Lasers have been used inside microscopes for many years to trap and move objects floating around in solution.

Now Linhan Lin, a postdoctoral researcher in Yuebing Zheng’s group at the University of Texas in Austin and colleagues have developed a new strategy for drawing those particles down to the surface, where they can be arranged at will.

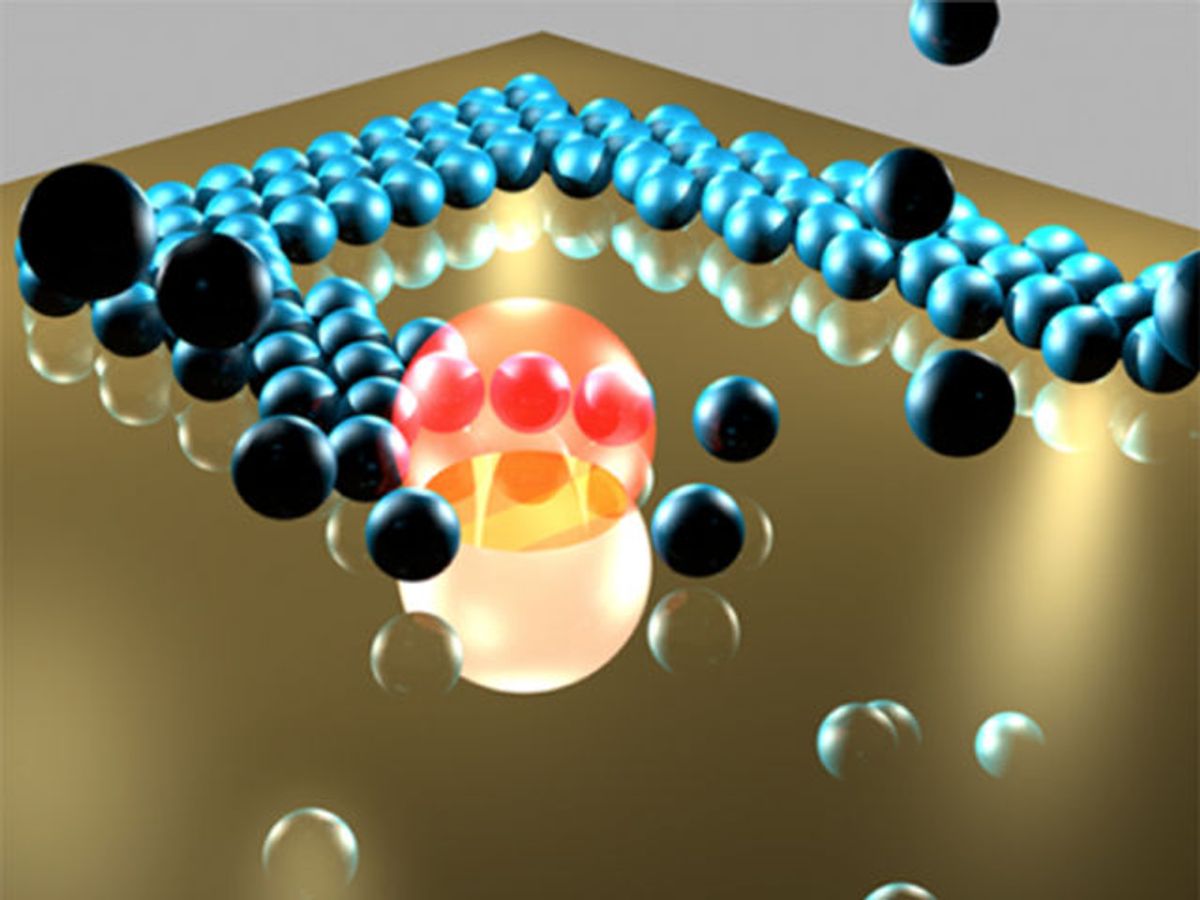

The technique, which team members have dubbed bubble-pen lithography, uses a laser to excite a special layer of material applied to a glass slide. The resulting hot spot vaporizes solution above it, creating a temporary microbubble. Convective flow around this bubble draws nearby particles to the surface, where heat and short-range attraction can then help the particles stick.

The process, which was described in the January issue of Nano Letters, was used to pattern microscopic colloidal particles as well as 6-nanometer-wide quantum dots. And it seems surprisingly quick. Here’s a real-time video of the patterning of the requisite Texas Longhorn from 300-micrometer-wide polystyrene spheres in solution.

This is not the first time that light has been used to pattern particles suspended in solution. In 2009, for example, a group based in California demonstrated a “NanoPen” that used electrodes and low-intensity light to pattern nanoparticles placed in a conductive solution.

Since the bubble-pen approach does not require a conductive solution, Zheng says it should be more flexible. The technique does still need to have a specialized substrate to work, though. In order to create vapor bubbles with a laser intensity that won’t damage particles, the team enhances the laser’s effect through the use of a plasmonic substance—in this case, gold nanoislands. Other materials can be placed on top of this layer; among the demonstrations in the paper is the patterning of particles on a layer of molybdenum disulfide.

The team hopes to use the bubble-pen technique to pattern both inorganic particles, such as quantum dots, as well as organic materials for biological applications, such as sensor arrays. They’re investigating whether the technology could be used in a speedy, low-cost roll-to-roll process.

Particle size—particularly when it comes to nanometer-scale particles like quantum dots—could be an obstacle to high-throughput work, says Lih Lin, a professor of electrical engineering at the University of Washington in Seattle who has also done prior solution-based optical nanolithography work.

The smaller the particle, the less of it there will be to fall under the influence of the trapping mechanism. The odds of trapping a particle can be increased by upping the concentration of particles, Lin says, but then the probability of trapping more than one particle at a time will increase as well, which could limit applications.

Zheng agrees it’s an issue. He says the team aims to mitigate the problem by using multiple beams (manipulated with a digital device) to boost throughput. The team says it should be possible for more than 100 beams to pattern in parallel.

Rachel Courtland, an unabashed astronomy aficionado, is a former senior associate editor at Spectrum. She now works in the editorial department at Nature. At Spectrum, she wrote about a variety of engineering efforts, including the quest for energy-producing fusion at the National Ignition Facility and the hunt for dark matter using an ultraquiet radio receiver. In 2014, she received a Neal Award for her feature on shrinking transistors and how the semiconductor industry talks about the challenge.