The two-dimensional material graphene is basically all surface. This makes it highly sensitive to atoms or molecules because its entire volume can serve as a sensor surface. This has led researchers and industry to exploit graphene as both a biosensor and an electronic sensor for detecting the smallest changes to an environment.

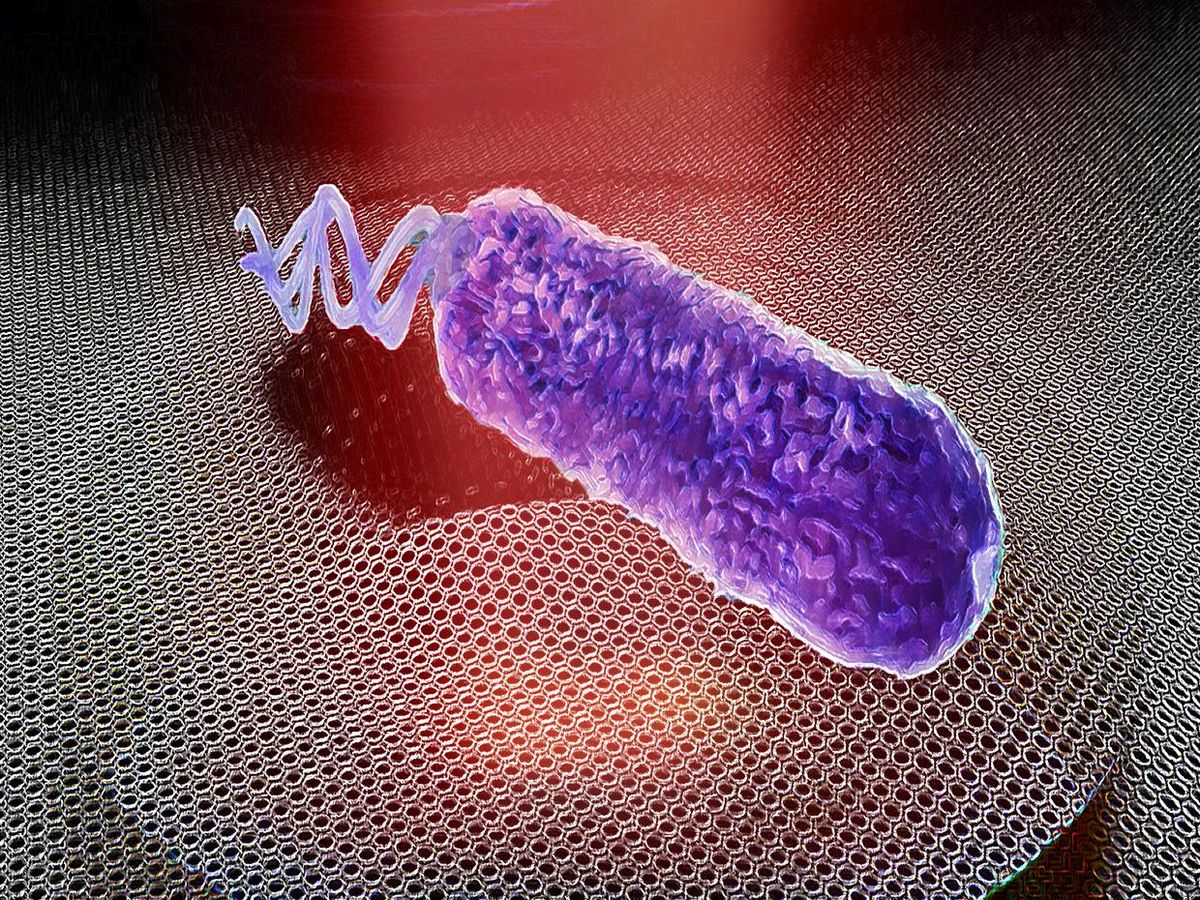

Now researchers at Delft University of Technology (TU Delft) in the Netherlands have used graphene sheets to serve as a kind of drum for detecting the movements of a single bacterium. In research published in the journal Nature Nanotechnology, the TU Delft researchers created a device that can sense an object, such as a bacterium, sticking to the surface of the graphene drum and creating oscillations with nanoscale amplitudes.

“When a single bacterium is adhered on the graphene drum, it can transduce a time-dependent deflection on the graphene that is then detected by laser light,” said Farbod Alijani, assistant professor at TU Delft and lead researcher on the project.

The researchers performed experiments in a cuvette containing live E. coli bacteria in a growth medium. In the TU Delft teams’ first measurements, they were immediately able to detect the movements of the bacteria, according to Alijani.

These movements were manifested as a noisy signal within a spectrum that was consistent with biological processes. This observation is the first time that the sound generated by a single bacterium in its aqueous growth environment could be detected, according to Alijani.

The sensor is detecting oscillations that primarily come from the motion of flagella, the tail-like structures that propel the bacterium through its environment. To get a sense of how lightly these flagella beat on the graphene drums, take the force of a boxer punching a bag and divide it by 10 billion, says Alijani.

“When a single bacterium is adhered on the graphene drum, it can transduce a time-dependent deflection on the graphene that is then detected by laser light.” —Farbod Alijani

Alijani believes that the technique’s ability to trace changes in a bacterium’s motion on the nanoscale could help in the administration of antibiotics and could make it a valuable tool in monitoring antibiotic resistance.

Antibiotic resistance is determined by monitoring the oscillations levels. Persistent oscillations indicate that the bacterium is alive and resisting the antibiotic. A decrease in oscillations would indicate that the antibiotics are killing the bacteria.

Alijani points out that while there are many semi-automated antibiotic sensitivity tests currently on the market, the bacteria need to grow, which takes time. This new test provides clear indicators of antibiotic resistance within just 1 or 2 hours as compared to current antibiotic sensitivity tests that require at least 24 to 48 hours, according to Alijani.

“Our technology stands out in terms of sensitivity and speed as it can perform antibiotic susceptibility at the single-cell level using many parallelized sensors,” said Alijani, who notes that one chip can host up to 10,000 sensors.

This graphene sensor falls into the category of a biosensor as opposed to an electronic sensor. The use of graphene in biosensors is gaining broad commercial use, while electronic sensors based on graphene remain at an early stage, with companies like U.K.-based Paragraf beginning to roll out Hall-effect sensors based on graphene.

“We are picking up vibrations optically, not electrically and the actuation of the drums is simply by the bacterium itself (no electrical actuation),” Alijani added. “It is the bacterium that vibrates the sensor.”

The graphene that the TU Delft team used is what’s known as chemical vapor deposition (CVD) bilayer graphene. CVD graphene is markedly cheaper to produce than mechanically exfoliated graphene that needs to be stripped off of graphite one atomic layer at a time in a process known as the “scotch tape” method. This makes the raw material for making the device somewhat more affordable.

While raw-material considerations are always an important factor, “the immediate next step in development is to validate the technology against a variety of bacteria and antibiotics with different modes of action,” said Alijani. “As we bring the technology closer to market, we will very soon launch a startup in collaboration with our vaporization partners.”

In these next steps, Alijani said the team will look to further optimize the readout system, as well as better understand the relation between biophysical processes of a single bacterium and the nanoscale vibrations detected.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.