This Mind-Bending Actuator Could Make Robots Safer and More Energy Efficient

Wrap your head around SRI's new actuator, based on an ultra-compact infinitely variable transmission

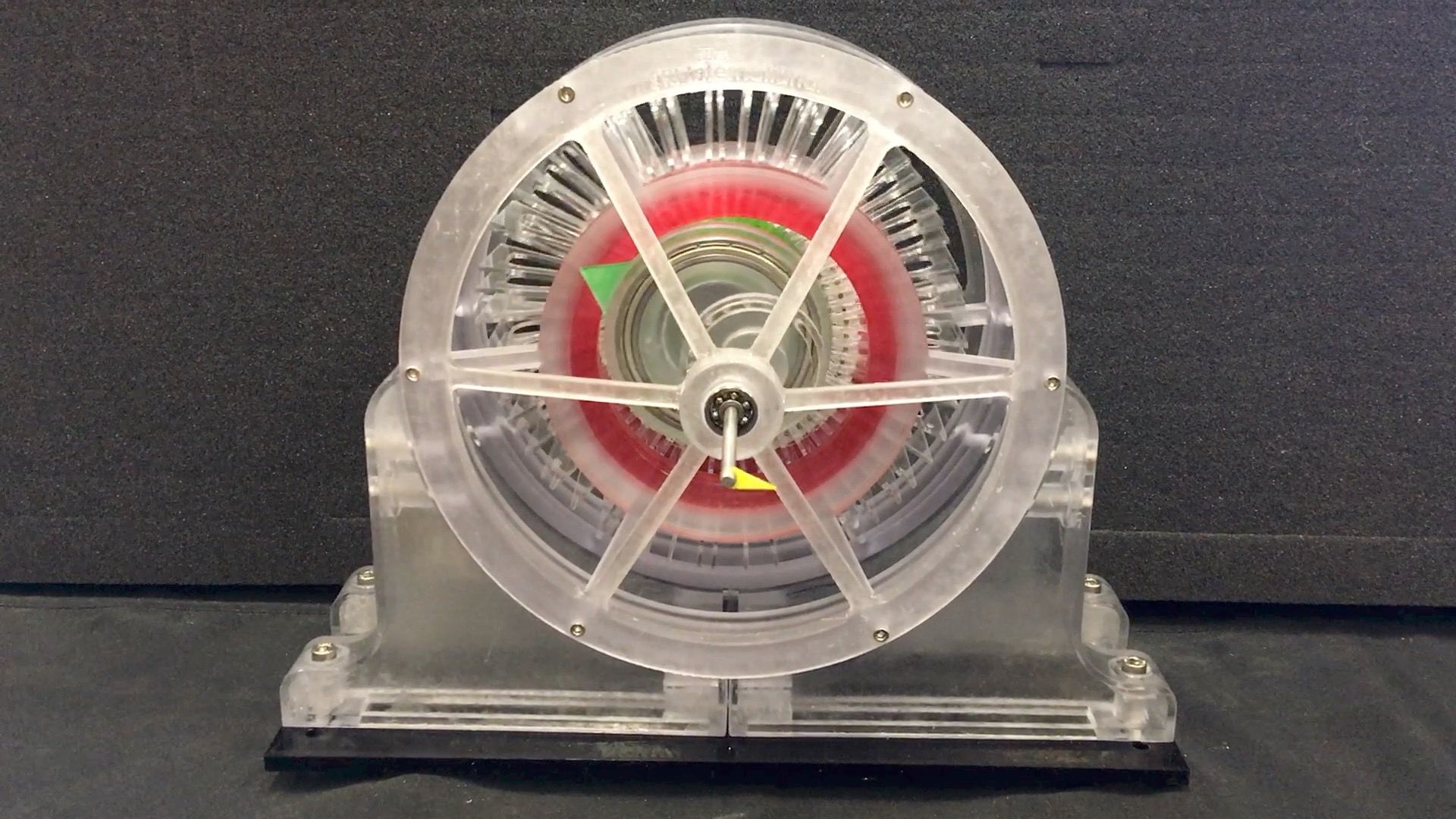

Last year, SRI’s Alexander Kernbaum introduced us to Abacus Drive, a new kind of rotary transmission based on pure rolling motion that promises to be much cheaper and much more energy efficient than harmonic gears, which are the current (and quite expensive) standard. Now Kernbaum is back with another ingenious transmission design: an ultra-compact, infinitely variable transmission based on a novel nested-pulley configuration. This new kind of actuator could make robots—and all kinds of other things—safer, more affordable, and vastly more efficient.

In an infinitely variable transmission, which is a specific kind of continuously variable transmission, the transmission ratio includes a zero point that can be approached from either a positive side or a negative side. In other words, a constant input, like an electric motor turning the same direction at the same speed, can be converted to an output that’s turning faster, turning slower, turning in the opposite direction, or not turning at all (in this “geared neutral” mode, you’d need infinite input revolutions to cause one output revolution, hence the name “infinitely variable transmission”).

If you can’t quite understand how it works from the video (and even Kernbaum admits that it’s difficult to visualize), read the explanation here: Inception Drive: A Compact, Infinitely Variable Transmission for Robotics

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.