A skeletal robotic hand with working ligaments and tendons can now be 3D-printed in one run. The creepy accomplishment was made possible by a new approach to additive manufacturing that can print both rigid and elastic materials at the same time in high resolution.

The new work is the result of a collaboration between researchers at ETH Zurich in Switzerland and a Massachusetts Institute of Technology spin-out called Inkbit, based in Medford, Mass. The group has devised a new 3D inkjet-printing technique capable of using a wider range of materials than previous devices.

In a new paper in Nature, the group has shown for the first time that the technology can be used to print complex moving devices made of multiple materials in a single print job. These include a bio-inspired robotic hand, a six-legged robot with a grabber, and a pump modeled on the heart.

“What was really exciting for us is that this technology, for the first time, allowed us to print complete functional systems that work right off the print bed,” says Thomas Buchner, a Ph.D. student at ETH Zurich and first author of the paper describing the work.

The new technique operates on principles similar to those of the kind of inkjet printer you might find in an office. Instead of colored inks, though, the printer sprays out resins that harden when exposed to ultraviolet (UV) light, and rather than just printing a single sheet, it builds up 3D objects layer by layer. It’s also capable of printing at extremely high resolution, with voxels—the 3D equivalent of pixels–just a few micrometers across.

3D Printed Robot Hand Has Working Tendonsyoutu.be

3D inkjet printers aren’t new, but the palette of materials they can use has typically been limited. That’s because each layer inevitably has imperfections, and the standard approach to dealing with this has been to scrape them off or roll them flat. This means that soft or slow-curing materials cannot be used as they will get smeared or squashed.

Inkbit has been working on a workaround to this problem for a number of years. The company has built a printer featuring a platform that moves up and down beneath multiple inkjet units, a UV-curing unit, and a scanning unit. After a layer has been deposited and cured, the scanner creates a depth map of the print surface, which is then compared against the 3D model to work out how to adjust the rate of deposition from the inkjet units to even out any irregularities. Areas that received too much resin on the previous layer receive less on the next, and vice versa.

This means the printer doesn’t require any contact with the materials once they’ve been deposited, says Robert Katzschmann, a robotics professor at ETH Zurich who led the research. “That leads to all kinds of benefits, because now you can use chemistries that take longer to polymerize, that take longer to harden out, and that opens up a whole new space of much more useful materials.”

“We can actually now create a structure or a robot in one shot. It might require maybe adding a motor here or there, but the actual complexity of the structure is all there.”

—Robert Katzschmann, ETH Zurich

Previously, Inkbit had been using a scanning approach that could capture images of areas only 2 centimeters across at a time. This process had to be repeated multiple times before all the images were stitched together and analyzed, which significantly slowed down fabrication times. The new technique uses a much faster laser scanning system—the device can now print 660 times as fast as before. In addition, the team has now demonstrated that they can print with elastic polymers called thiol-enes. These materials cure slowly, but they’re much springier and more durable than acrylates, the rubberlike materials that are normally used in commercial 3D inkjet printers.

