Off a dock in the Port of Los Angeles, a 100-foot blue barge carrying large metal cages and tanks, electronic equipment, and a jumble of pipes and wires has been floating since mid-April. The dock belongs to the ocean research institute AltaSea and the barge to Equatic, which is testing a daring new idea to remove carbon dioxide from the atmosphere—by sucking it out of the seas.

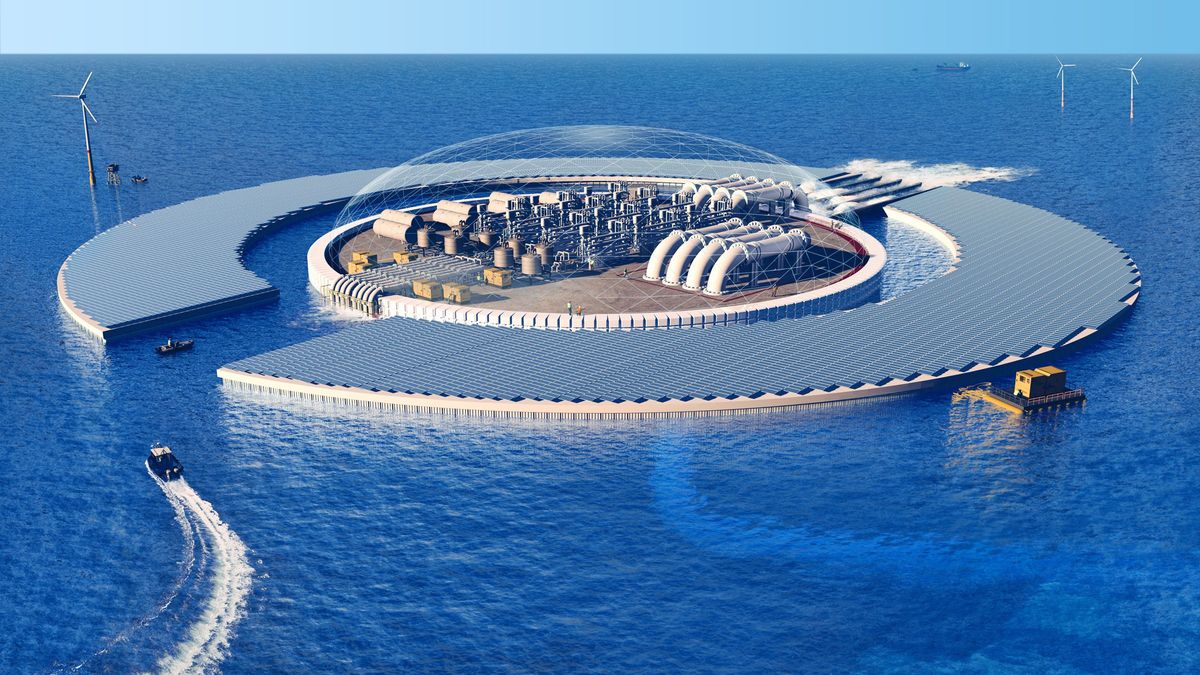

The oceans are a vast carbon sponge, absorbing a quarter of global CO2 emissions. Removing the gas makes room for them to soak up more. Equatic’s L.A. facility and another similar one in Singapore remove 100 kilograms of CO2 from seawater daily. The company plans to have a 10-tonne-per-day unit running by 2025 in Singapore, and by 2028, expects to remove millions of tonnes of CO2 annually.

Equatic’s pilot won’t be alone for long. By early fall, startup Captura will start operating a 100-tonne-per-year land-based plant also at AltaSea. Captura has been testing a smaller 1-tonne-per-year system in Newport Beach, Calif., since August 2022, and was one of 15 milestone winners announced last spring by the XPrize Carbon Removal competition, one of only three with ocean-based carbon-removal platforms.

Carbon in ocean water is present at a concentration 150 times as high as in the atmosphere.

The idea of pulling CO2 from air has only recently become mainstream. About two dozen direct-air capture projects are underway around the world, and last week the Biden administration announced the first winners of its US $3.5 billion purse for the technology. Yet carbon removal remains contentious, with a U.N. panel recently calling the approach “unproven.”

Compared to air capture, direct ocean capture (DOC) is even less charted territory. But Equatic, Captura and others are trying to prove the concept’s viability with backing from the Chan Zuckerberg Initiative, Gates Foundation, oil and gas companies, and the Advanced Research Projects Agency–Energy (ARPA-E). Pulling carbon out from ocean water, where it is present at a concentration 150 times as high as in the atmosphere, is more efficient than air capture, says Captura’s CEO Steve Oldham. DOC also avoids using precious land, could be coupled with offshore wind energy, and allows easier access to oceanic CO2 storage sites.

Both companies say they could remove carbon from oceans for around $100 per tonne, the U.S. Department of Energy’s target for its carbon-negative moonshot initiative. “Our process simply uses the ocean as a conduit for carbon removal,” says Oldham. “Combining nature and technology is very powerful. It adds scalability and gives a path to low cost.”

