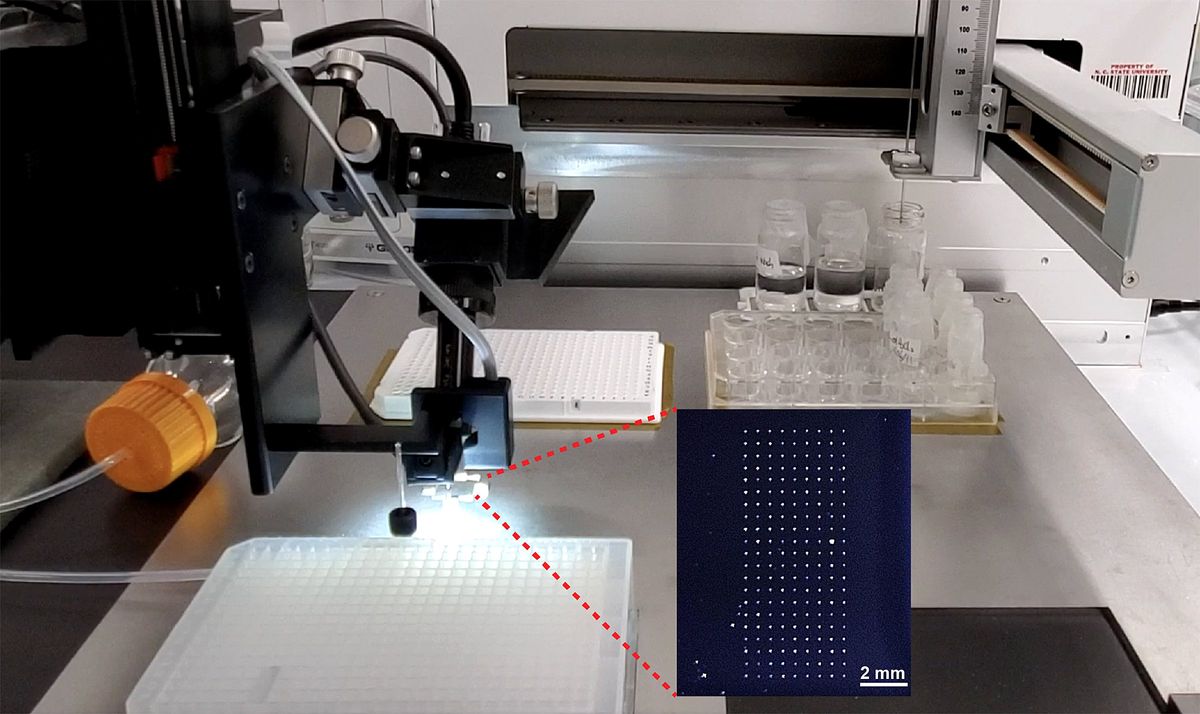

However, modern genetics and pharmaceutical analysis often achieves high throughput by placing dozens of samples on each plate and examining them all at once. RoboMapper also follows this strategy, using printing techniques to miniaturize the material samples.

“We’ve benefited a lot from hardware interoperability with biology and chemistry, such as in liquid handling,” Amassian says. However for RoboMapper, Amassian and his team had to develop new protocols for handling perovskite materials and different characterization experiments from what you’d find in chemistry automation. “One particular development we had to make is to make sure that characterization instruments can handle the high density of materials on a chip with automation. This required a little bit of engineering on both the hardware and software side.”

One key to saving time, energy, material, and money was to shrink the sample size by a factor of 1,000. “The print size is on the order of 50 to 150 [micrometers], while most other tools create samples on the order of centimeters,” Amassian says. “Typically, we print picoliter to nanoliter volumes while other platforms print or coat microliters.”

Perovskite Properties for Pennies

In the first tests of RoboMapper, the scientists analyzed 150 different perovskite compositions. In all RoboMapper was 12 percent the cost, nine times as fast, and 18 times as energy efficient as other robotic platforms. And it was 2 percent the cost, 14 times as fast, and 26 times as energy efficient as manual labor.

“We set out to build a robot that can generate large material libraries so that we can build datasets for training AI models in the future,” Amassian says. Such an AI could then predict which perovskite structures will perform best.

The researchers focused on perovskites’ stability, which is a major challenge when it comes to tandem cells. Perovskites tend to degrade when exposed to light, losing the properties that made them desirable in the first place, Amassian explains.

The scientists analyzed perovskite structure, electronic properties, and stability in response to intense light using optical microscopy, microphotoluminescence spectroscopy mapping, and synchrotron-based wide-angle X-ray scattering mapping. This experimental data was then used to develop computational models that identified a specific composition that the researchers predicted would have the best combination of attributes.

“These models are now available for others to use,” Amassian says. He notes they are now in talks with leading tandem solar cell research groups.

Unexpectedly, the scientists found that RoboMapper’s greatest reduction in environmental impact came from improved energy efficiency during testing.

“We and others did not realize this, because electricity used by instruments in the lab is unseen, whereas materials and supplies are tangible,” Amassian says. “RoboMapper was designed in part to address this insidious problem by placing dozens of materials in the same measurement tools and significantly reducing the amount of time it needs to be powered on to collect data. We showed that tenfold reduction in carbon footprint and other negative environmental impacts can be achieved.”

In the future, “we will continue to search for newer and better perovskites,” Amassian says. “We’re also actively looking at organic solar-cell materials to find compositions that are stable for solar-energy applications. The ability to test dozens of compositions under intense simulated sunlight helps save tremendous time and energy.”

The scientists detailed their findings online 25 July in the journal Matter.

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.