Electrochromic polymers that change color when a voltage is applied already have a pretty impressive wow factor, turning windows from clear to tinted with a flip of a switch.

Now researchers at Sandia National Laboratories have put this impressive feat to shame. They have devised a way to make the usually slow responding electrochromic polymers change colors fast enough so that they could be used as a material for flat-panel TVs.

The problem that has handicapped electrochromic polymers up to now has been that in order for them to achieve a good contrast between bright and dark pixels it has been necessary for them to be relatively thick. While this is good for creating contrast, it slows down the diffusion times for ions and electrons to change the polymer’s charge state. This has limited their use to static displays or darkening windows.

The Sandia researchers overcome this limitation by making the electrochromic polymer only nanometers thick and relying on plasmonics, which exploits the waves of electrons (plasmons) that are created on the surface of a metal when it is struck by photons.

In research published in the journal Nature Communications, the Sandia scientists leveraged these two key design elements by cutting nanoscale slits into an aluminum sheet that are oriented vertically to the incoming light. This thin sheet of aluminum is coated on the opposite side of the incoming light with the electrochromic polymer. When the light hits the aluminum slits, the photons trigger the electrons to act as surface plasmon polaritons.

The distance between the slits in each array (or pitch) correspond to different wavelengths of light, so each pitch results in different colors. This means there are different arrays of slits: one each for red, green, and blue. The wavelengths of light corresponding to red, green, and blue are transmitted through the array of slits and travel along the interface of the polymer and the aluminum substrate.

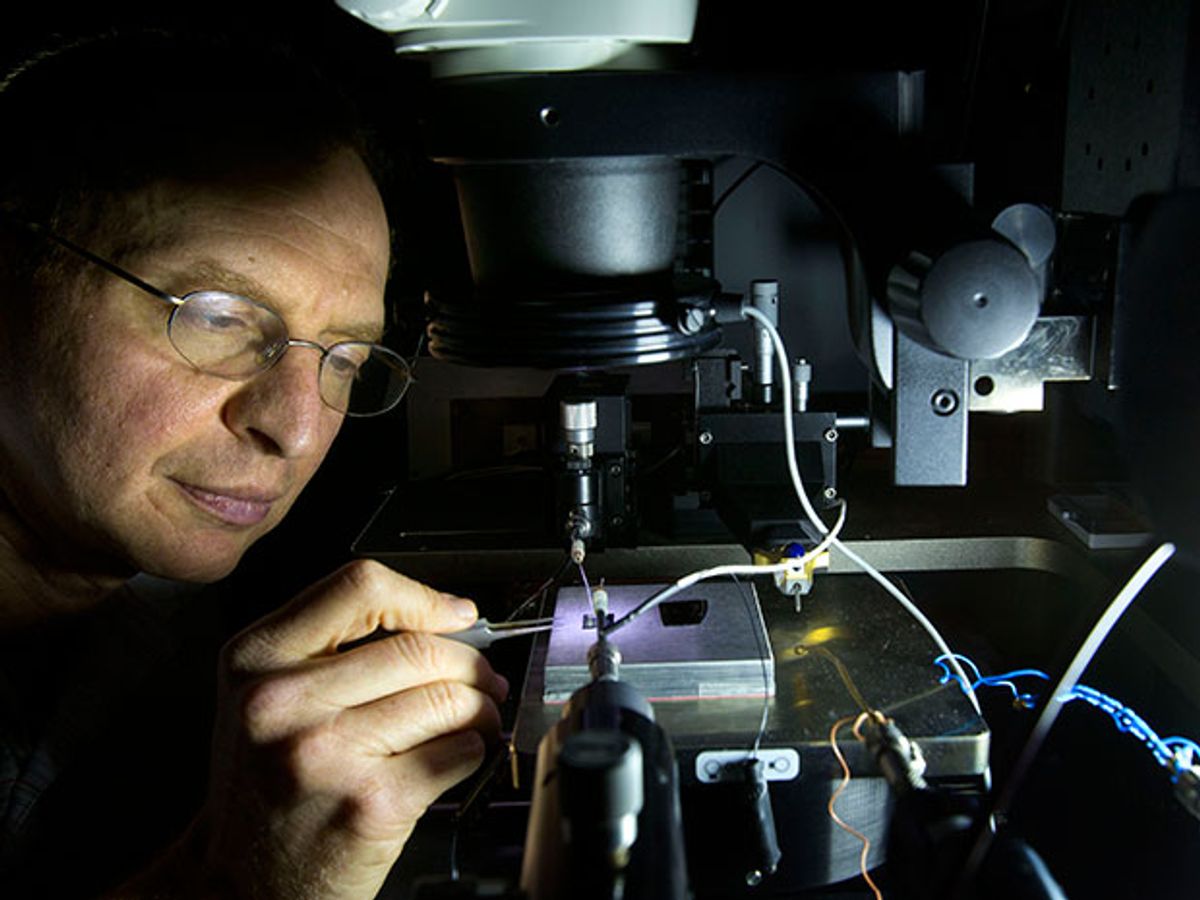

“Most of our pixels consisted of 10x10 micrometers slit arrays cut into an aluminum film deposited onto glass substrates with a silicon nitride layer,” explained Alec Talin of Sandia Labs, who led the research, in an e-mail interview with IEEE Spectrum. “Each pixel area is 10^-6 cm2, meaning that we could pack over 6 million pixels in a square inch. We also demonstrated larger pixels that were 100x100 um.”

Talin added: “Our pixels were not individually addressable on a single substrate, as one would have in a commercial display, but the technology for this is the same as would be used for LCD displays.”

Since the electrochromic polymer is very thin it takes comparatively little time to change its charge state so that it can absorb the colored light. Meanwhile the light has traveled a relatively long distance along the surface of the aluminum slits. This is because the depth of the slits themselves is wider than the thickness of the polymer. The result is that a good contrast is made between the light and the dark pixels while still managing to speed up the changing of the charge state of the polymer.

“As a surface plasmon polariton, light is confined to the aluminum/polymer interface, traveling along the depth of the slit, which can be 0.5 micrometers or more,” said Talin. “The actual thickness of the electrochromic layer is only ~15 nanometers, and that is the thickness ‘seen’ by the ions and electrons, which generally move slowly and limit the speed of electrochromic displays.”

There are some important engineering issues to address before flat-panel TVs start using electrochromic polymers.

First, Talin notes that a substitute a polymer electrolyte would need to be developed for the liquid electrolyte that was used in the research. “This could be similar to the polymers used in Li-polymer batteries, for example,” he said.

The second task, according to Talin, would be to demonstrate a display that could be used in transmission mode with a backlight for indoor use, as well as in reflection mode for outdoors use. “I think this would be very competitive with existing technologies,” he added.

Finally, a key engineering hurdle would be to integrate an array of individually addressable pixels to show actual video.

In their continuing research, Talin and his colleagues are currently considering solid-state organic and inorganic electrochromic materials and electrolytes, both from the standpoint of performance and manufacturability, to improve on their results.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.