THE INSTITUTE The startup StartChange.Today, cofounded by IEEE Member Aisha Nazia Nasir Mayin in Bangalore, India, has developed a chatbot in association with the marketing agency Chatveda to help users access whether they are at risk of catching the coronavirus by answering a few simple questions.

Mayin is an active IEEE volunteer. She’s the content marketing chair for the IEEE Technology and Engineering Management Society. She also serves as vice chair for the society’s IEEE Women in Engineering activities, in India.

The Institute asked Mayin about the chatbot.

This interview has been edited and condensed for clarity.

What problem are you trying to solve?

As the number of people with COVID-19 continues to increase, it’s natural to worry about whether you might be infected.

We wanted to develop a platform to make it easy for people to assess themselves and get immediate results so they could take precautions. We also wanted to help alleviate stress on the health care system and remove panic about catching the virus.

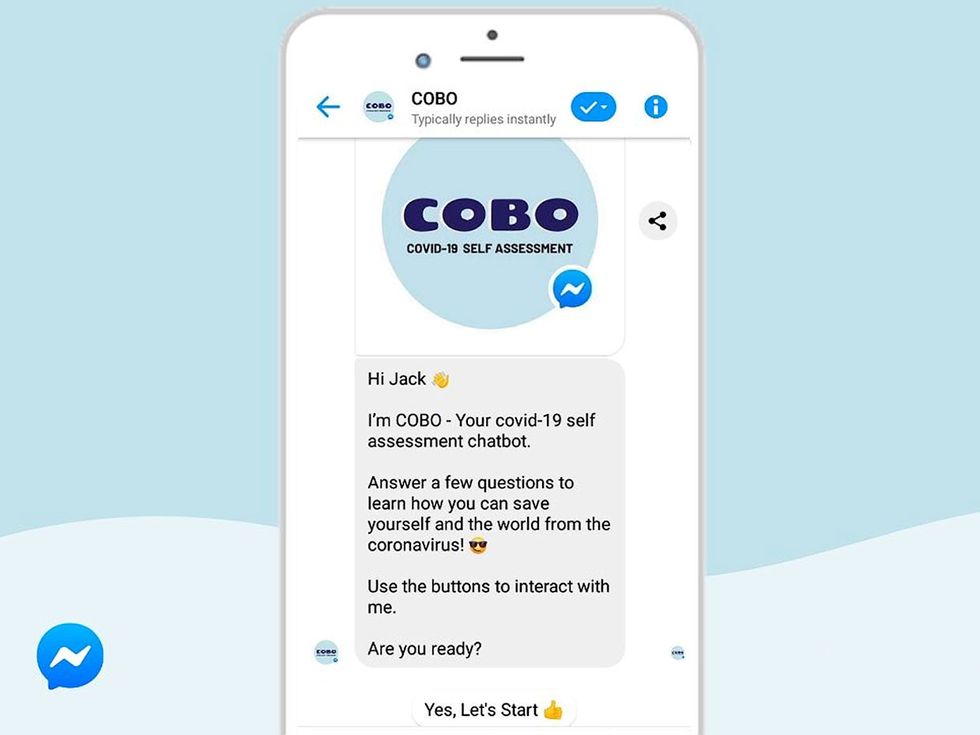

We came up with COBO, a COVID-19 self-assessment Facebook Messenger chatbot.

What technologies are you using?

Facebook Messenger, which is one of the most popular messaging apps in the world. It has more than 1.4 billion users, and is expected to grow to 2.4 billion users by 2021. With an open rate of more than 90 percent, Messenger chatbots are the best platform to communicate with a large audience at scale.

Explain how your project works.

The self-assessment test will enable anyone to answer a few questions to check whether the person might be at risk of being affected by the COVID-19 coronavirus.

Our chatbot wasn’t made to give people medical results. But based on the information from the users, we can help people understand what they are supposed to do if they are in a high-risk environment.

In an accessible, conversational format, the test requests information such as the user’s age, postal code, travel history, symptoms and their severity, and chronic health conditions. Based on the responses, the bot will recommend a course of action such as consult with your doctor, self-quarantine, or go to the hospital.

How are you protecting people’s privacy?

Team StartChange.Today and Chatveda won’t use the data collected by the chatbot for any personal or commercial use. Data such as travel history and existing health conditions will be shared only with a group of doctors and government officials for the sole use of providing better health care and increasing the efficiency of the health care system.

What challenges have you faced, and how did you overcome them?

Initially, it was definitely a challenge for the team to work remotely, but we got through it by finding new ways to collaborate. Also, converting medical scenarios into a form that is easily relatable to the average person and understanding and figuring out the probabilities and permutations behind the bot’s algorithm based on the user’s input was also quite a challenge. But we worked with doctors who were proactive and helpful.

What is the potential impact of the technology?

The bot will benefit the general public by offering them a quick self-assessment test. Also, by aggregating the medical data the bot collects, the doctors can focus their efforts on those who are at high risk for catching the virus.

In the beta version, we are focusing on segmenting the audience based on the various factors such as travel history, and their health conditions and the severity. This helps the doctors focus on attending to people who need immediate care. This also helps in directing people who don’t require a doctor to help lines set up to assist those with COVID-19 questions. This will help officials manage the rush of those seeking medical care and reduce the high number of walk-ins to hospitals by those who suspect they have the virus.

In the near future, the chatbot will also provide medical authorities and decision-makers with a map based on postal codes, which could help them see where outbreaks are occurring and take action to contain them.

How close are you to the final product?

We have developed a prototype of the bot, which was launched in April. We are working with several doctors trained to treat COVID-19 patients to make sure the people who fall in the risk category based on the medical protocols provided by the doctors and government authorities get immediate medical attention.

How many people are involved, and how many IEEE members are involved?

I’m the only IEEE member of our team of five. The others are the three founding partners of Chatveda—Abid Omar, head of bots; Teesha Thomas, director of content; and Nikesh Ghosh, head of operations. Dr. Athul Joseph Manual provides medical expertise.

How can other IEEE members get involved?

They should take the self-assessment test and provide feedback about how we can enhance the experience. For those who want to help us improve the bot—including developers, doctors, data analysts, and data scientists—they can send me an email and put “COBO” in the subject line.

Attention IEEE members: Are you part of a team responding to the COVID-19 crisis? We want to hear from you! Wherever you are and whatever you are doing, if you are helping to deal with the outbreak in some way, let us know. Send us accounts of anywhere from 200 to 800 words, or simply give us a rough idea of what you are doing and your contact information. Write to k.pretz@ieee.org