Researchers at Purdue University have developed a new design employing carbon nanotubes and small copper spheres that wicks water passively towards hot electronics that could meet the challenges brought on by increasing frequency speeds in chips.

The problem of overheating electronics is well-documented and in the past the issue has been addressed with bigger and bigger fans. But with chip features shrinking below 50 nanometers the fan solution is just not cutting it.

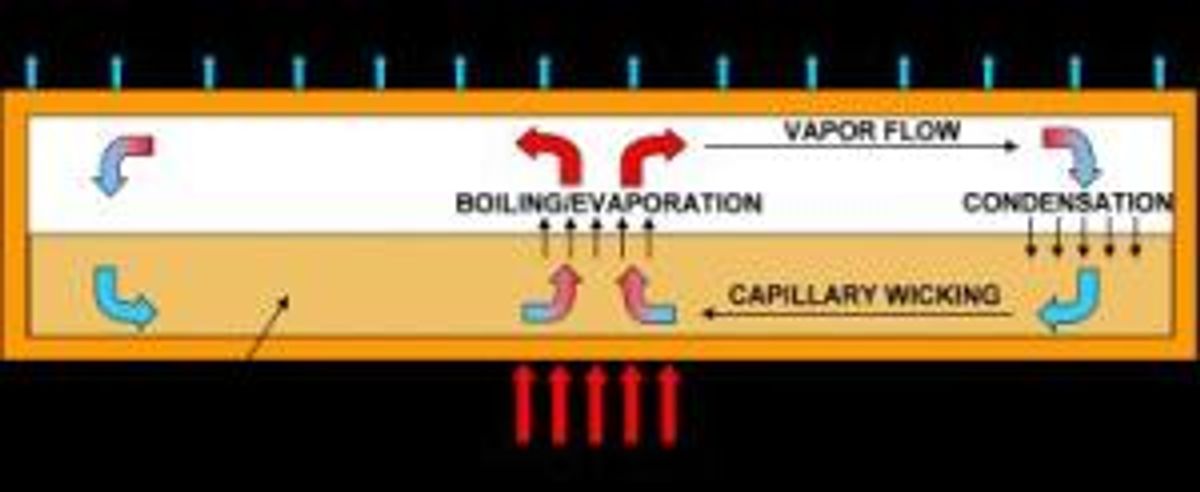

The Purdue researchers, led by Suresh V. Garimella, came up with a design that uses water as the coolant liquid and transfers the water to an ultrathin thermal ground plane. The design naturally pushes the water through obviating the need for a pump and through the use of microfluidic design is able to boil the water fully, which allows the wicking away of more heat.

One of the keys to the design was creating pore sizes that were smaller than previous sintered designs. While achieving the smaller pore size the researchers had to overcome the problem of frictional resistance on the liquid that would come with more pores (the smaller they are the more of them there are). It’s here that the carbon nanotubes came into play as the researchers used 50-nm copper coated carbon nanotubes to make the small pores.

This is not the first time that Purdue researchers have worked with carbon nanotubes to dissipate heat in chips. A few years back they were looking at growing millions of carbon nanotubes on a chip like grass to dissipate the heat generated from chips, and showed promise in better conducting heat in passively cooled systems such as cellphones than thermal greases now commonly used.

A Defense Advanced Research Projects Agency (DARPA) grant is funding this mos recent research and the Purdue researchers are collaborating with Raytheon, Thermacore Inc. and Georgia Tech on the project.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.