Millions of athletes and arthritis patients turn to disposable pain relief patches designed to soothe aching joints and muscles. The new development of a flexible smart patch could eventually enable users to wirelessly control the exact temperature of their heat therapy with their smartphones.

The smart patch relies upon the design of stretchable, flexible copper springs to conduct power to a series of tiny, interconnected heating pads. Engineers at King Abdullah University of Science and Technology in Saudi Arabia hope their smart patch could eventually begin to replace the 4.2 billion chemical-based patches sold for pain relief every year. But first, they want to introduce more flexible electronic components to replace the electronics hardware and battery in their current prototype.

“We can make anything from silicon or other inorganic thin films with pre-fabricated devices stretchable and flexible,” says Muhammad Mustafa Hussain, an associate professor of electrical engineering at King Abdullah University of Science and Technology in Saudi Arabia. “That’s kind of our forte.”

Most flexible electronics have yet to become ordinary products sitting on store shelves. But Hussain has always wanted to apply the promise of flexible electronics to simple, inexpensive products that anyone could buy. His team is talking with a company that represents a major brand in thermal patches about the possibility of developing the lab prototype into a commercial product.

The idea began in Hussain’s personal life. In October 2012, he noticed the patches that his mother used to ease arthritis pain in her finger and knee joints. Such patches are chemical based, made in many sizes and shapes for different parts of the body, and can become expensive over time because they are single-use products. Something clicked in Hussain’s mind; why not make a flexible and stretchable heating patch that was reusable and cost less than the chemical-based patches?

