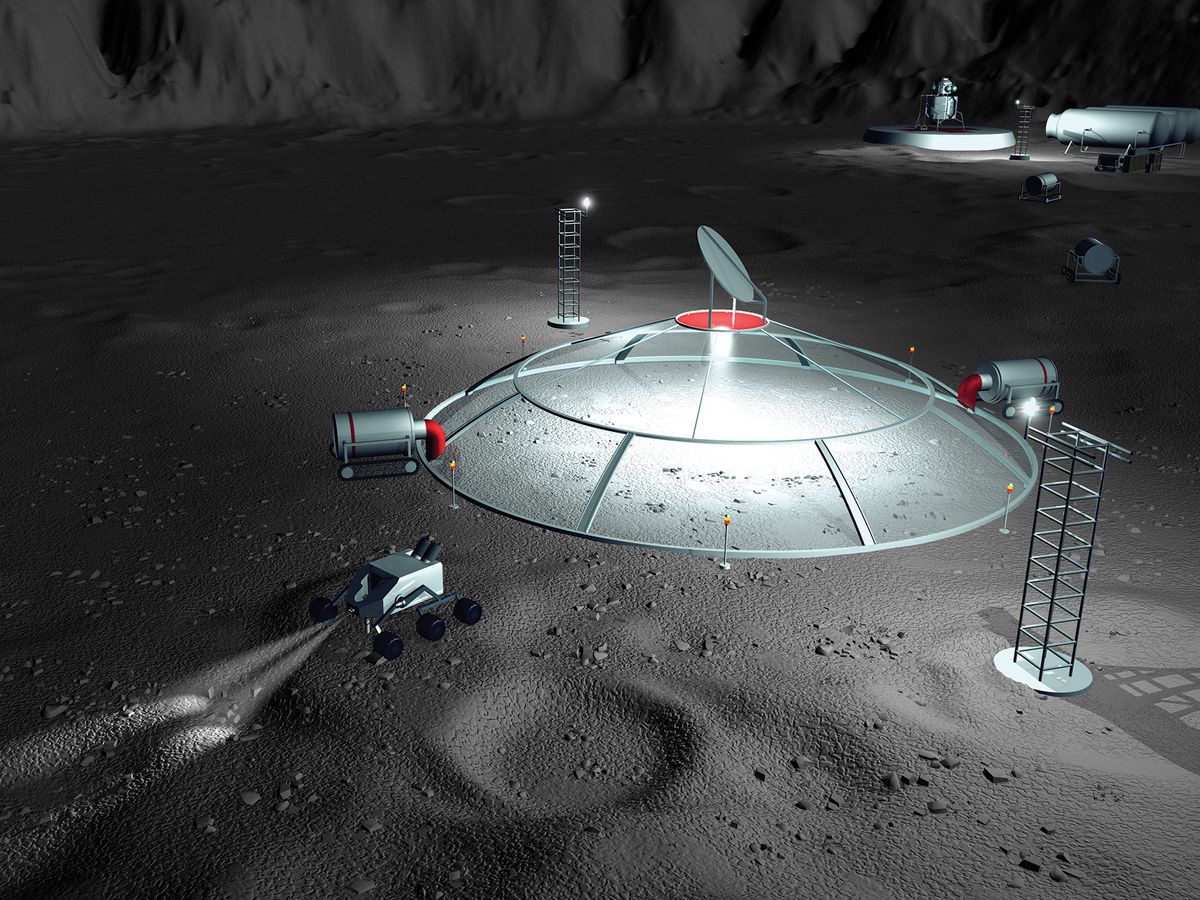

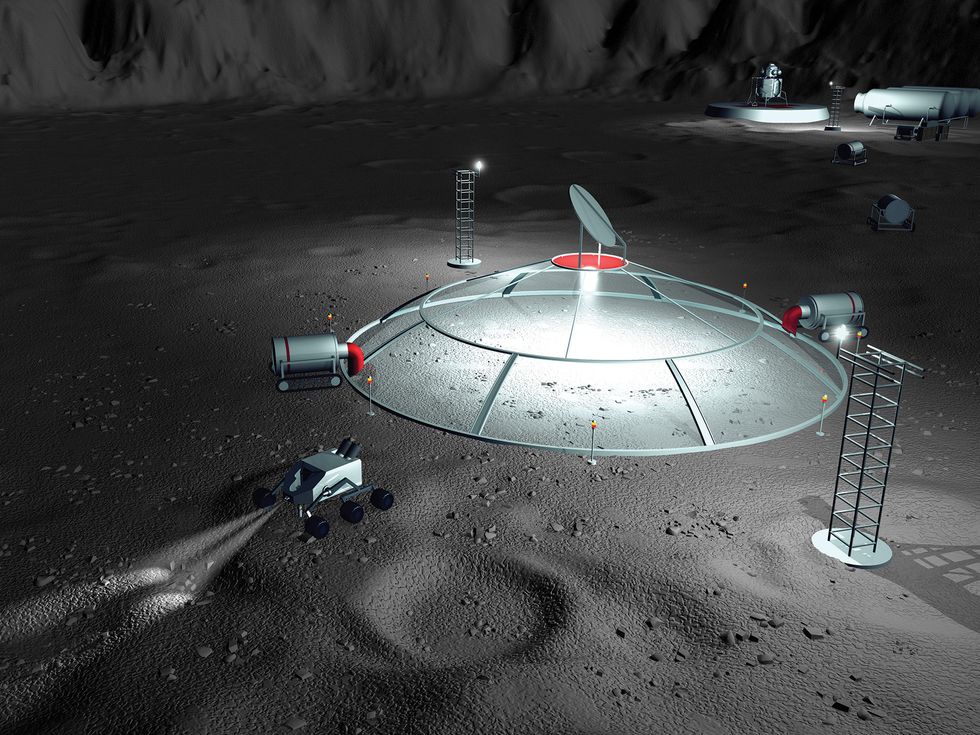

Squeezing Rocket Fuel From Moon Rocks

Here’s how lunar explorers will mine the regolith to make rocket fuel

The most valuable natural resource on the moon may be water. In addition to sustaining lunar colonists, it could also be broken down into its constituent elements—hydrogen and oxygen—and used to make rocket propellant.

Although the ancients called the dark areas on the moon maria (Latin for “seas”), it has long been clear that liquid water can’t exist on the lunar surface, where it would swiftly evaporate. Since the 1960s, though, scientists have hypothesized that the moon indeed harbors water, in the form of ice. Because the moon has a very small axial tilt—just 1.5 degrees—the floors of many polar craters remain in perpetual darkness. Water could thus condense and survive in such polar “cold traps,” where it might one day be mined.