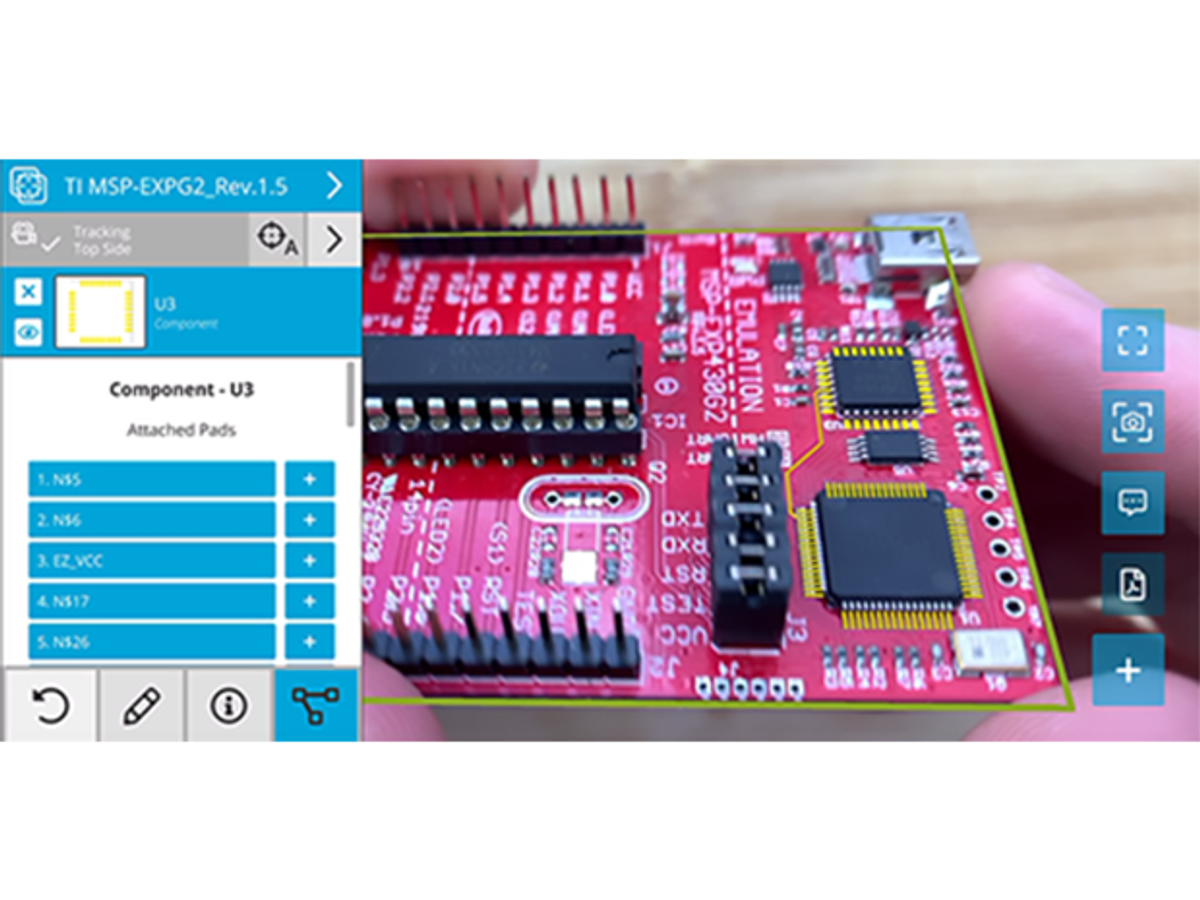

inspectAR is an electronics productivity tool uniquely adapted to lab bench work. By separating a circuit board layout into an AR object consisting of nets and components, anyone who works on a circuit board physically can instantly connect to the expertise of the PCB designer.

Previously, while testing PCBs, you had to switch between circuit diagrams, pin assignments, data sheets and a prototype. Now, by clicking on a component you're brought to its datasheet, supplier information, and a design-specific pinout. A complex net, such as 'GND' on a 12-layer board can be reduced to a set of probeable points, even if a test point was not configured in the design. In the case of fine-pitch components with a small distance between their pins, counting to the pin to-be-measured is error-prone. This first-in-market technology simplifies the analysis and repair of hardware products through augmented reality.

inspectAR overcomes the barrier of using software to interpret a design in the real-world by using a camera and image calibration to PCB manufacturing files (Only a mobile phone or external webcam is required).

Whether for tele-engineering, remote design collaboration, co-debugging, inner layer visualization, instant component lookup, net searching while in the lab, or easier-than-ever work instruction diagrams, inspectAR helps the modern hardware teams of today turn their PCB into a live and interactive, model-based piece of documentation once it comes back from the factory tomorrow.

Click Here to learn more.