Hydrogen gas generated using renewable energy is a promising source of clean fuel. One of the most common existing technologies for electrolysis—the process of generating hydrogen gas from water using electricity—is proton exchange membrane (PEM) electrolysis. Governments and organizations like the International Renewable Energy Agency are pushing for initiatives to make hydrogen more mainstream, but PEM electrolysis depends on the rare and expensive catalyst iridium, which has been a bottleneck for the tech’s adoption.

Recently, the materials science startup Mattiq synthesized hundreds of possible replacements for iridium. The company’s method of testing these new materials is significantly faster than those of traditional lab experiments, and could pave the way to finding a more accessible replacement for iridium in PEM electrolyzers, thus making adoption more widespread.

“If you think about the periodic table, with over a hundred unique elements, you can mix them in so many different ways.” —Andrey Ivankin, Mattiq

Currently, PEM electrolysis is reliant on iridium to catalyze the reaction that generates oxygen from water, a key part of electrolysis. Iridium works well as a catalyst because it hits the reactiveness sweet spot—it’s active enough to spur the electrolysis reaction, but not so active it would quickly degrade in the acidic environment of PEM electrolyzers, says Andrey Ivankin, Mattiq’s chief technology officer.

Iridium’s biggest downsides are its scarcity and difficulty to obtain; only 7,000 kilograms are produced each year. It is found in platinum ores but is one-tenth as abundant as the platinum in those ores. Small amounts are also retrieved as a by-product of mining other metals. The International Renewable Energy Agency estimates that the demand capacity for hydrogen electrolyzers will reach 100 gigawatts by 2030, but the current annual production of iridium can support only up to 7.5 GW of capacity.

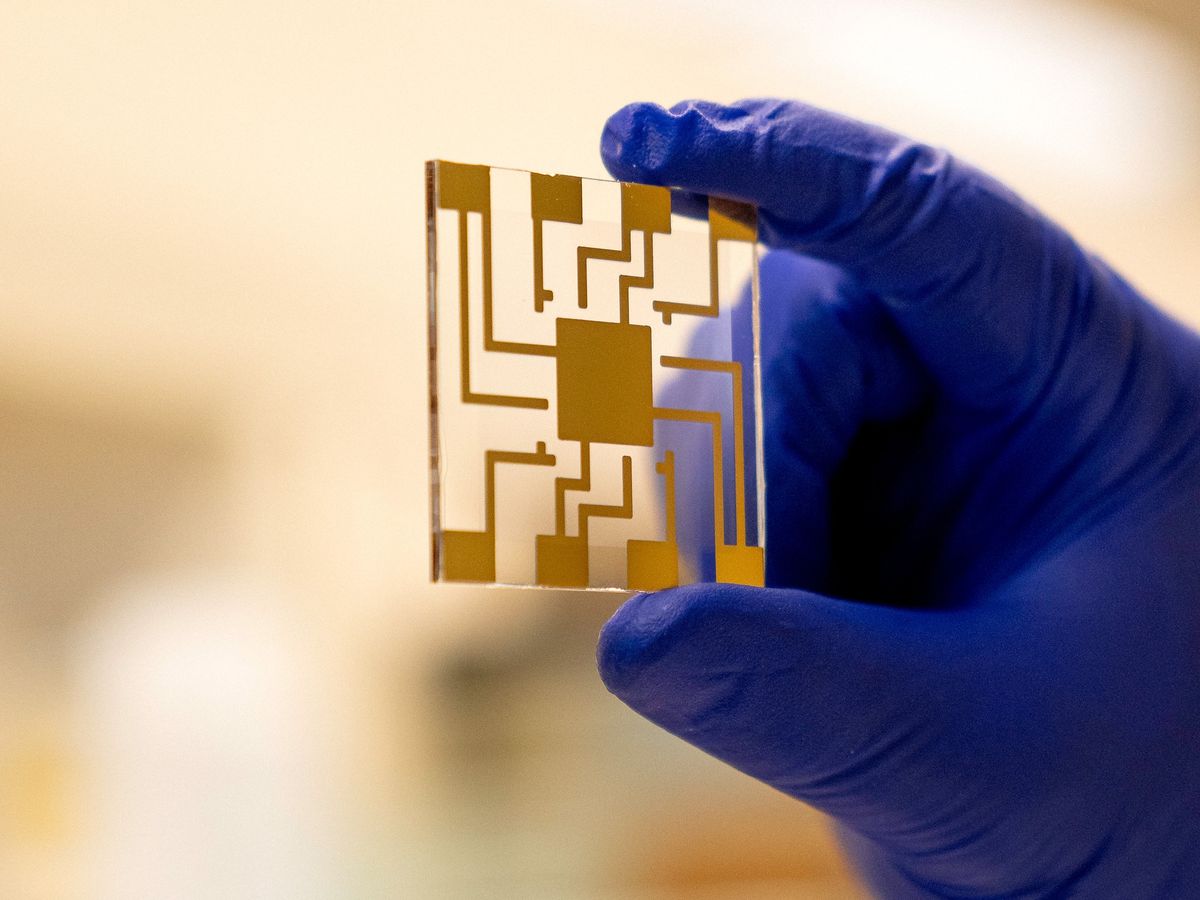

Mattiq is a startup from Northwestern University in Evanston, Ill., specializing in materials discovery for sustainable technologies. The company tackled the challenge of finding a suitable iridium replacement for PEM electrolysis as a proof of concept for its high-throughput materials discovery platform. Mattiq’s discovery process uses microchips built using nanotechnology to test a large number of potential new materials all at once; each chip can contain 10,000 nanoscale reactors that each hold materials of different compositions. Being able to test a vast number of materials concurrently is an important aspect of successful materials discovery, as there are a near limitless number of compositions to try when creating a new material, Ivankin says.

“If you think about the periodic table, with over a hundred unique elements, you can mix them in so many different ways,” Ivankin says, especially when considering variables like material size and structure.

Mattiq approached the problem of iridium scarcity by seeking materials that fulfilled three criteria: They had to react as well as or better than iridium, be as durable or better, and be more abundant. The company used machine learning to suggest new compositions to try, which were then created and deposited alongside other new material compositions on a chip. The entire chip underwent testing in an environment that mimicked a PEM electrolyzer. Voltages were applied to the chip to create outgoing currents in each material in order to indicate reactivity. Afterward, results were fed back into the machine-learning algorithm to start the process over again.

By systematically changing the ratio and ingredients in each sample and feeding the results back into the machine-learning algorithm, the Mattiq platform was able to iterate toward more promising compositions. Each nanochip could hold 10,000 compositions, and researchers could run through 10 chips every day. In just six weeks, the platform was able to test 6 million compositions and yielded hundreds of promising new materials for further testing as replacements for iridium.

Some of the new materials include transition metals, which are much more abundant and easier to obtain than iridium, while other promising candidates still contain iridium but as part of a different structure that makes the entire material more reactive than pure iridium.

“If you can, let’s say, increase its activity [by a factor of 10], in a way you now need 10 times less iridium,” Ivankin says.

The company is currently using more traditional methods of experimentation to test all the promising new candidates by synthesizing each material on the scale of a gram or so, and in actual electrolyzers. Mattiq is also in the early stages of partnering with other companies interested in using iridium replacements for commercial applications.