When NASA first sent humans to the moon, astronauts often made risky blind landings on the lunar surface because of billowing dust clouds churned up during their descent. Astronauts could avoid repeating those harrowing experiences during future missions to the moon with the help of a 3D-printed lunar landing pad designed by a NASA-backed student team.

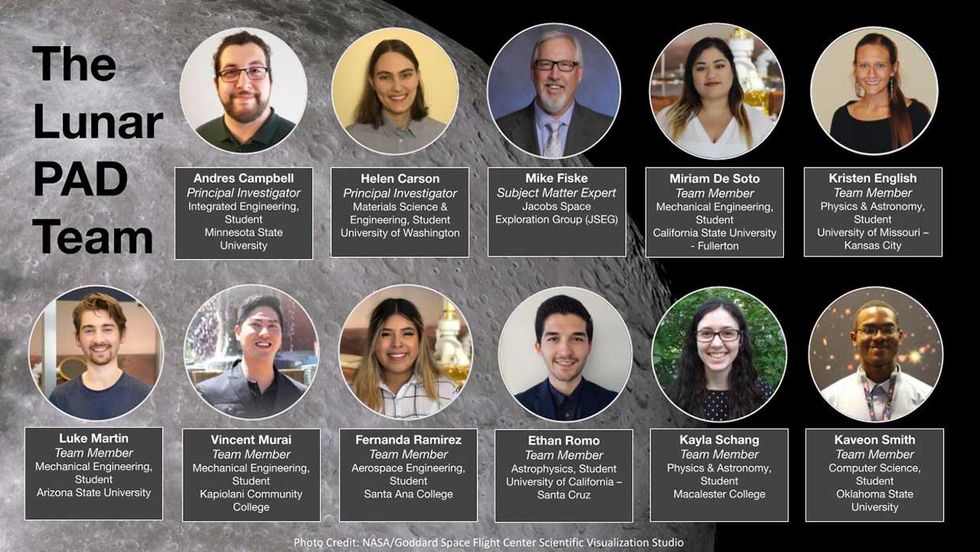

The landing pad developed by students from 10 U.S. universities and colleges is shaped to minimize the lunar dust clouds stirred up by rocket landing burns and could eventually be made from lunar regolith material found on the moon. A prototype of the pad is scheduled to undergo a rocket hot fire test under the watchful eye of both students and NASA engineers at Camp Swift, Texas in early March.

“We showed that you can 3D print the structure with our existing prototype,” says Helen Carson, a material science and engineering student at the University of Washington in Seattle and a principal investigator for the Lunar PAD team. “For now, we have a lot of flexibility with different directions we can take depending on how the materials develop.”

Such a Lunar PAD concept could prove especially helpful with NASA’s current roadmap aimed at returning humans to the moon through the Artemis Program; the U.S. space agency has already issued contracts to companies such as SpaceX, Blue Origin, and Dynetics to start developing ideas for a human lunar lander. Any future moon landings could benefit from reducing the risk of possible catastrophe that comes from flying blind in a dust cloud. Furthermore, dust and rocks accelerated to high speeds by engine exhaust could pose a serious danger to astronauts, robots, or other equipment already on the surface of the moon.

The Lunar PAD team first came together during NASA’s L’SPACE (Lucy Student Pipeline Accelerator and Competency Enabler) Virtual Academy held in the summer of 2019. Carson and her colleagues won funding from the NASA Proposal Writing and Evaluation process to move forward on the project and to make a presentation at NASA Marshall Space Flight Center in June 2020. At that event, additional funding was awarded so that the team could print and test their pad prototype. The students also presented a paper on Lunar PAD at the AIAA SciTech Forum and Exposition that was held 19-21 January 2021.

The team’s early idea included creating an inflatable deflector that would be inflated by the rocket engine exhaust and block any debris blasted outward from the landing (or launch) zone of the pad. But that would have required transporting flexible yet durable materials manufactured on Earth to the moon.

“That got pretty complicated with material choice and design, and the actual transportation of it,” says Luke Martin, a mechanical engineering student at Arizona State University. “So we tried coming up with other more in-situ resource ideas.”

