An absolutely enormous amount of effort is being devoted to teaching mobile manipulator robots how to get things done in environments that are designed for humans. The problem is that unstructured human-friendly environments are not, in general, robot friendly: a daily task that we perform without even thinking about it can be, from the perspective of a robot, somewhere between very difficult and impossible.

A great deal of this aforementioned enormous amount of effort has been focused on making robots as human-like as possible, based on the idea that the more human-like a robot is, the better it'll be able to deal with human environments. So, we're trying to make robots with legs, trying to implement vision systems and databases that let robots look at something and identify what it is, and trying to design anthropomorphic hands that give robots the ability to grasp anything that a human can.

But robots are not really ever going to be like humans (not anytime soon, at least), and it's way easier to just give up on that stuff and instead make some relatively inexpensive and minor modifications to the human environment to make it vastly more friendly to robots. We posted about one example of this last week: using RFID tags to help robots find and identify objects. Here's another one, involving a very simple, very cheap 3D printed adapter that makes it easy for a robot with a simple gripper to pick up and use household tools designed for human hands.

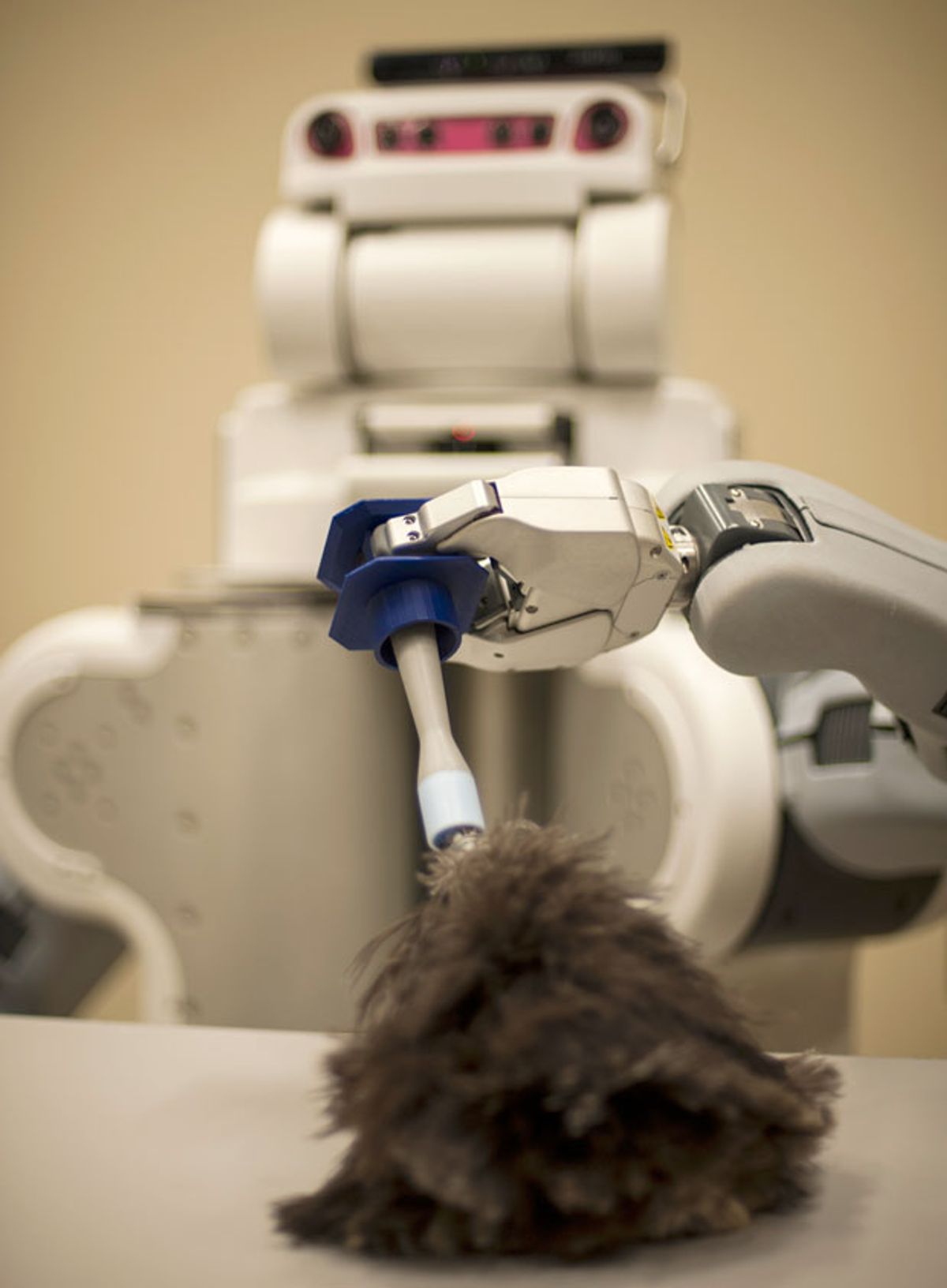

Griple, developed by Zhe Xu and Maya Cakmak at the Human Centered Robotics Lab at the University of Washington, in Seattle, is a US $10 3D printed adapter that slides onto a wide variety of household cleaning tools designed for humans to use with one hand. All you have to do is put Griple on the handle of one of these tools, add some Sugru self-curing silicone to lock it in place, and that's it. Griple makes it easy for a robot with a relatively simple gripper (like a Baxter or a PR2) to then pick up and use these tools, without having to deal with any kind of grasping issues.

Griple neatly solves many common issues with all three stages of tool use: grasping, applying, and placing. The researchers ran a series of experiments where their PR2 ("Rosie2") used household tools including sponges, dusters, sweepers, and scrubbers to do things like wiping off a whiteboard, sweeping dust off of a table, and removing lint from fabric. Without Griple, Rosie's average cleaning success rate was 86 percent. With Griple, it was 99 percent. Not bad for a $10 investment, right?

The other advantage of Griple is that it provides a very easy way for a robot to identify, and even localize, the tools that it needs. If you're making a Griple for a tool, it would be simple to attach a big fat QR code to it at the same time, which the robot can use vision to identify. Or to get slightly more complicated (but only slightly), you could embed an RFID tag into Griple to do away with vision entirely.

At the moment, attaching a Griple to a tool is a more or less a permanent modification, which the researchers acknowledge might render those tools unusable (or at least, very uncomfortable) for humans. Most of these tools are so cheap as to be nearly disposable, but the researchers are already thinking about ways in which a Griple might be able to be easily detachable. Or best case scenario, your robot might be able to attach a Griple to a tool all by itself, whenever it needs to.

While we're certainly in favor of designing robots with awesome vision systems, adaptable programming, and versatile anthropomorphic hands, all that stuff is very difficult and expensive. We want robots in our homes now, or at least soon, and to do that, it's going to require some clever compromises like Griple.

"Enhanced Robotic Cleaning With a Low-Cost Tool Attachment," by Zhe Xu and Maya Cakmak from the University of Washington, was presented last month at the 2014 IEEE International Conference on Intelligent Robots and Systems (IROS) in Chicago.

[ UW Human Centered Robotics Lab ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.