Silicon semiconductors have dominated the electronics industry for the past 70 years, as they are used to build transistors that are found in nearly all electronic devices. But, driven in part by machine learning’s enormous appetite for compute power, a demand for ever smaller transistors is expanding the range of materials that could serve as substrates for transistors and all the components of modern computer chips. Now a team of researchers have found a way to use coal to create ultrathin insulating films that could help launch a new era of semiconductors made with 2D materials.

The study’s focus on coal was no accident. One of the research institutions that participated in the study is the U.S. Department of Energy’s National Energy Technology Laboratory (NETL), which set out to develop advanced, high-value alternate uses for coal, an abundant domestic natural resource that is seeing big declines in use as a fossil fuel. They could hardly have hit upon a more high-tech use than in transistors, electrical components that perform fundamental calculations and are the building blocks for computational power in computer processors. Transistors are made of semiconductors and an insulating material—much like how individual wires in an outlet are wrapped in insulating plastic to prevent interference.

Coal, an abundant U.S. domestic natural resource, is a cost-competitive material and would provide a level of supply-chain security not found in more exotic alternatives.

Today’s semiconductor of choice is silicon. But recently scientists have been looking for materials to replace silicon—potentially with materials like graphene and molybdenum disulfide, which are called 2D semiconductors because they are incredibly flat. That’s because a historical trend that saw the rapid reduction in the size and cost of transistors—known as Moore’s Law—may be nearing its end. It has become increasingly difficult to get silicon, a material whose properties as a semiconductor require all three dimensions, into slices that are thin enough and small enough.

At the same time, powerful machine-learning models require more and more computational power, which on current processors can require enormous expenditures of time and money. OpenAI’s GPT-3, for instance, cost about US $5 million to train. Such intensive resource requirements make it possible for only the largest and wealthiest companies to benefit from machine learning’s advantages.

“So now you have two opposite trends,” said Qing Cao, associate professor of materials science at the University of Illinois Urbana-Champaign and a coauthor on the study. “Moore’s Law is slowing down, but at the same time you have this very fast increased demand on computational power from all these emerging applications.”

2D semiconductors to the rescue

2D semiconductors could help. Graphene, for example, is so thin that a single sheet can be only one atom thick, which allows the length of the semiconductor to drastically shrink as well. Boron nitride is another 2D material—with a bandgap so high it’s experimentally used sometimes as an insulator. But the relative dearth of insulating materials to pair with may even be limiting the development of 2D semiconductors.

“I foresee an environmentally friendly, multidisciplinary manufacturing ecosystem must be established in the future. And this technology could potentially become a key enabler.”

—Yuxuan Cosmi Lin, Texas A&M

The insulating materials used with silicon are metal oxides. Two-dimensional semiconductors could also use metal oxides as insulators, but the interface between the two materials becomes a problem—the jagged and uneven surface of the 3D metal oxides forms traps and scattering centers where it meets the smooth, flat surface of 2D semiconductors. These regions could slow down electrons and deflect them from their path.

Researchers have tried creating 2D insulators before as well, but the problem lies in the fabrication process: To make them, scientists apply heat in a vacuum chamber, and the heat causes the insulating materials to crystallize. Boundaries between neighboring crystals act as a pathway through which current can leak in the insulating material—an obviously undesirable effect. Ideally, an insulating material for 2D semiconductors should be amorphous (noncrystalline) and also 2D.

...and coal to their rescue?

