Over the years, light has been the key to powering and directing the movement of nanomotors. But precisely controlling that movement and actuating motion lateral to a beam of light has remained a challenge.

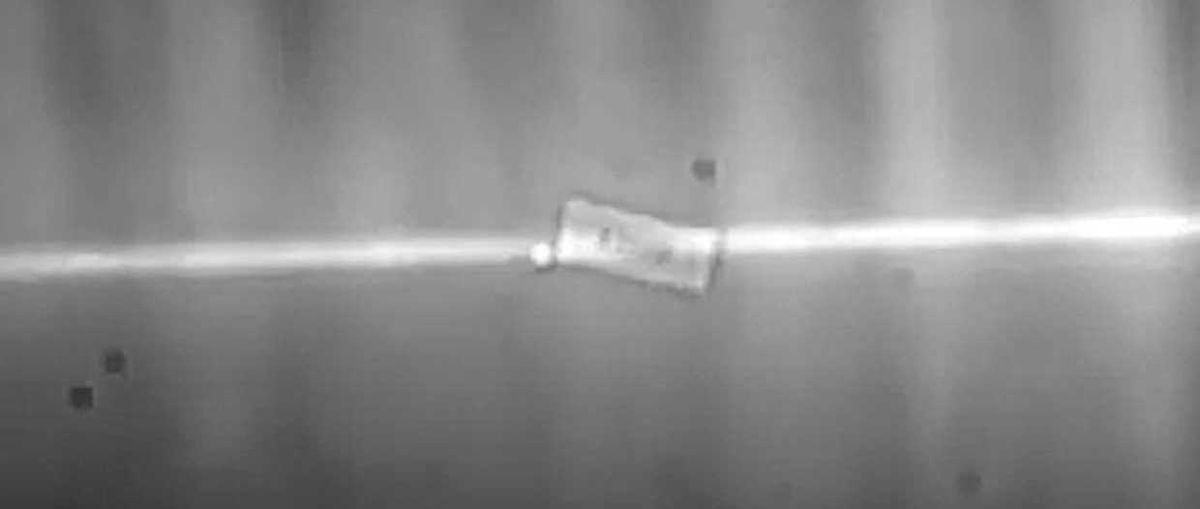

Now researchers at the Institute of Industrial Science at The University Of Tokyo are using light to drive objects with both precision and lateral motion. (See video below.)

Of course, light—like any particle—carries momentum. Which means light can transfer its momentum too, as in the work that won the 2018 Nobel Prize in physics for the development of so-called optical tweezers.

The University of Tokyo researchers rely on a technology called plasmonics—exploiting waves of electrons (a.k.a. surface plasmons) that are triggered when photons strike a metal surface.

Earlier this year, researchers from Vanderbilt University in the U.S. extended the utility of those Nobel-winning optical tweezers by using plasmonics to enable handling of delicate biomolecules.

Now the University of Tokyo research, published in the journal Science Advances, harness plasmonics to move the nanomotor in directions other than just that of the incident laser beam.

Researchers placed metal nanoparticles in strategic locations to exploit the scattering of light. This makes it possible for the laser plus nanoparticles to move objects laterally as well as along the direction the laser light is propagating.

This technique provides precise control of the optical force generated from light’s linear momentum, according to Yoshito Tanaka, an assistant professor at the University of Tokyo, and co-author of the research.

“One of the strong points of our nanomotor is fast and precise control, which is essential for lab-on-a chip applications” said Tanaka.

Moreover, Tanaka argues that the applications of this nanomotor are not limited to lab-on-a chip devices.

“By taking advantage of fast and precise control of the optical force, our nanomotor could be used for the measurement of force on protein molecular motors and their motion control,” Tanaka added.

Tanaka also believes that their research could further advance applications of light-driven nanomotors for assembling and powering nanomachines and nanorobots.

The Technology Readiness Level (TRL) of this work and most light-powered nanomotors at this time is still Level 4: validation in laboratory environment, according to Tanaka. He argues that in general the main hurdle for nanomotors to move into the industrial level is the cost of fabrication.

“The relative weakness of our approach is a more expensive fabrication of our nanomotors than others,” conceded Tanaka. “But, if our nanomotors can be fabricated by nanoimprint lithography technology, this weakness should be solved.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.