Ever since researchers discovered that magnetic field sensors could be produced on organic thin-film materials, there has been the hope the discovery would lead to inexpensive sensors on flexible substrates. If you could get it right, there was huge potential simply due to the ubiquity of magnetic field sensors in consumer electronics.

There were just a couple of rather large problems. A very narrow magnetic field range limited these sensors usefulness and they required continuous calibration to compensate for changes in temperature and the degradation of the material.

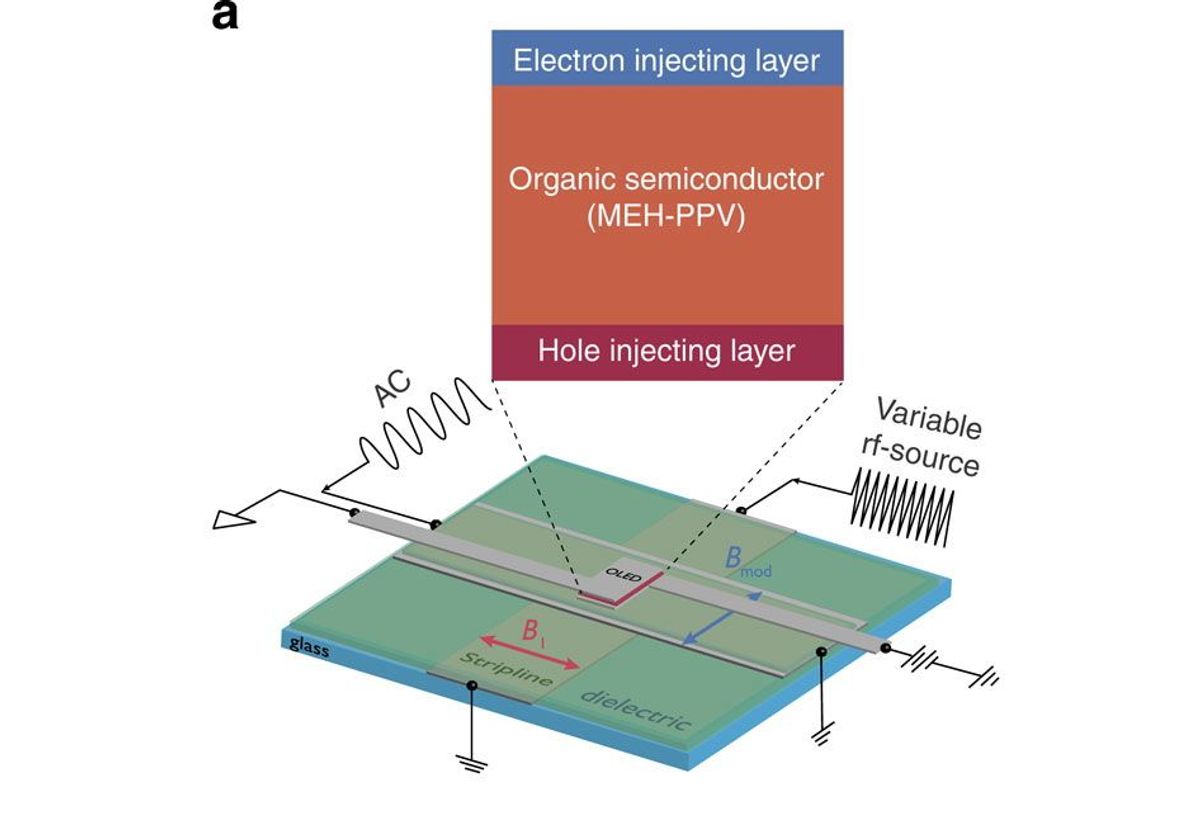

The magnetic sensing film, which is described in the June 12th edition of the journal Nature Communications, also resists heat and degradation and operates at room temperatures. The thin film is an organic semiconductor polymer called MEH-PPV.

Christoph Boehme, Associate Professor at the University of Utah, and one of the named authors of the Nature paper, describes the thin film in the Institute of Physics’ nanotechweb.org website story linked to above as an orange-colored "electrically conducting, magnetic field-sensing plastic paint that is dirt cheap. We measure magnetic fields highly accurately with a drop of plastic paint, which costs just as little as drop of regular paint."

The researchers are so enthusiastic about their discovery that they are considering launching a spinoff company to commercialize the technology. The commercial applications for magnetic-field sensors are quite broad, so let’s hope the scientists get some good business advice on which application space to target their technology. Further, they should refrain from three-year projections to having devices on the market, managing investors’ expectations is often the key to success.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.