This article is part of our exclusive IEEE Journal Watch series in partnership with IEEE Xplore.

Smartwatches are growing in popularity thanks to their compact size and wide-ranging abilities, useful for anything from texting to tracking fitness. Yet the convenience of having a smartwatch close on hand (literally) comes with a caveat—namely, that only one hand can be used to input text on smartwatches.

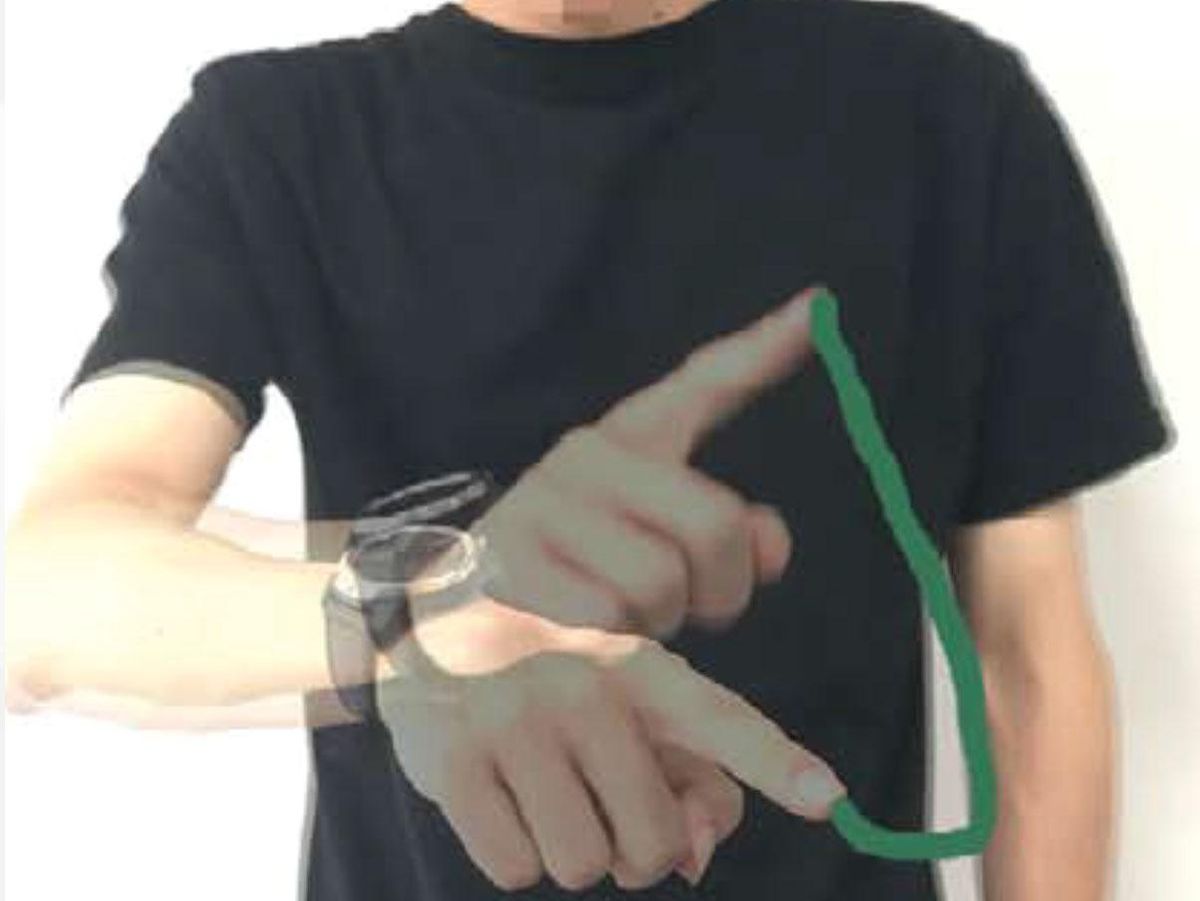

But, one group of researchers in China are pointing to a novel solution, whereby smartwatch users could simply use their finger to write their texts in mid-air in front of them, with no need of a surface. The researchers developed and tested their proposed approach, called AirText, with several volunteers and describe it in a study published November 23 in IEEE Transactions on Mobile Computing.

While speech-to-text input may seem like an obvious solution to the issue of inputting text into smartwatches, relying on audio input involves a number of problems. For example, speech-to-text approaches are not ideal when users are in environments with a lot of background noise, or when users wish to keep the content of their message private from other people within earshot. At the same time, inputting text with just one hand can be slow and cumbersome.

Wei Dong is a professor at the College of Computer Science at Zhejiang University in China. Dong and his colleagues envisioned AirText as a simpler approach and sought to create the app.

“The goal of AirText is to infer the texts written by the fingertip in the air, using only the [inertial measurement unit (IMU)] readings, for example the accelerometers, gyroscopes, and magnetometer, from the smartwatch on the wrist as input,” explains Dong.

However, a major challenge in developing AirText lay in understanding how the user’s wrist movements correspond with the movement of their fingertips as they spell out letters. “[When you are writing] a character in the air using a fingertip, the movements of the wrist and the fingertip are not necessarily the same,” notes Dong. “In fact, as we show in the study, they are quite different.”

To overcome this issue, Dong and his colleagues used a program called Leap Motion, which is able to track the movement of fingers using infrared sensors. Eight volunteers spelled out more than 25,000 characters using five different kinds of smartwatches, while Leap Motion collected data on their wrist and hand movements. The data was then fed into an AI model to infer the relationship between users’ wrist movements and the characters they are spelling out with their fingertips.

The results show that AirText can be effective for writing text in the air, regardless of the type of smartwatch worn or the unique writing style of the user. The volunteers used AirText to achieve an average typing speed of 8.1 words per minute, and their average word error rate ranged from 3.6 percent to 11.2 percent.

To speed up the writing process, AirText can try to predict the word that a user is trying to spell, just like current word prediction software programs on smartphones. Users can tilt the watch to the right or left to select a suggested word, or shake their watch to indicate a backspace.

One limitation, however, is that AirText users must do a short pause in between spelling out individual characters. “This approach slows down the input speed,” says Dong, noting that his team is exploring ways to eliminate the need for this pause.

Dong notes that his team is also interested in commercializing AirText at some point in the future. He says, “We will talk to smartwatch manufactures and smartwatch application developers to see how to apply out technologies to their products.”

Michelle Hampson is a freelance writer based in Halifax. She frequently contributes to Spectrum's Journal Watch coverage, which highlights newsworthy studies published in IEEE journals.