Solar cells based on crystals known as perovskites have advanced by leaps and bounds in recent years. Now scientists have found a way to increase perovskite solar cell size while maintaining the device’s high conversion efficiencies.

In the span of less than a decade, the conversion efficiency of perovskite solar cells has grown from 3.8 to 22.1 percent, an unprecedented rise in the field of photovoltaics. Such devices are also appealing because they are much cheaper to make than the silicon wafers used in conventional solar cells.

However, a major drawback of high-efficiency perovskite solar cells is how small they generally are, ranging from 0.04 to 0.2 square centimeters. Currently, the best conversion efficiency of a perovskite solar cell larger than 1 square centimeter is 15.6 percent.

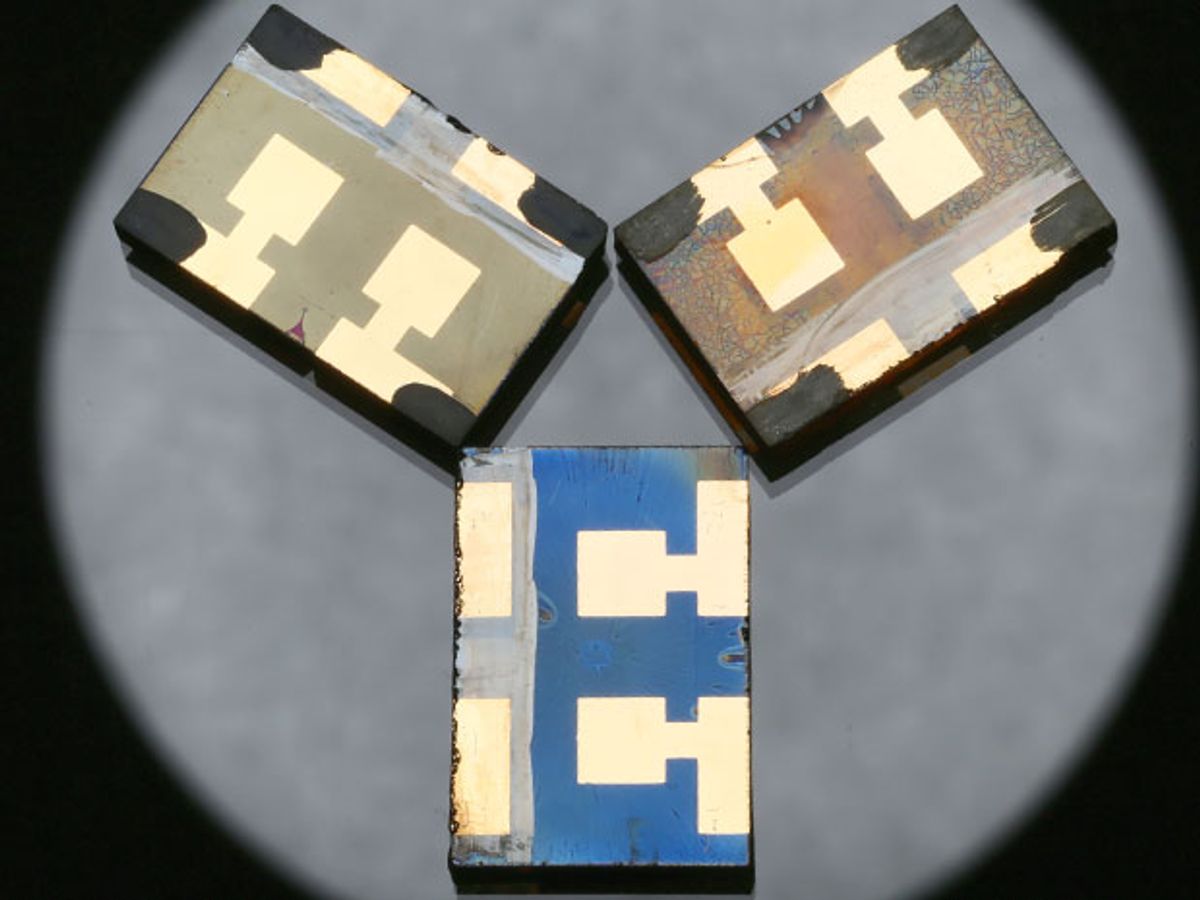

Now scientists have created perovskite solar cells more than 1 square centimeter in size with an average conversion efficiency of 19.6 percent and a maximum efficiency of 20.5 percent, matching the performance of conventional thin-film solar cells of similar sizes.

"We have achieved an unprecedented efficiency level at a larger size, which has been a problem so far," says study co-author Michael Grätzel, director of the Swiss Federal Institute of Technology Lausanne's Laboratory of Photonics and Interfaces. "How high can we go with efficiency? Theoretical efficiencies are around 30 percent. While we might not get to theoretical efficiencies, we can still go much higher than we have currently."

Conventional manufacturing techniques for perovskite solar cells precipitate solid perovskites from a solution by dripping a chemical known as an "anti-solvent" into the center of the perovskite film as it is spun. However, this results in blotchy impurities and ultimately leads to defects in the perovskite film. In addition, the anti-solvents currently used are toxic and harmful to the environment, hampering their large-scale application, Grätzel says.

Instead, the researchers employed an anti-solvent-free technique called vacuum-flash solution processing. This new technique uses a few seconds of mild vacuum to dry up solvent and help trigger precipitation of solid perovskite. In combination with rapid heat annealing, this method resulted in thin, smooth, highly oriented crystalline perovskite films.

"We can very simply get remarkable results compared to anti-solvent methods," Grätzel says. "We are now excited about scaling up to make bigger modules."

The scientists detailed their findings online June 9 in the journal Science.

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.