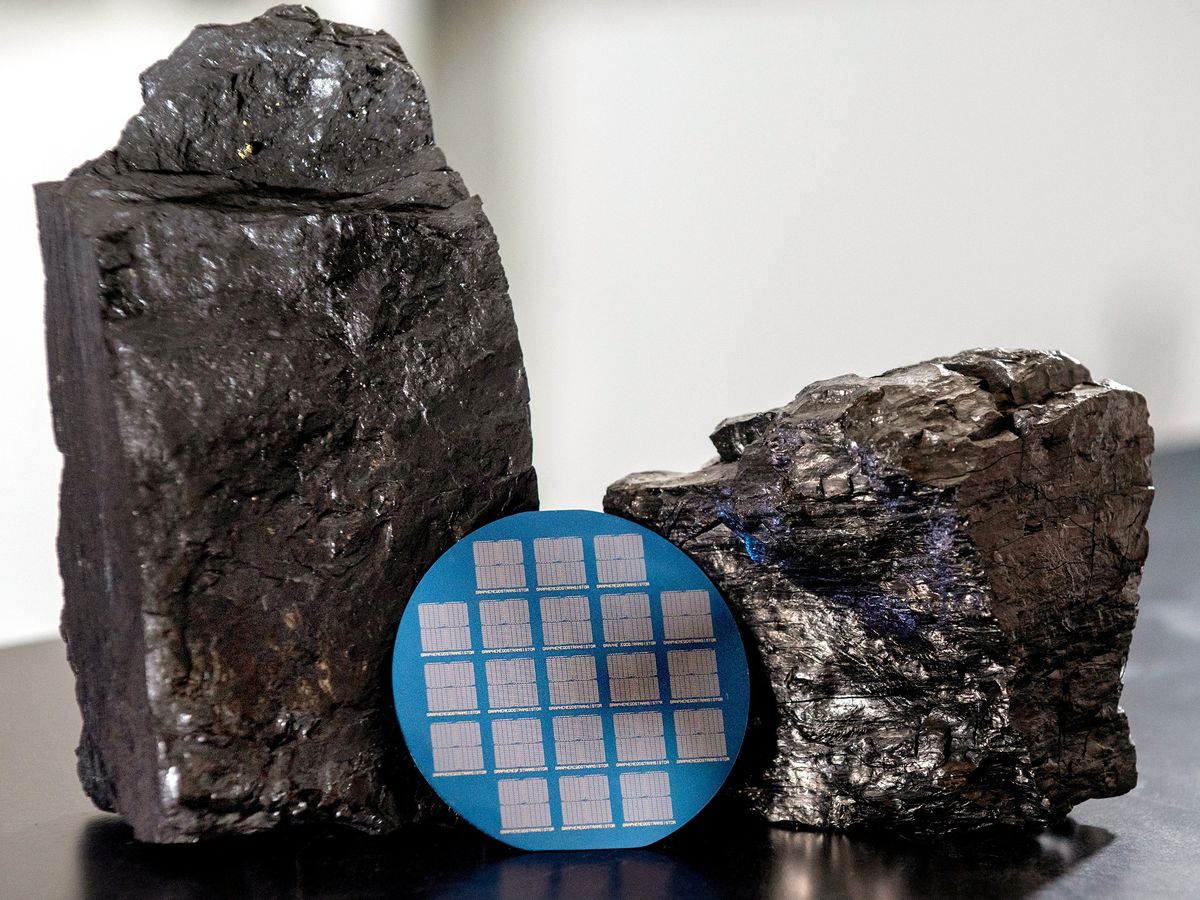

The new material derived from coal happens to be all of these things. When layered with graphene and molybdenum disulfide semiconductors, researchers found drastically improved performance over metal oxide and crystalline 2D insulators. Cao said that the fabrication process was also relatively easy: Blue Gem coal from southeastern Kentucky was ground into a fine powder, suspended in a solution, and deposited into a thin film. Cao said the solution-based process allows for very fine control—researchers were able to achieve consistent layers only 1 to 2 atoms thick.

Congjun Wang, a senior scientist at NETL and coauthor on the study, said coal is an ideal starting material because of its rich nanostructure, which makes it easier to make into an insulator and to scale. Another advantage is that coal, an abundant U.S. domestic natural resource, is a cost-competitive material and would provide a level of supply-chain security not found in more exotic alternatives, Wang said.

The research team also studied the use of the new material as an insulator in memristors, electrical components that can both perform calculations and store data. But Cao said pursuing its use for transistors holds more promise, because currently no other material works well as an insulator for 2D semiconductors.

Yuxuan Cosmi Lin, an assistant professor of materials science at Texas A&M University who is not connected with this research, said that by addressing the insulator problem, this research tackles “one of the most critical remaining challenges” for 2D semiconductor technology.

“I foresee an environmentally friendly, multidisciplinary manufacturing ecosystem must be established in the future. And this technology could potentially become a key enabler,” Lin said.

Future research will focus on methods for scaling up production, Cao said. Interest in the technology is not merely academic. Taiwan Semiconductor Manufacturing Co., the world’s top producer of advanced processors, was involved in the research, showing interest in exploring the possibility of introducing 2D materials into their products in the future.

The researchers’ study appeared last month in the journal Communications Engineering.- New Metal-Air Transistor Replaces Semiconductors - IEEE Spectrum ›

- The Transistor of 2047: Expert Predictions - IEEE Spectrum ›