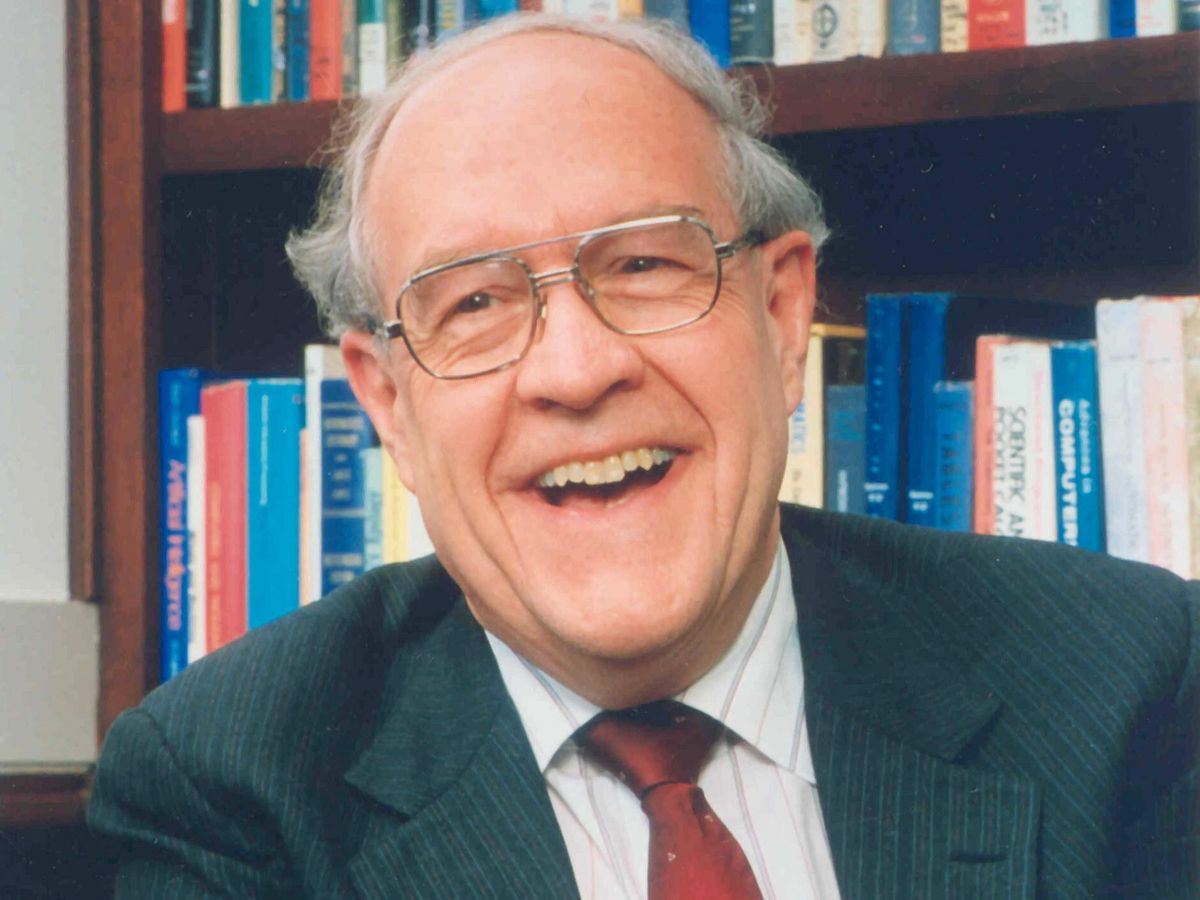

Frederick P. Brooks Jr., a prolific computer scientist and longtime professor of computer science, died on 17 November at the age of 91.

While working as a project manager at IBM in the 1960s, the IEEE Life Fellow led the development of the System/360 computer family. It was the first vertically compatible family of mainframe computers. Brooks also developed IBM’s OS/360, the world’s largest software project at the time. He is credited with coining the term computer architecture, which is used to describe how hardware and software are organized to make up a computer system and the operations which guide its function. He wrote The Mythical Man-Month, a book of essays published in 1975 that detailed lessons he learned from challenges he faced while developing the OS/360.

Brooks left IBM in 1964 to found the University of North Carolina’s computer science department in Chapel Hill.

Although he retired from teaching in 2013, Brooks was still active in the university’s research program in virtual environmentsand scientific visualization until 2020.

Breakthroughs at IBM

After earning a bachelor’s degree in physics in 1953 from Duke University, in Durham, N.C., Brooks received a Ph.D. in applied mathematics in 1956 from Harvard. He completed his dissertation—the development of a computer that could do payrolls—under the supervision of computer pioneer Howard Aiken, who had designed IBM’s Harvard Mark I computer.

Brooks joined IBM in Poughkeepsie, N.Y., in 1957. His first assignment was working on the IBM 7030. Known as Stretch, it was the first transistorized supercomputer. Although commercially unsuccessful, Stretch inspired technologies used in inventions such as instruction pipelining and memory interleaving. Brooks also designed Harvest, IBM’s 7030 character-processing auxiliary processor.

His next project was the IBM 8000 series of computers. In 1961 IBM deemed the project a failure and terminated it.

That same year, Brooks was tasked with leading the development of a family of general-purpose systems for both commercial and scientific applications. Before the release of IBM System/360, computer systems were incompatible with each other, even if they were developed by the same manufacturer. Software and peripherals from old systems would not work with new ones, making it costly for customers to upgrade their hardware, according to an IBM article about the technology.

The System/360, released in 1964, contained six processor models with 40 peripherals. The line was named the 360 because it addressed the needs of all types of customers. Within five years of its release, more than 3,000 units were sold, and it generated more than US $100 billion in revenue through the mid-1980s, according to the IBM article.

The system also popularized the concept of a computer upgrade and introduced the industry standard of the 8-bit byte, for which Brooks was responsible. The 8-bit byte enabled a computer to run software that produced both upper- and lower-case characters.

Due to the success of the system, Brooks was appointed lead developer of the 360 family of operating systems. The OS/360 was the forerunner of Microsoft’s Windows, Apple’s iOS, and Google’s Android software systems.

When Brooks joined the University of North Carolina, he was its first professor of computer science. He served as department chair for 20 years, and he taught and conducted research at the university for more than 50 years. His research focused mainly on interactive computer graphics and virtual reality.

“Many in the department and beyond appreciated the fact that in a world full of academic competition and research silos, Brooks fostered a departmental culture of open collaboration and respect,” says Mary C. Whitton, a retired University of North Carolina research professor. The IEEE life senior member worked closely with Brooks for more than two decades.

The Turing Award and the National Medal of Technology

Brooks was honored multiple times for his pioneering work. He was awarded the 1993 IEEE John von Neumann Medal and received two awards from the IEEE Computer Society: the 1980 Women of ENIAC Computer Pioneer Award and the 1970 W. Wallace McDowell Award.

He received the 1999 A.M. Turing Award from the Association for Computing Machinery, known as the Nobel Prize of computing. He was honored for “landmark contributions to computer architecture, operating systems, and software engineering.”

Brooks also received the 1985 U.S. National Medal of Technology alongside his IBM colleagues Bob Evans and Erich Bloch for the development of System/360. The award was given to them by U.S. President Ronald Reagan.

Joanna Goodrich is the associate editor of The Institute, covering the work and accomplishments of IEEE members and IEEE and technology-related events. She has a master's degree in health communications from Rutgers University, in New Brunswick, N.J.