Organic semiconductors are versatile materials used in many flexible displays and sensors. The materials, which are typically made of conducting carbon-based polymers, can bend and fold, but they tend to degrade quickly compared to traditional electronics. These organic semiconductors are useful in bendy biosensors and other consumer devices, including wearables, smart tags, electronic textiles; however, they’re expensive and difficult to manufacture, and they have significant environmental costs.

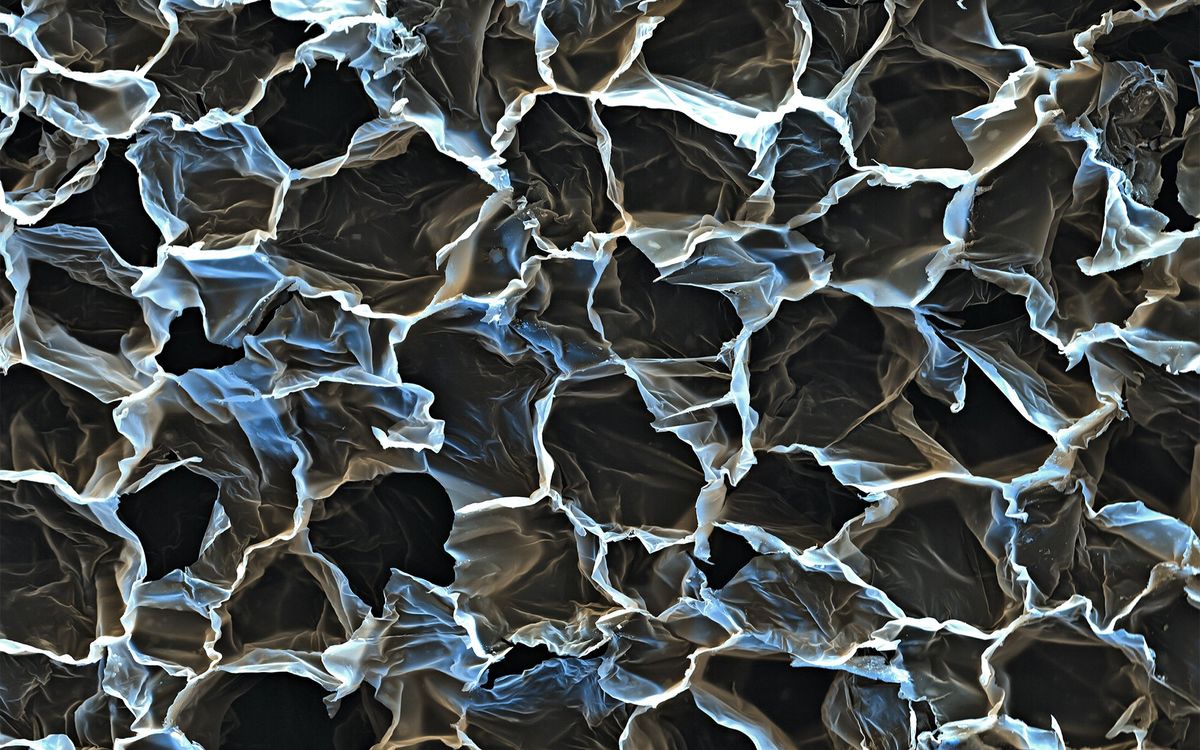

Researchers at KTH Royal Institute of Technology and Stockholm University, both in Stockholm, have found that mixing an organic semiconductor with a polystyrene—the common, inexpensive plastic used for consumer products like packing peanuts, foam food packaging, and DVD cases—improved the electrical performance of the semiconductor while requiring only one sixth the amount of organic material.

Organic bioelectronics “offer new possibilities, but today they’re not so easy to make,” says Anna Herland, associate professor at KTH Royal Institute of Technology. “Remarkably enough, when we put in that insulating material, we created a blend that performs better.” Reducing the amount of semiconductor material also makes the resulting electronic devices more sustainable. The researchers published the findings on 3 March in Advanced Materials.

Replacing Semiconductor Material

High quality organic materials used in bioelectronic devices, which are designed to conduct both ions and electrons, are currently synthesized in complex processes that involve several purification steps and toxic substances, says Erica Zeglio, assistant professor at Stockholm University.

Meanwhile, polystyrene—the plastic Zeglio and Herland added to the semiconductors—is commercially produced at large scales and a fraction of the cost. “We are moving toward new technology that can replace standard semiconductors like silicon,” says Zeglio.

Organic semiconductors also tend to have limited durability compared to traditional electronics; over time, the devices degrade and the drain current drops. The researchers decided to add an insulating material in an attempt to address this issue, inspired by other researchers who had done so in a different type of electronic device. They were initially skeptical it would work, but found the blend of materials did improve stability. After 60 minutes of operation, the blended material retained 77 percent of the initial drain current, compared to 12 percent for the pure semiconductor.

![A technical diagram showing [p(N-T)] mixing with [PS]](https://spectrum.ieee.org/media-library/a-technical-diagram-showing-p-n-t-mixing-with-ps.jpg?id=51943570&width=980)

Herland hopes this finding may inspire other researchers to consider working with new materials. “This method can allow them to try materials that they had discarded because they weren’t stable enough,” she says.

Improved Performance

Surprisingly, diluting the semiconducting material with an insulator also resulted in electrical performance three times as good as that from an undiluted semiconductor. That performance is measured by a metric that takes into account two factors: How fast electrons are conducted, and how many ions can be stored in a given volume.

Unlike many other transistors, which depend on the accumulation of charges on an interface, “this material has electronic and ionic transport properties through the bulk of the material,” Herland says. “Here, you play with the whole volume.”

The mechanism for the improvement is still unclear, though Herland says several factors could be at play. For instance, the blend of material could help avoid damaging changes in that material, or organize it in a way that promotes ion and electron movement. She hopes to gain a better understanding through future research.

Additionally, because organic materials are typically only available in small volumes, the testing occurred on a small scale—a common limitation in this field of research, Herland says.

The research is a major advance for organic electrochemical transistors, according to Antonio Facchetti, a professor at Georgia Institute of Technology. Because these devices typically operate by moving ions through a hydrated medium, Facchetti would have suspected a hydrophilic material would be a better choice. However, the researchers found that a hydrophobic polymer worked best. “It is very surprising these devices work at all,” Facchetti says. He also noted that the long-term durability of the material remains limited.

In the future, the team hopes to find other routes to reduce the environmental impact of the devices, such as in the synthesis process. “We are trying to move toward sustainability from different directions,” says Zeglio. That also includes the application; the team is currently working to develop the technology for use in food waste sensors.