"The real excitement for me is the possibility of creating new applications that exploit the remarkable flexibility and adhesive characteristics of graphene and devising unique experiments that can teach us more about the nanoscale properties of this amazing material," Bunch said.

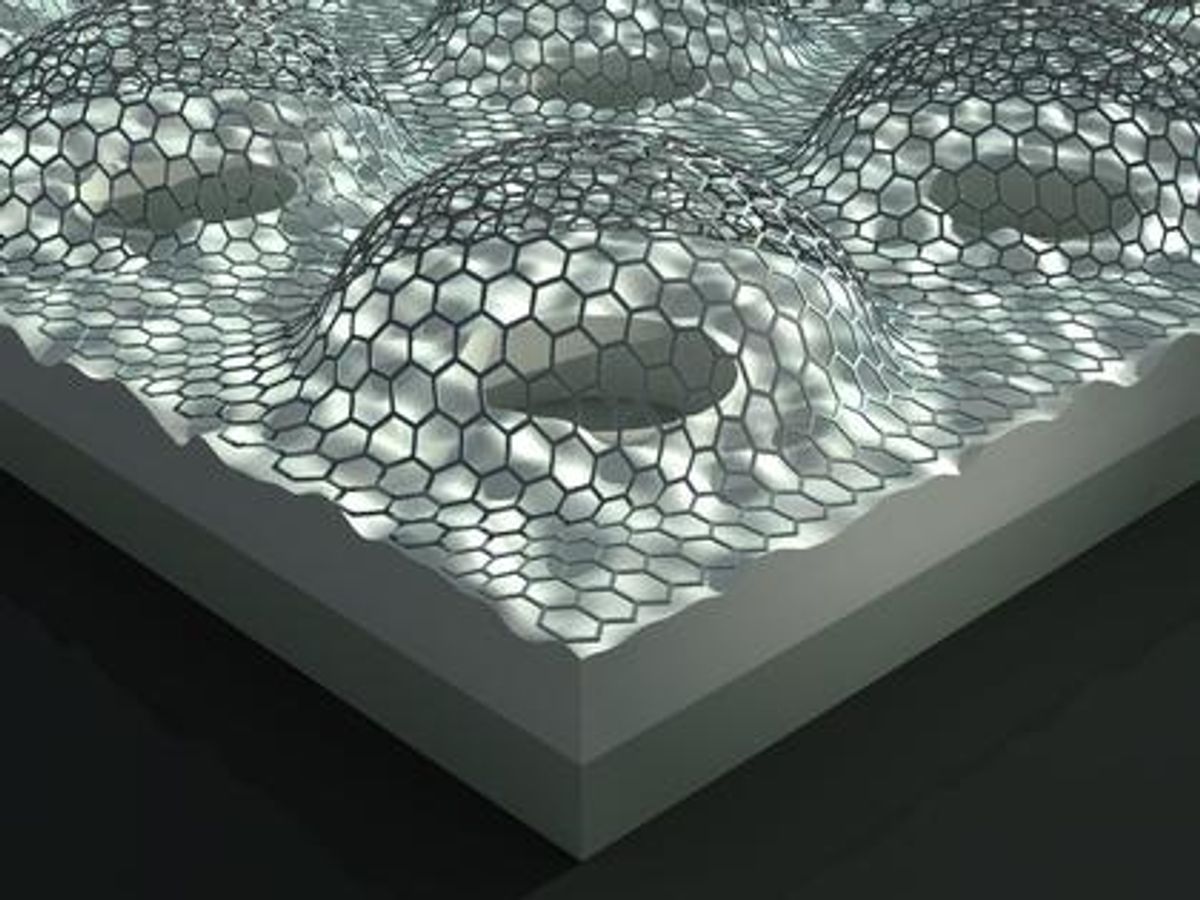

The experiment ran a so-called “blister test”—essentially, adhesion energy tests—on one to five layers of graphene after it had been placed on a glass substrate. The results showed that the adhesion energies between graphene and the glass substrate were several orders of magnitude higher than those found in typical micromechanical structures (0.45 ± 0.02 J m−2 for monolayer graphene and 0.31 ± 0.03 J m−2 for samples containing two to five graphene sheets).I understand that these adhesion properties of graphene bode well for membranes for natural gas processing or water purification, and it seems a good line of research to find uses of graphene that would seemingly avoid its inherent weakness of lacking a band gap.

It will be interesting to see what other possible applications people recognize in this new adhesion quality outside of mechanical membrane technologies.Dexter Johnson

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.

The Conversation (0)