A staggering fact is that motors and motor driven systems account for between 43 percent and 46 percent of all global electricity consumption. Needless to say, if electric motors could be made to run more efficiently, energy consumption would fall. With research out of Rice University back in 2011 demonstrating that carbon nanotubes braided into wires could outperform copper in conducting electricity, it looked like there would soon be a new way to create those improved efficiencies.

Building on that research, a team at the Lappeenranta University of Technology (LUT) in Finland hasreplaced the copper windings used to conduct electricity in electric motors with a woven material made from threads of carbon nanotubes and achieved remarkable new efficiencies in the motors.

"If we keep the electrical machine design parameters unchanged and only replace copper with future carbon nanotube wires, it is possible to reduce the Joule losses in the windings to half of the present-day machine losses,” said Professor Juha Pyrhönen, who has led the design of the prototype at LUT, in a press release.

Copper windings have traditionally been used because they are the second best metal at conducting electricity at room temperature, and they come relatively cheap. However, despite their high conductivity, they do offer some resistance—to the point where Joule losses are often referred to as “copper losses.”

Meanwhile carbon nanotubes have conductivity far beyond the best metals and their limits of conductivity have not been found: some have been measured at 100 megasiemens/meter, compared to ultra-pure copper at 58.65 MS/m. With this kind of conductivity, carbon nanotube-based windings could result in double the conductivity of today’s copper windings, according to the Finnish researchers. And as Pyrhönen claimed, Joule losses could be cut in half with the carbon nanotube yarn.

In the prototype motor made by the Finnish team, the carbon nanotube yarns are spun and converted into an isolated tape by a Japanese-Dutch company Teijin Aramid. (The actual spinning technology was developed in collaboration with Rice University.) Since this industrial use of the carbon nanotube yarn is still at its early stages, the production capacity has not been ramped up. This will have to be addressed if the new wire is to replace the ubiquitous copper windings.

However, the performance improvements are significant enough to warrant at least an investigation into whether it can become a realistic replacement for copper wiring.

"There is a significant improvement potential in the electrical machines, but we are now facing the limits of material physics set by traditional winding materials,” said Dr. Marcin Otto, business development manager of Teijin Aramid, in the press release. “We expect that in the future, the conductivity of carbon nanotube yarns could be even three times the practical conductivity of copper in electrical machines. In addition, carbon is abundant while copper needs to be mined or recycled by heavy industrial processes."

Sounds as though there’s a company that has a firm belief in the potential of their product in this application. And with the potential to put a big dent in the 45 percent of global electricity consumption that comes from the use of electrical motors, why not be confident?

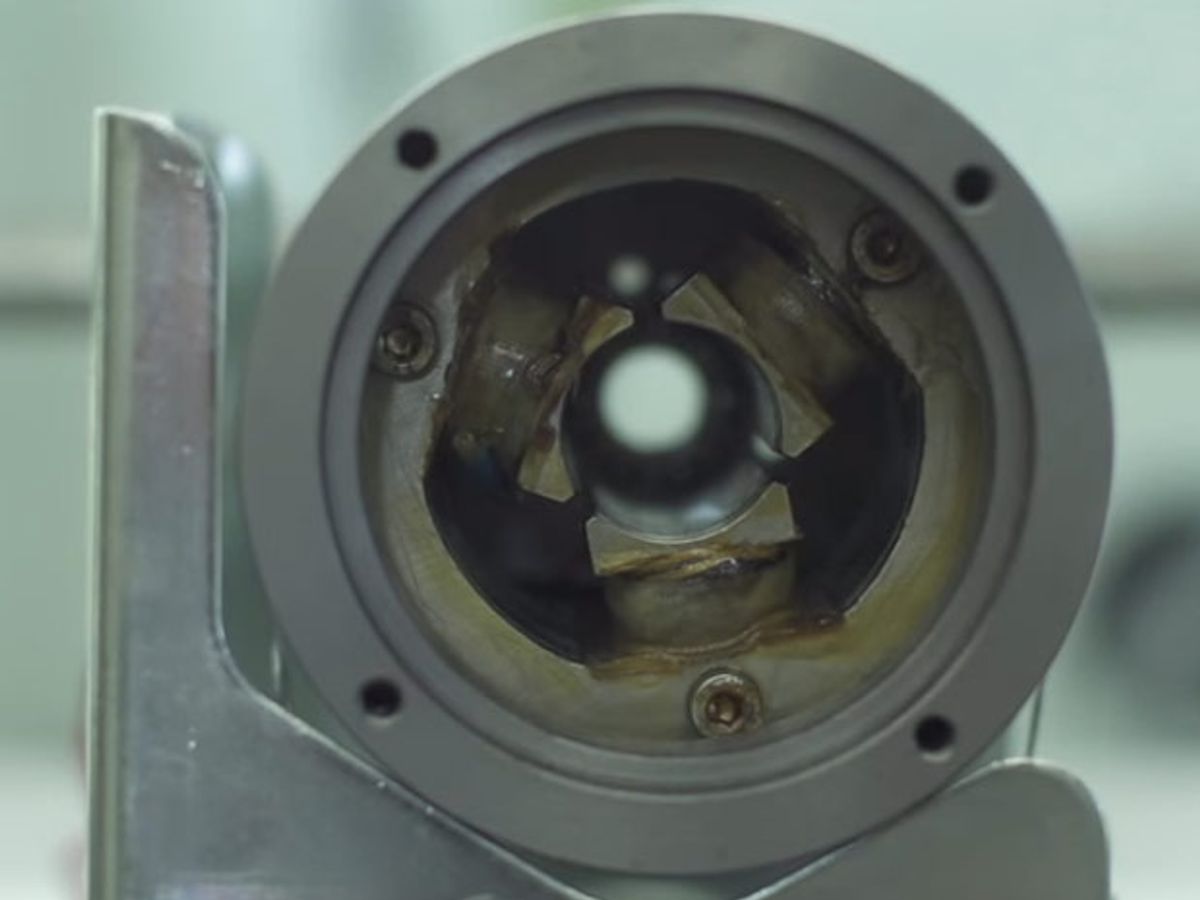

A video of the motor equipped with the carbon nanotube windings is below.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.