Scientists have created a new sensor that can be integrated within dental implants to passively monitor bone growth, bypassing the need for multiple x-rays of the jaw. The design is described in study published September 25 in IEEE Sensors Journal.

Currently, x-rays are used to monitor jaw health following a dental implant. Dental x-rays typically involve low doses of radiation, but people with dental implants may require more frequent x-rays to monitor their bone health following surgery. And, as professor Alireza Hassanzadeh of Shahid Beheshti University, Tehran, notes, “Too many X-rays is not good for human health.”

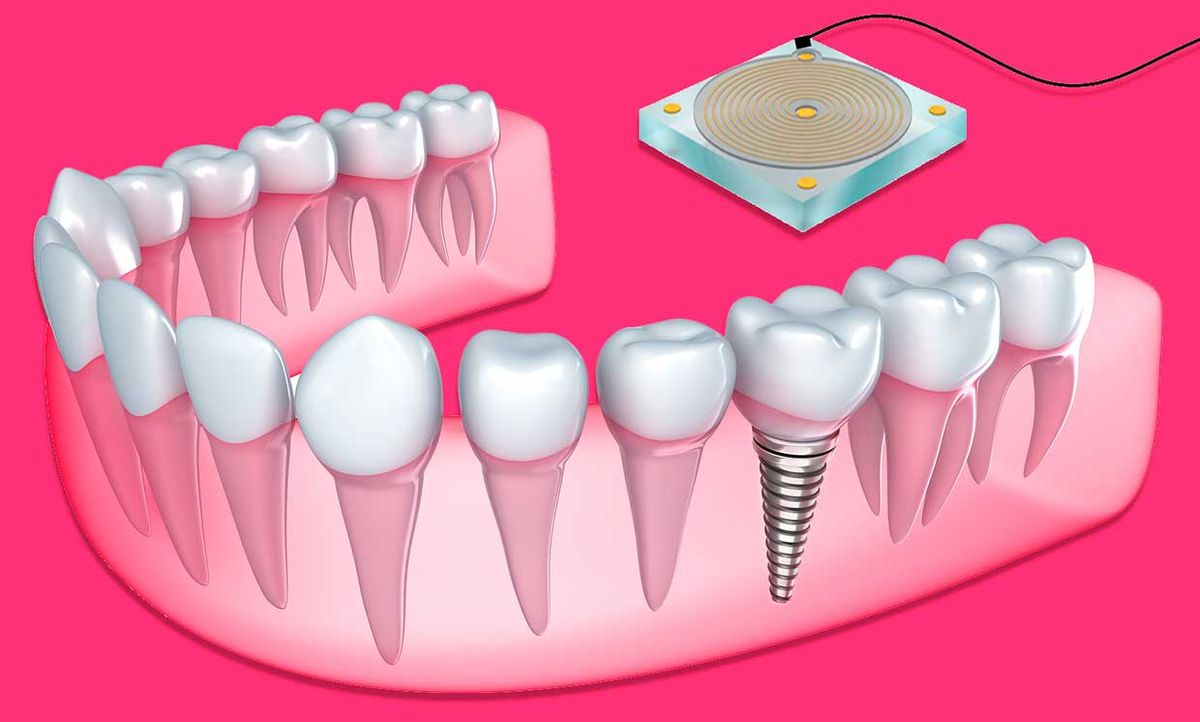

To reduce this need for x-rays, Hassanzadeh and two graduate students at Shahid Beheshti University designed a new sensor that can be integrated within dental implants. It passively measures changes in the surrounding electrical field (capacitance) to monitor bone growth. Two designs, for short- and long-term monitoring, were created.

The sensors are made of titanium and poly-ether-ether-ketone, and are integrated directly into a dental implant using microfabrication methods. The designs do not require any battery, and passively monitor changes in capacitance once the dental implant is in place.

“When the bone is forming around the sensor, the capacitance of the sensor changes,” explains Hassanzadeh. This indicates how the surrounding bone growth changes over time. The changes in capacitance, and thus bone growth, are then conveyed to a reader device that transfers the measurements into a data logger.

In their study, the researchers tested the sensors in the femur and jaw bone of a cow. “The results reveal that the amount of bone around the implant has a direct effect on the capacitance value of the sensor,” says Hassanzadeh.

He says that the sensor still needs to be optimized for size and different implant shapes, and clinical experiments will need to be completed with different kinds of dental implant patients. “We plan to commercialize the device after some clinical tests and approval from FDA and authorities,” says Hassanzadeh.

Michelle Hampson is a freelance writer based in Halifax. She frequently contributes to Spectrum's Journal Watch coverage, which highlights newsworthy studies published in IEEE journals.