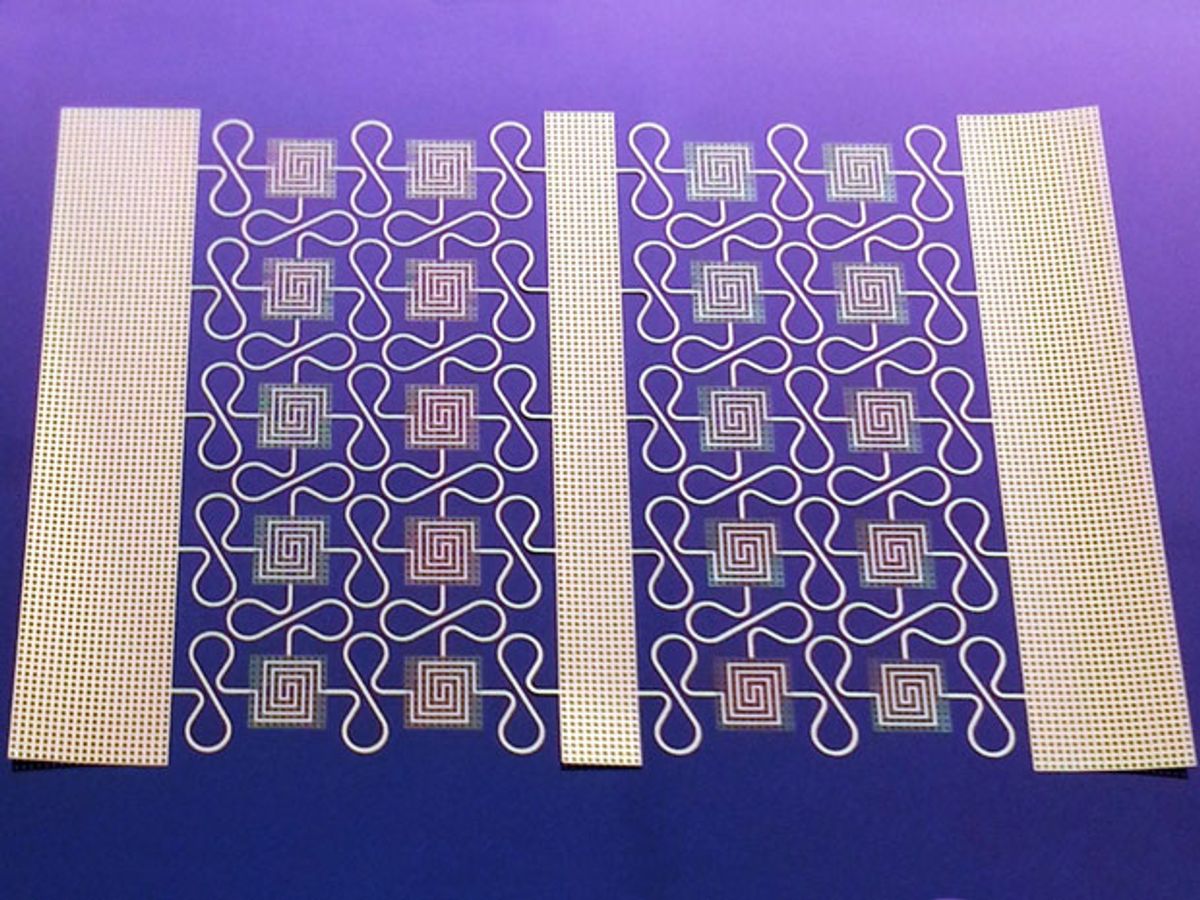

To create the flexible patch, Hussain’s group turned to copper, because it’s common in electronics and inexpensive. But the researchers faced the challenge of making copper interconnects that could survive stretching and flexing beyond the metal’s normal yield strain of just 20 to 25 percent.

They eventually settled upon a known fractal pattern of repeating shapes—each shape resembling a figure eight drawn in a single, unbroken line that never intersects itself. That pattern enabled the copper interconnects to survive stretching up to 800 percent beyond their starting size.

“The design we used… is not new,” Hussain explains. “But we did meticulous simulation and modeling to see if we could identify a design rule that uses copper in a way that allows the design to stretch to the maximum, while absorbing the deformation strain.”

The prototype is detailed in an online paper published on 3 Dec 2014 in the journal Advanced Healthcare Materials. Aftab Hussain, a Ph.D. candidate at King Abdullah University of Science and Technology and first author on the paper, also became a finalist at the Falling Walls conference in Berlin after presenting the group’s work in Berlin, Germany this past November.

Beyond the simulations, the researchers built 40 prototypes of the smart patch and put them through continuous flexing and stretching tests lasting up to half a year in Saudi Arabia, which is typically very humid. They wanted to be sure the patches could survive as reusable devices that would last far longer than the disposable chemical-based patches.

Each patch act as its own temperature sensor to ensure—detecting the increase in the electrical resistance of copper that accompanies any increase in temperature.

The prototype patch uses off-the-shelf control electronics such as an Arduino Uno microcontroller board and a Seeed Studio Bluetooth Shield to provide wireless communication with an Android smartphone. Researchers tested the patch on themselves while using a smartphone to adjust the patch’s heating temperature.

The whole system is powered by standard coin batteries. The prototype system draws about 1.5 watts of power at its maximum operating temperature, which would drain an ordinary coin battery in about two hours. But Hussain envisions a much longer time between battery charges for more typical user scenarios.

“If we assume that a patient is going to use a heating patch on his or her finger at a temperature which is comfortable for the body but effective for pain for one hour every day for 14 days, they can use just one coin battery before needing to recharge,” Hussain says.

The ultimate goal for Hussain’s team is to make “everything flexible and stretchable” in any final commercial product. They have already published papers about their experiments with stretchable arrangements of silicon fabric that could pave the way for a fully flexible smart patch. Hussain estimates that a final commercial version could eventually begin selling at less than US $4 each at scale of half a billion being produced each year.

“Product engineers will have cool ideas to make it really robust and much more effective in that sense,” Hussain says. “But I think we have taken the first step.”

Jeremy Hsu has been working as a science and technology journalist in New York City since 2008. He has written on subjects as diverse as supercomputing and wearable electronics for IEEE Spectrum. When he’s not trying to wrap his head around the latest quantum computing news for Spectrum, he also contributes to a variety of publications such as Scientific American, Discover, Popular Science, and others. He is a graduate of New York University’s Science, Health & Environmental Reporting Program.