As the world continues to try and move away from fossil fuels, researchers are looking for new ways to store energy produced from greener sources like solar panels. As part of that effort, a team of researchers from Harvard’s Wyss Institute for Biologically Inspired Engineering and MIT have developed a supercapacitor using only cement, water, and a form of carbon called carbon black.

Energy produced from renewable sources often needs to be stored for a rainy day. But batteries are not always the best option. They take time to charge, and building them requires difficult-to-source materials like lithium which can be costly and harmful to the environment.

Franz-Josef Ulm, a professor of civil and environmental engineering at MIT, and his colleagues were interested in developing supercapacitors with readily available materials, like cement, to not only fill a gap left by battery technology but to also address another environmental issue: concrete’s carbon footprint. Their work was published 31 July in the journal PNAS.

“One [motivating issue] is the enormous environmental footprint of the worldwide cement and concrete production which amounts to roughly 8 percent of the worldwide CO2 emissions,” says Ulm, who is senior author on the new paper. “We can use this energy-storage solution to support the urgently needed transition from fossil fuels to renewable energy—brick by brick, wall by wall, road by road.”

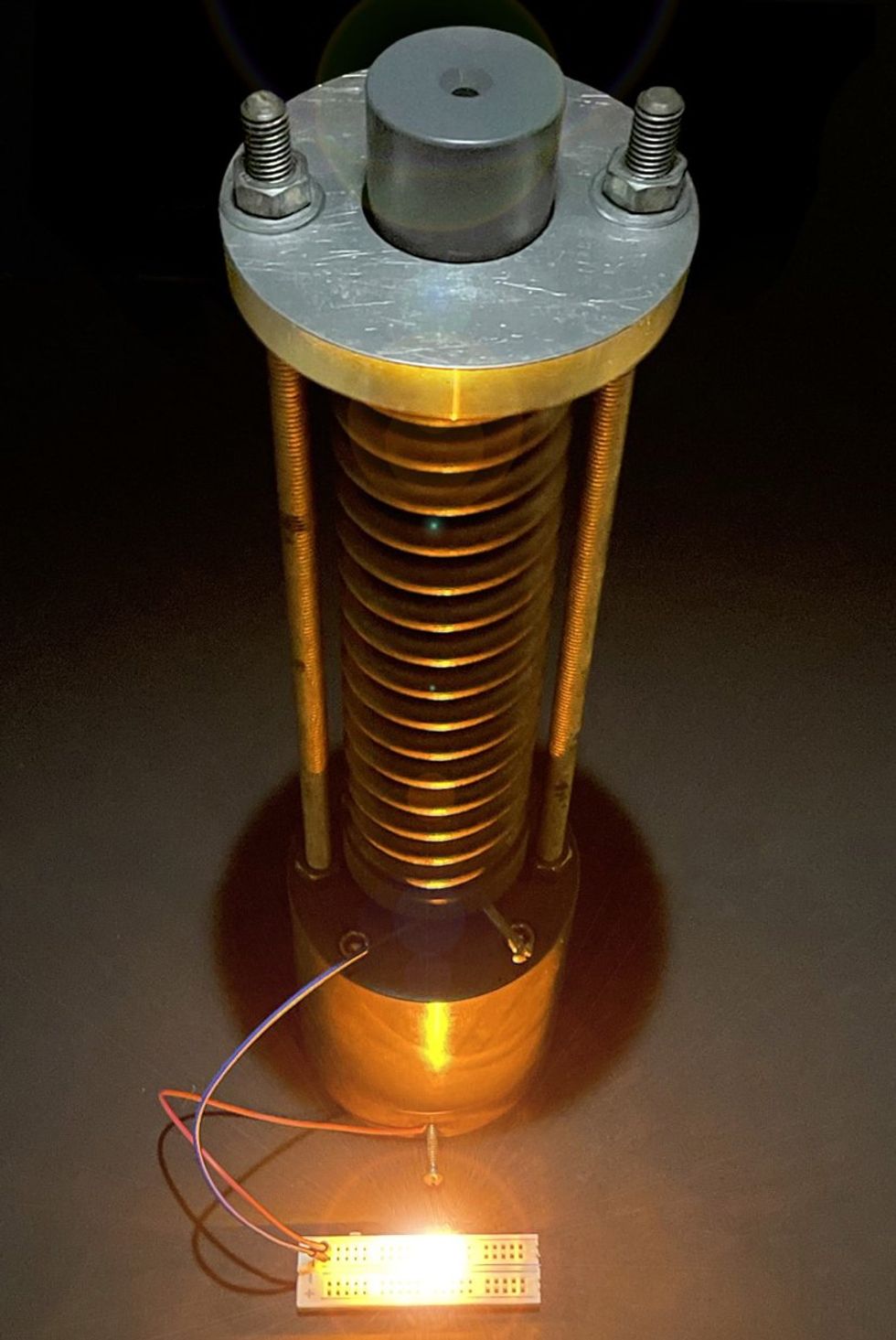

The team sought to redeem cement’s image by using it as the base for their supercapacitor’s electrodes. Unlike batteries, which use chemical reactions to hold and discharge electricity, supercapacitors work by creating a charge difference between two conductive plates. This charge can be maintained for a long time and discharged quickly when needed.

To build their supercapacitor, the team mixed together a paste made of cement and water, and then introduced a small amount of carbon black—a fine, charcoal-like form of carbon that has been used as a pigment and writing material for thousands of years. For instance, carbon black was used to pen the Dead Sea Scrolls in the 3rd century BCE. History aside, carbon black is also a highly conductive material.