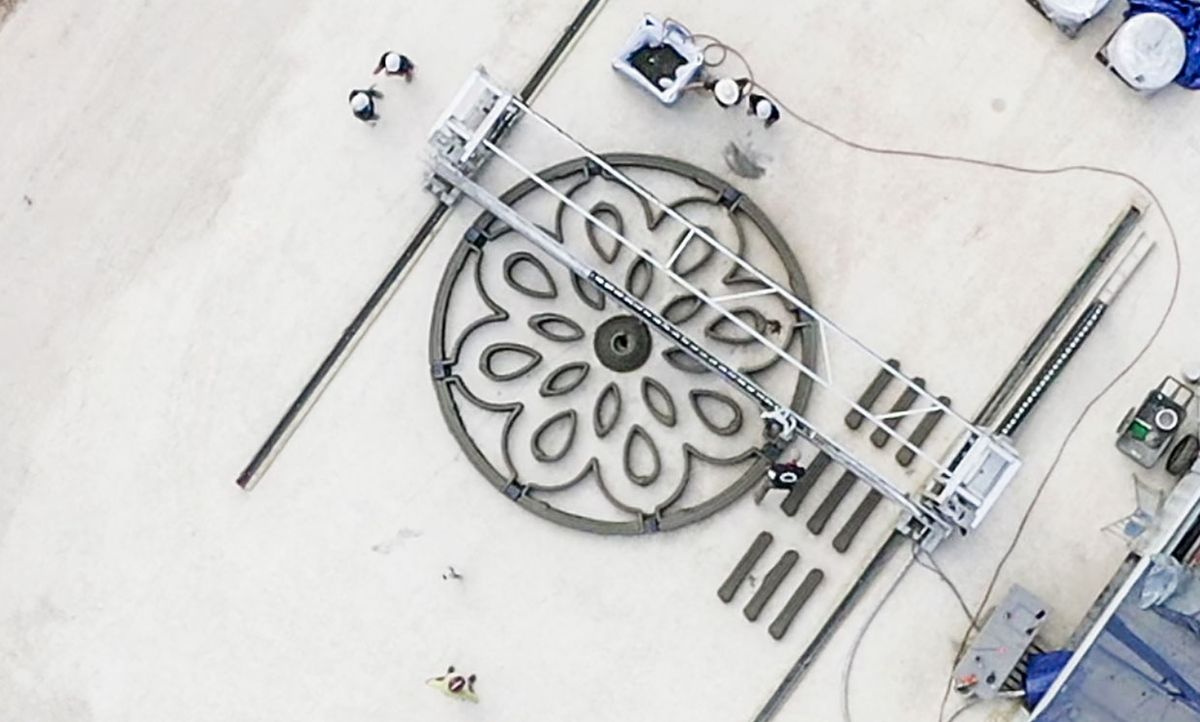

Lunar PAD currently has a top surface layer where rockets and lunar landers could both land and launch. But the key to mitigating the worst of any dust clouds or small particles accelerated to high velocities is the open interior space of the pad that sits below the top layer. Slanted grates in the top layer would channel the rocket exhaust into the interior space.

The pad’s interior includes vent dividers—some shaped like teardrops or leaflets—that help channel the rocket exhaust and any accompanying dust or rock particles outward from the center of the pad. The cosmetically appealing layout of the vent dividers—which some liken to flower petals—proved to be the most efficient pattern that came out of numerous iterations tested through flow simulations.

“It's very practical, very efficient, and just so happens to also be very beautiful,” says Vincent Murai, a mechanical engineering student at Kapiolani Community College in Honolulu.

The exhaust and any accompanying particles leave the pad’s interior space through specific exits, called Kinetic Energy Diffusers, embedded in the outside walls of the circular pad. Such diffusers consist of hollow rectangular blocks that could also include fans to convert some of the rocket exhaust’s excess energy into the circular fan motion and block some particles with the turning fan blades.

Any high-velocity particles that get through the fans would also encounter deflectors placed right outside the exits in the full-scale version of the pad. And an “apron” surrounding the landing pad would also include a perimeter deflector wall to direct any remaining exhaust-propelled particles up and away from any nearby spacecraft, people, or structures.

The subscale prototype of the pad was manufactured by a gantry-style 3D printer developed by the Austin-based company ICON. The company is already working with NASA to adapt its 3D printing technology for space-based construction on the moon and Mars.

3D printing the main layers of the subscale pad prototype took up just one day. The team also spent three additional days on tasks such as using the printer to fill various components with concrete and patching or smoothing certain parts of the pad. People also had to manually install fiber optic sensors to detect changes in strain and temperature.

But the most labor-intensive and hands-on part of the construction involved trimming and placing pre-cut blocks of water-soluble foam to provide temporary structural support for overhanging areas of the pad. Full-scale construction of such a pad on the moon or Mars would require a different and ideally more efficient solution for providing such removable supports.

“It became especially apparent after a few days of of cutting and wrapping and inserting foam that it's probably not the best use of an astronaut’s time,” says Andres Campbell, an integrated engineering student with an emphasis on aerospace engineering at Minnesota State University in Mankato and a principal investigator for the team. “This would also be something that would be robotically complex to do.”

In any case, a full-scale and operational Lunar PAD would not have to handle the dust mitigation work on its own. For example, Carson originally proposed an electrodynamic dust shielding technology that would passively push dust off the landing pad by taking advantage of the charged nature of lunar dust. Automated cleaning tools such what Campbell described as a “space Roomba” robot could also help keep the launch and landing zone dust free.

“The idea that you can combine the pad with not just electrodynamic dust shielding but any sort of passive dust mitigation system is still worth consideration,” Carson says. “Because in addition to that pad, you would still have dust that could be kicked up from other activities on the surface.”

The 3D-printed pad concept could eventually prove useful for future missions to Mars and other destinations. Such pad designs would have to account for some differences in atmosphere and gravity on rocket plumes and dust clouds, not to mention factors such as the moon’s electrostatically charged dust particles and Martian dust storms. Still, the team designed the pad to potentially work beyond lunar landing scenarios.

“Our goal was to build a reusable pad for all extraterrestrial environments,” Murai says.

Jeremy Hsu has been working as a science and technology journalist in New York City since 2008. He has written on subjects as diverse as supercomputing and wearable electronics for IEEE Spectrum. When he’s not trying to wrap his head around the latest quantum computing news for Spectrum, he also contributes to a variety of publications such as Scientific American, Discover, Popular Science, and others. He is a graduate of New York University’s Science, Health & Environmental Reporting Program.