A fundamental, unproven assumption in the field of DNA nanotechnology was that the nanoscale objects produced through DNA self-assembly achieved atomically precise positional accuracy.

Researchers at Technische Universitaet Muenchen (TUM), led by Hendrik Dietz, have challenged that assumption head on and built a 3-D object using DNA self assembly techniques and found that indeed the object met its design specifications down to the sub-nanometer scale.

For years now, research has shown that DNA could be programmed to take the shape of pre-determined objects. If a five-pointed star was desired, it was possible to program the DNA so that it took a shape that resembled very closely the original design. But no one really knew if the final objects met the original designs at the atomic scale.

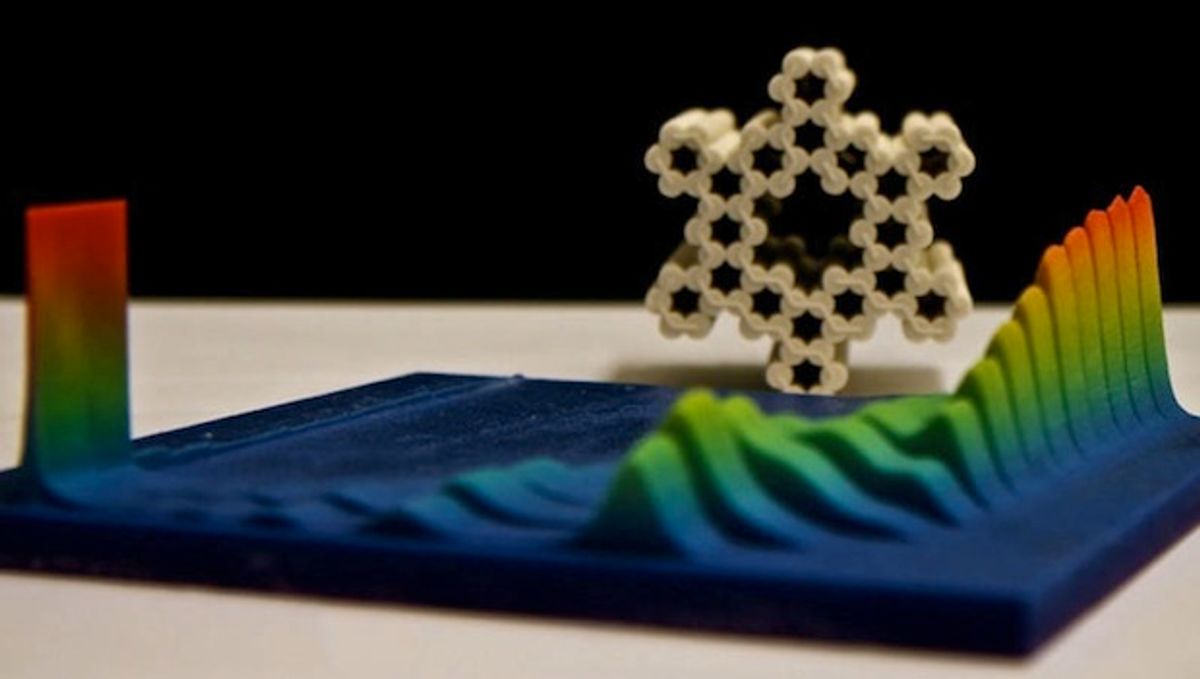

To prove this assumption, the TUM researchers designed a test object that was suitable for low-temperature electron microscopy. This object allowed for an electron density map to be generated of the object in which the resolution of the map was sufficient for a pseudo-atomic model that could be flexibly fitted to the entire object. The object, which was comprised of 460 000 atoms, incorporated a variety of designs that should make it useful in further study in the field.

A video describing the object and its model can be seen below along with further information about the research, which was published in the journal Proceedings of the National Academy of Sciences:

Finally having proof of the atomic precision of the DNA manufactured objects is a huge confirmation for the hopes of bottom-up manufacturing.

The researchers were able to achieve still another breakthrough. In a separate set of experiments, which were published in the journal Science (“Rapid Folding of DNA into Nanoscale Shapes at Constant Temperature”), they demonstrated a rapid method for folding DNA into 3D objects. The method folds DNA in within mere minutes as opposed to the typical days or week. Not only was the process fast but it also had nearly 100-percent yield.

"Seeing this combination of rapid folding and high yield," Dietz says in a TUM press release, "we have a stronger sense than ever that DNA nanotechnology could lead to a new kind of manufacturing, with a commercial, even industrial future."

The field of atomically precise manufacturing—or molecular manufacturing—has taken a big step towards realizing its promise with this latest research. We may still be a long way from realizing the “nanotech rapture” but certainly knowing that the objects built meet their design specifications and can be produced in minutes rather than weeks has to be recognized as a significant development.

Image: Dietz Lab, TUM

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.