As the cement mixture cured, the water was absorbed and left behind a branching network of tunnels that the carbon black filled. The end result is that the cement paste is filled with a large surface area of conductive, wirelike tunnels, without expanding the overall volume of the electrode.

Ulm says that the reaction of carbon black in the electrode is a crucial discovery because it could make scaling this supercapacitor much simpler.

“What we found is that the maximum energy storage capacity only depends on the specific surface of the carbon black,” Ulm says. “Since this carbon black is space-filling—thanks to the magic of chemistry!—we can simply increase the volume to create large-scale bulk energy solutions.”

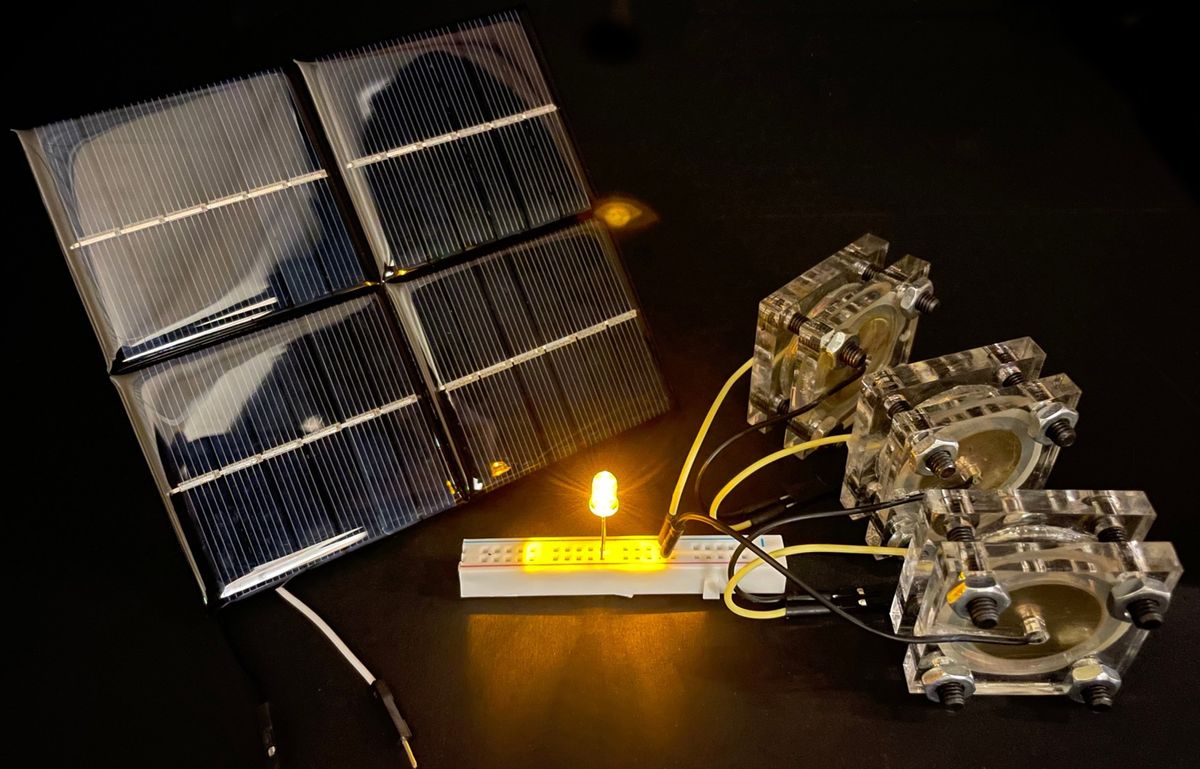

The team completed the supercapacitor by soaking two electrodes in an electrolyte solution to provide charged particles to the system. In their trials, they fabricated button-size capacitors capable of holding 1 volt of charge and determined that the capacitor was able to maintain its storage capacity with minimal loss over 10,000 charge-discharge cycles. Three of the 1-V supercapacitors were also able to charge a 3-V LED.

The team also developed button-size capacitors with different ratios of cement to carbon black but found that while adding more carbon black (above 10 percent by volume) to the mixture increased its storage capacity, this came at the cost of the cement’s structural integrity. And for the use cases that Ulm and colleagues have in mind, the structural strength of the cement is essential.

Concrete is already used to construct roads, and so the team sees an opportunity for concrete roads that could also wirelessly charge cars as they’re driving, similar to wireless charging pads for smartphones. “Such self-charging roads already exist, but use coils embedded in the road system and connected (mostly) to a grid energy source. The energy in our system would be harvested from clean energy sources and stored into the pavement structure.”

The team also has plans to integrate these supercapacitors into the foundations of residential homes. They estimate that a 45 cubic meter sample of their supercapacitor could hold 10 kilowatt-hours of energy—equivalent to about one-third of an average U.S. household’s daily electricity usage.

As the next step, Ulm says the team is now focused on developing a 12-V supercapacitor using these materials. “[We’ll] continue to have fun…pushing this technology to its limit,” he says.

This story was updated on 4 August 2023 to correct and clarify several distinctions between concrete and cement.

- Graphene-based Supercapacitors Take Another Crack at All-electric ... ›

- Supercapacitors Get Smaller Than Ever - IEEE Spectrum ›

- Supercapacitors: Solving AI's Energy Spikes - IEEE Spectrum ›

Sarah Wells is a science and technology journalist interested in how innovation and research intersect with our daily lives. She has written for a number of national publications, including Popular Mechanics, Popular Science, and Motherboard.