How Does Direct Ocean Capture Work?

Captura’s process works like a large desalination plant. It continually draws in seawater, separating 1 percent of it for conversion to concentrated brine, which the company puts through a proprietary electrodialysis machine. Electrodialysis, a process used in several industries including desalination, sends water through a series of electrified membranes (using renewable energy in Captura’s case). Each membrane separates different molecules from the water, which form acid and alkali solutions. The acid goes into the remaining ocean water, where it triggers a reaction with bicarbonate ions, causing CO2 to bubble out. Then the company adds the alkali back to the water to neutralize it before release.

“Our membranes, coatings, and stack design give a 7-to-10 times improvement on state-of-the-art electrodialysis today, which enables the economics,” says Oldham, who was CEO of direct-air capture firm Carbon Engineering before joining Captura in 2022.

Direct-air capture typically relies on large fans that blow air over expensive CO2-soaking materials. DOC has a huge inherent advantage over that, he says: the ocean, a giant natural absorber. “We don’t have to build machines that touch the air, there are no absorbents, and no by-products to get rid of.” Besides the expense of water filtration, the energy used for pumping and electrodialysis is the biggest cost, he adds, but it’s still much less than existing air-capture technologies.

Meanwhile, at MIT, chemical engineering professor T. Alan Hatton, mechanical engineering professor Kripa Varanasi, and their colleagues have devised a DOC technology that minimizes the use of membranes, making it even simpler and cheaper than electrodialysis.

The “reactive flow” system sends water through two electrochemical cells in tandem. In the first cell, a bismuth electrode releases protons that separates CO2 from the carbonates and bicarbonates in the water, while a silver chloride electrode releases chloride ions to balance charge. A vacuum chamber draws out the CO2 bubbles from the water as it passes into the second cell, where the reactions are reversed before the water is released into the ocean.

The MIT technology has also captured the ARPA-E’s attention and funds. Varanasi says they are now looking at other potentially more efficient electrode materials, and are working on a lower-energy alternative to vacuum removal for pulling out CO2. “Fundamentally nothing should stop us from scaling. We could also deploy our system at desalination plants and on ships that already have pumps and other infrastructure to move ocean water to reduce cost.”

Cost and scalability are front and center in Equatic’s plans for its technology, says CEO Edward Sanders. The startup uses a simple electrochemical process, passing electric current and bubbling atmospheric air through seawater to trigger chemical reactions that produce the mineral calcium carbonate, CO2-storing bicarbonate ions, and hydrogen gas. The acidic water is run over crushed rocks to restore its pH before discharge.

The process consumes about 2.2 megawatt-hours of energy per tonne of removed CO2. But about half that energy cost is offset by the 35 kilograms of hydrogen produced per tonne of CO2. Boeing signed a deal in June to purchase 2,100 metric tons of green hydrogen from Equatic for sustainable aviation fuel.

Scaling beyond 100,000 tonnes per year will depend on increasing electrolyzer manufacturing capability, Sanders says. Electrolyzers are usually made for pure water, and saltwater electrolysis is relatively new, he says. Equatic makes proprietary electroplated anodes that are durable in that environment.

As companies and investors move ahead with DOC projects, environmental organizations are calling for the need to be cautious. It will be important for ocean-carbon removal technologies to move forward responsibly and “not jeopardize the health of the ocean ecosystems or those who depend on them,” according to the World Resources Institute.

Mark Spalding, president of the Ocean Foundation, says that the climate crisis “is so clear and serious that we need ocean-based carbon removal.” But there are natural, proven ways to do it, such as conservation and restoration of seagrasses or kelp growth. Electrochemical DOC technologies simply have too many unknowns to spend limited research budgets on, given the limited time we have, he says. “Let’s spend on things that have greater potential for success and a lack of unintended consequences.”

The chemistry of the oceans is already changing rapidly as a result of CO2 being absorbed in the water, creating a more acidic environment. Any chemical or electrolytic process risks inadvertently affecting the local chemistry and pH of the ocean, he says. “Would it make acidification less because we are succeeding in taking CO2 out, or is something we’re doing causing some other problem? Are there any side effects? We really cannot afford mistakes.”

Sanders, Oldham, and Hatton all emphasize that their DOC technologies do not add any chemicals to ocean waters that can harm marine life. But pilot tests of the technologies will be the only way to know that they are safe.

“We retain the chemistry of the ocean water as it comes out of the plant,” says Oldham. “You will see a slight increase in pH level because we took CO2 out of ocean that creates a slightly higher alkalinity, but that is rapidly diffused in the wider ocean. We expect that within tens of meters from the outflow of the plant all ocean water will be back to its natural chemistry. We do not expect any negative environmental consequences on outflow. We have an oceanographer on staff and we are an open book.”

- Carbon Storage and Hydrogen: Match Made in Heaven? ›

- The Water Cost of Carbon Capture ›

- Future Trains Could Provide Carbon Capture on Wheels ›

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.