A powerful flame retardant added to lithium-ion batteries that only gets released when the devices get too hot could help keep them from catching on fire, a new study finds.

When lithium-ion batteries overheat, they can burn through clothing, burst into flames and even explode. Such "thermal runaways" have led some engineers to explore the creation of lithium-ion batteries with their own fire alarms or chemical additives that can prevent short circuits.

Researchers previously tried adding flame retardants directly into the batteries’ electrolytes, which connect the electrodes of the energy storage devices. However, these approaches significantly reduced battery performance.

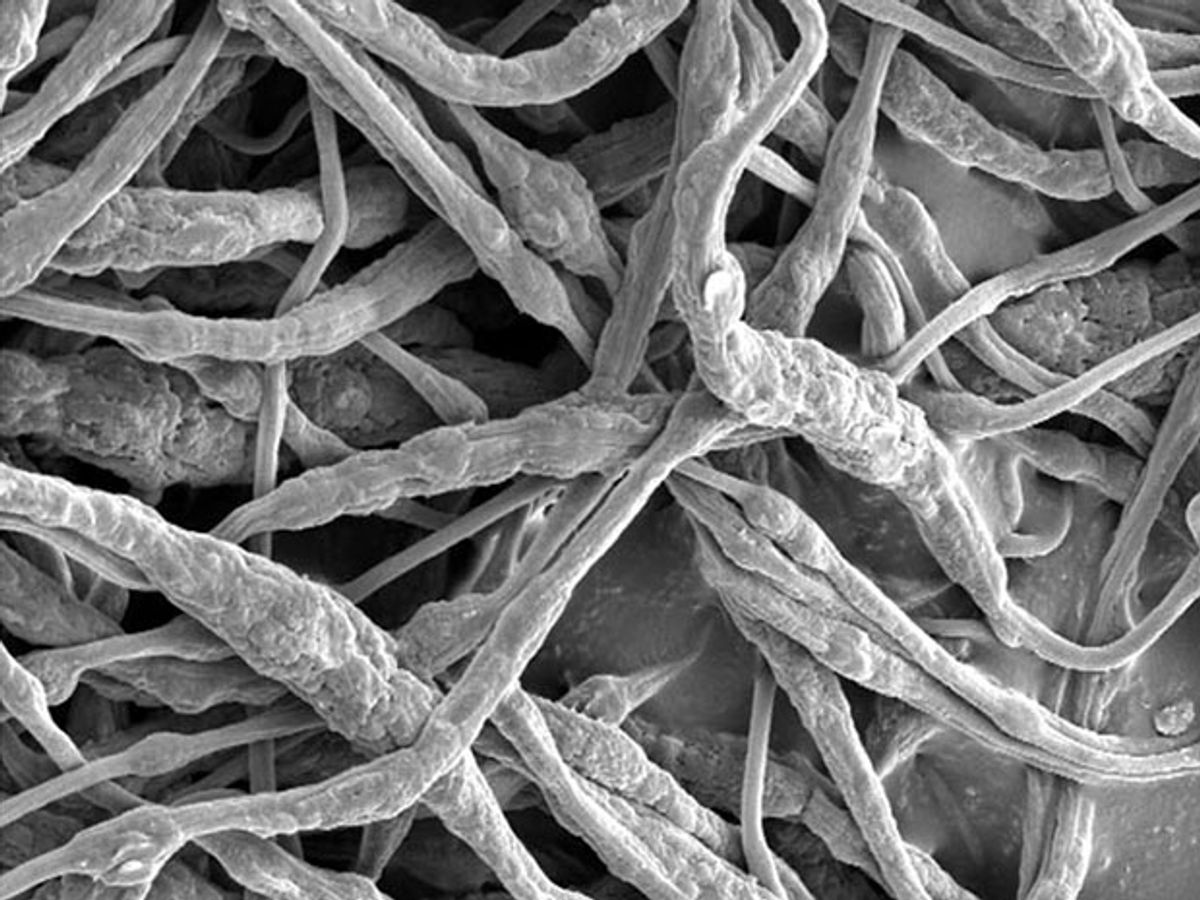

Now researchers have designed a lithium-ion battery in which the separator, the component that keeps the battery's positive and negative electrodes apart, contains a cheap, powerful, and commonly used flame retardant known as triphenyl phosphate.

During normal battery operation, the flame retardant stays encapsulated within plastic fibers. If the separator gets hotter than 150 degrees C, the plastic melts, releasing the flame retardant. In experiments, the chemical completely quenched flaming electrolyte in 0.4 seconds. The scientists detailed their findings online in the 13 January edition of the journal Science Advances.

“Using our ‘smart’ separators, battery electrochemical performance will not be affected by the flame retardant under normal conditions," says study senior author Yi Cui, a materials scientist at Stanford University in California. “However, once there is a potential thermal runaway, the flame retardant will be activated and nip the fire or explosion in the bud.”

Future research can explore how well this separator responds to electrical abuse such as overcharging or discharging too deeply, or physical abuse such as crushing or penetration, Cui says. “We believe our safe separator should find broad applications, considering that more and more fires and explosions of lithium-ion batteries have been reported recently.”

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.