A new all-solid-state lithium battery can not only store nearly twice as much energy as a standard lithium-ion battery, but it’s also not prone to catching fire like its present-day, commercial counterparts. The secret behind this novel prototype’s success? Getting rid of one of a battery’s usual electrodes, a new study finds.

Conventional batteries supply electricity via chemical reactions between two electrodes—the negatively charged anode, where electrons flow out of a battery, and the positively charged cathode, where electrons can enter a battery. A typical lithium-ion battery’s electrodes are made of substances whose structures can store and release electrically charged lithium ions. The anode is often comprised of graphite, while the cathode is very often a metal oxide. These electrode materials are coated onto metal foils that collect the generated current—for the anode, this metal is often copper, and for the cathode, aluminum.

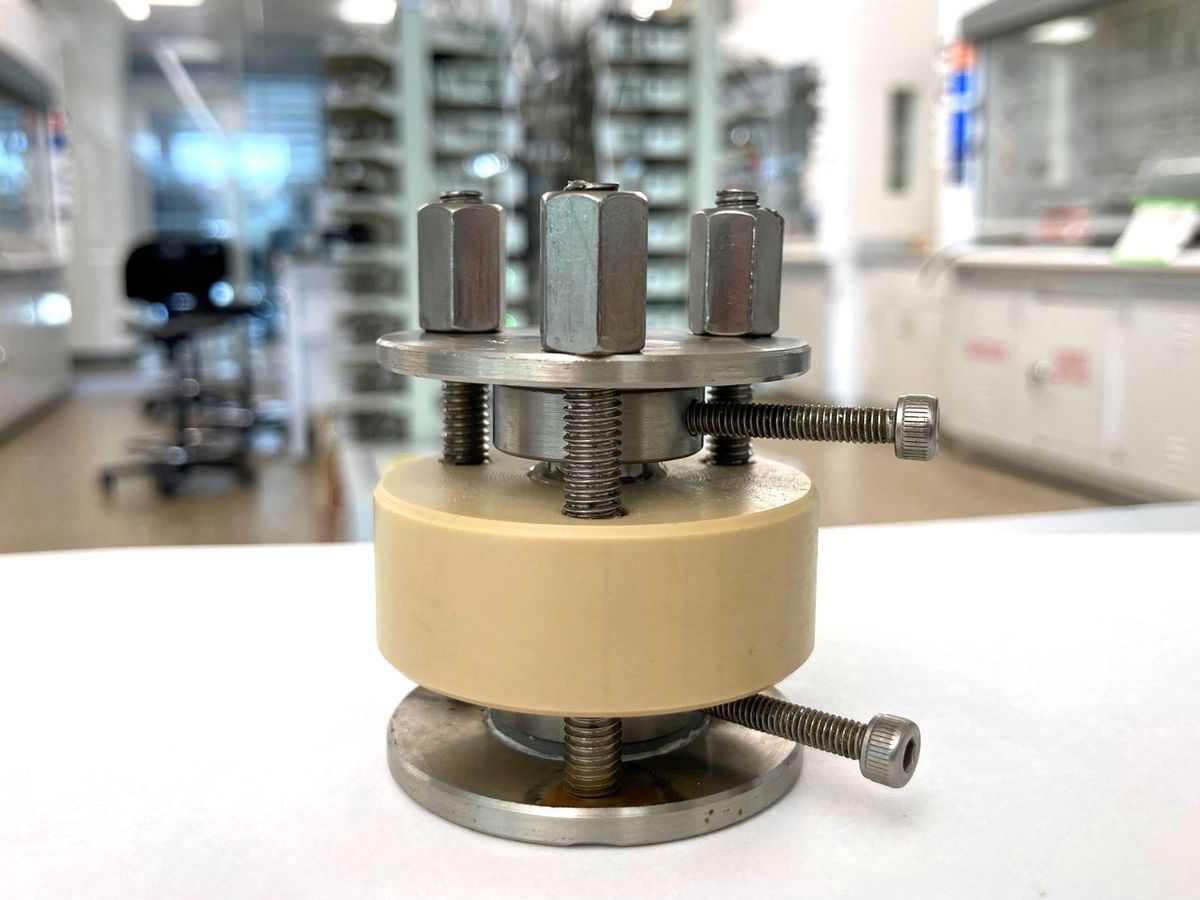

The electrodes in lithium-ion batteries typically interact through liquid or gel electrolytes. All-solid-state batteries instead employ solid electrolytes made of materials such as ceramics.

Solid electrolytes are more compact than liquid or gel electrolytes. This means that all-solid-state batteries can produce more energy than conventional batteries for the same amount of weight or space. In addition, all-solid-state lithium batteries are much safer than their conventional counterparts, which use organic liquid electrolytes that are typically flammable.

Much remains uncertain when it comes to the best way to create a stable, useful, all-solid-state battery. For example, previous research found sulfide-based solid electrolytes could help create batteries that can store a lot of energy. However, the sulfides in these electrolytes can react with both electrodes, generating compounds that impede the flow of electricity within the batteries.

One way scientists have sought to improve all-solid-state batteries is by replacing their conventional graphite anodes solely with a copper-foil current collector. This strategy could significantly boost how much energy these batteries might hold. ”You are in effect eliminating half of the battery’s internal material,” says study senior author David Mitlin, a materials scientist at the University of Texas at Austin. Using less material also reduces their cost, he adds.

However, a key challenge that research on anode-free, all-solid-state batteries has faced is the problem they face going through cycles of discharging and recharging in a stable way. Now, in a new study, researchers show a new coating may overcome this problem.

The scientists experimented with an anode-free, all-solid-state battery with a sulfide-based solid electrolyte. They explored coating its copper current collector with ultrathin lithium-activated tellurium. The aim was to control the way in which lithium metal spread across or “wetted” the copper. They found this new coating helped lithium metal deposit and dissolve from the copper current collector in a thin uniform layer.

Without this new coating, the researchers found the copper foil became covered with irregular microscopic structures during recharging and discharging. These include spiky dendrites that “can, and will, lead to battery short circuits between the anode and cathode, which in turn can cause battery fires,” Mitlin says. They also include lumps of “dead metal” and crusts of honeycomb-like material that impeded the battery’s performance. “It’s like having an engine that is covered by a thick layer of rust on the inside,” he says.

The new battery can hold 72 percent more energy by weight and 95 percent more energy by volume than commercial lithium-ion batteries. The researchers note they could produce the new coating on these copper current collectors using standard fabrication techniques. This could help make it straightforward to scale up the production of these new batteries, they add.

“These findings may provide key missing links for wide-scale commercialization of anode-free and all-solid-state batteries,” Mitlin says.

Still, although this research may solve one critical problem with anode-free all-solid-state lithium batteries, a great deal of development is needed to actually bring them to market, Mitlin cautions. “There is a huge amount of work that is still needed to have anode-free all-solid-state lithium batteries go from lab scale to even prototype scale, never mind to car scale,” he says.

The scientists detailed their findings online 23 February in the journal Advanced Materials.

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.