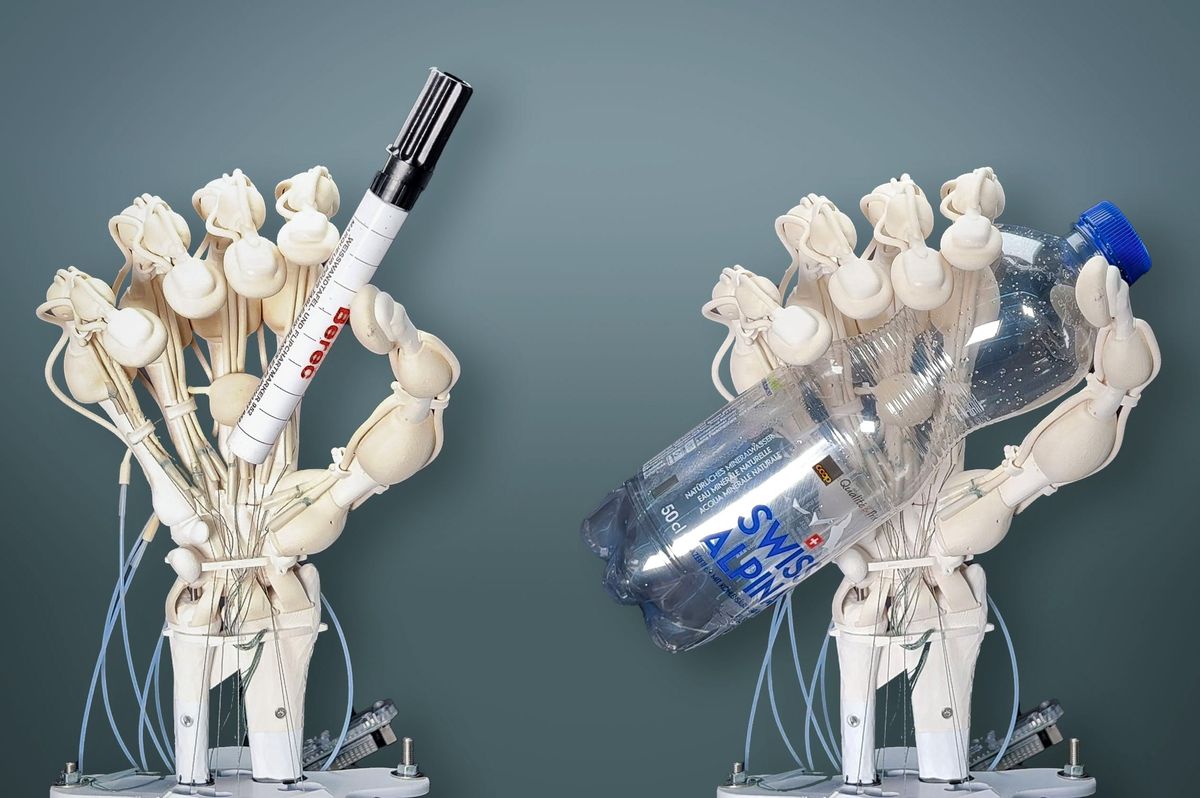

To demonstrate the potential of the new 3D printing process, the researchers printed a robotic hand. The device features rigid bones modeled on MRI scans of human hands and elastic tendons that can be connected to servos to curl the fingers in toward the palm. Each fingertip also features a thin membrane with a small cavity behind, which is connected to a long tube printed into the structure of the finger. When the finger touches something, the cavity is compressed, causing the pressure inside the tube to rise. This is picked up by a pressure sensor at the end of the tube, and this signal is used to tell the fingers to stop curling once a certain pressure has been reached.

The researchers used the hand to grip a variety of objects, including a pen and a water bottle and to touch its thumb to each of its fingertips. Critically, all of the functional parts of the robotic hand, apart from the servos and the pressure sensors, were produced in a single printing job. “What we see as novel about our work is that we can actually now create a structure or a robot in one shot,” says Katzschmann. “It might require maybe adding a motor here or there, but the actual complexity of the structure is all there.”

The researchers also created a pneumatically powered six-legged robot with a gripper that was able to walk back and forth and pick up a box of Tic-Tacs, and a pump modeled on the human heart, featuring one-way valves and internal pressure sensors, that was capable of pumping 2.3 liters of fluid a minute.

Future work will look to further expand the number of materials that the printer can use, says Katzschmann. They are restricted to materials that can be cured using UV light and that aren’t too viscous to work in an inkjet printer. But these could include things like hard epoxies, hydrogels suitable for tissue engineering, or even conductive polymers that could make it possible to print electronic circuits into devices.

Edd Gent is a freelance science and technology writer based in Bengaluru, India. His writing focuses on emerging technologies across computing, engineering, energy and bioscience. He's on Twitter at @EddytheGent and email at edd dot gent at outlook dot com. His PGP fingerprint is ABB8 6BB3 3E69 C4A7 EC91 611B 5C12 193D 5DFC C01B. His public key is here. DM for Signal info.