Japanese researchers have developed a haptic device that attaches to a person's hand and can simulate the softness of different materials by producing realistic tactile sensations on individual fingertips. According to the researchers, the device could serve as a training tool, helping medical students become skilled in exams that involve feeling parts of the body with the hands. One particular application, they say, would be teaching students how to palpate breasts when looking for lumps.

The researchers, from Gifu University in Japan, call their invention a "multi-fingered haptic interface robot," and they presented it yesterday at the IEEE International Conference on Robotics and Automation (ICRA) in Hong Kong.

Haptics technology has been improving over the years, but simulating touch is still a tricky thing. In particular, simulating the softness of objects has proved a big challenge, because our fingertips are very sensitive and produce nuanced sensations that are hard to replicate.

Conventional haptic devices convey softness by cleverly constraining the motion of fingers and hands. Typically, you operate such devices while looking at virtual objects on a screen or through VR goggles, and if you poke a soft object, the device will let your fingers move a bit into the object before it starts pulling them back, emulating the elasticity of the material.

The Japanese researchers say there's a difference between experiencing a force with your finger and experiencing the sensation of a soft touch. They explain that this sensation is primarily due to cutaneous signals generated when the skin on our fingertips deforms, and this is the phenomenon they wanted to emulate.

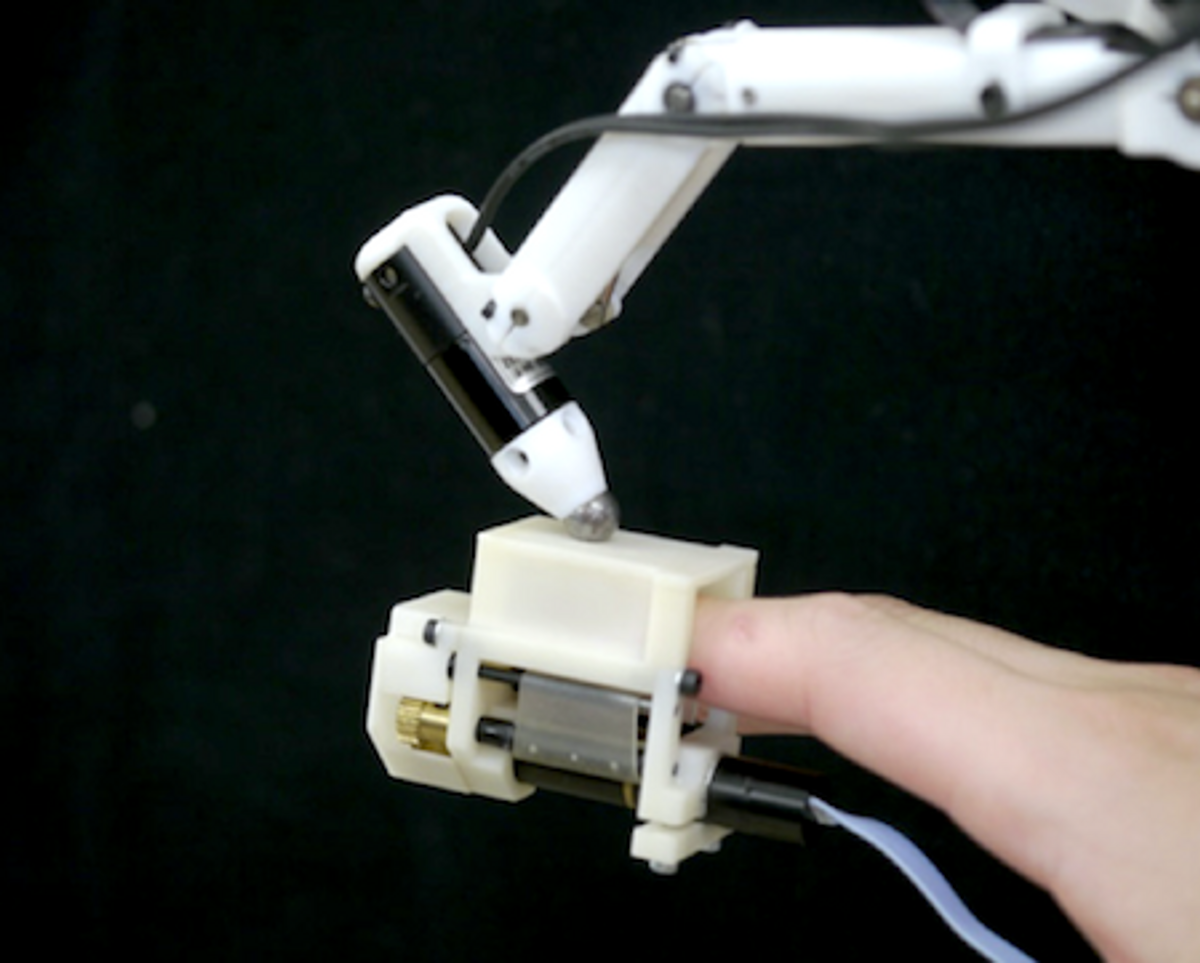

Their device consists of a five-fingered haptic hand connected to a robot arm [photo, right], a design similar to previous haptic systems. The innovative part of their device is the mechanism that comes into contact with the fingertips. This mechanism uses a thin, flexible sheet of a material known as hyper-gel, which has some properties similar to human flesh.

To simulate softness, the sheet of gel is stretched by two tiny rollers with a gap between them, so that a strip of gel is suspended in the air. Your finger rests on this strip. By using a motor and a set of gears to move the rollers, the tension on the strip of gel can be increased or decreased. Increasing the tension (pulling the strip tighter) makes it feel harder under your finger, while decreasing the tension (letting the strip get looser) makes it feel softer [see diagram below].

The researchers say other groups have also developed fingertip haptic systems that can simulate softness, but these systems allow users to "touch" objects of only certain sizes and shapes, and in some cases they had to be calibrated based on physical parameters of each user's fingers. These limitations made them unsuitable for medical training.

They add that commercially available artificial body parts, like breast models made of silicone [pictured below, left], are of limited use as well, because if you're teaching students how to locate lumps, for example, you will need many different models of different sizes and with lumps in different places.

The advantage of their device is versatility. In a simulation, you can have a virtual human body that you can constantly change to create new challenges for the students.

The researchers performed several experiments with their device. In one test, they asked volunteers to feel the softness of a silicone breast model with their fingers. Next, the volunteers used a conventional haptic system that simulated the softness of the breast model. Finally, the volunteers used the newly developed device, which also simulated the softness of the breast model, using the hyper-gel mechanism.

The volunteers reported that using the new system is "similar to the experience of touching a real object," and it's significantly better than the conventional haptic device.

The researchers plan to conduct more experiments, and hope that their hardware will prove accurate enough that it can one day be used to replace humans and animals for significant portions of medical training, mitigating issues of availability and ethics and becoming a valuable tool for training future physicians in the use of touch.

"Softness Display by a Multi-Fingered Haptic Interface Robot," by Takahiro Endo, Satoshi Tanimura, Yuta Kazama, and Haruhisa Kawasaki from Gifu University was presented on Monday at ICRA 2014.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.

Erico Guizzo is the Director of Digital Innovation at IEEE Spectrum, and cofounder of the IEEE Robots Guide, an award-winning interactive site about robotics. He oversees the operation, integration, and new feature development for all digital properties and platforms, including the Spectrum website, newsletters, CMS, editorial workflow systems, and analytics and AI tools. An IEEE Member, he is an electrical engineer by training and has a master’s degree in science writing from MIT.