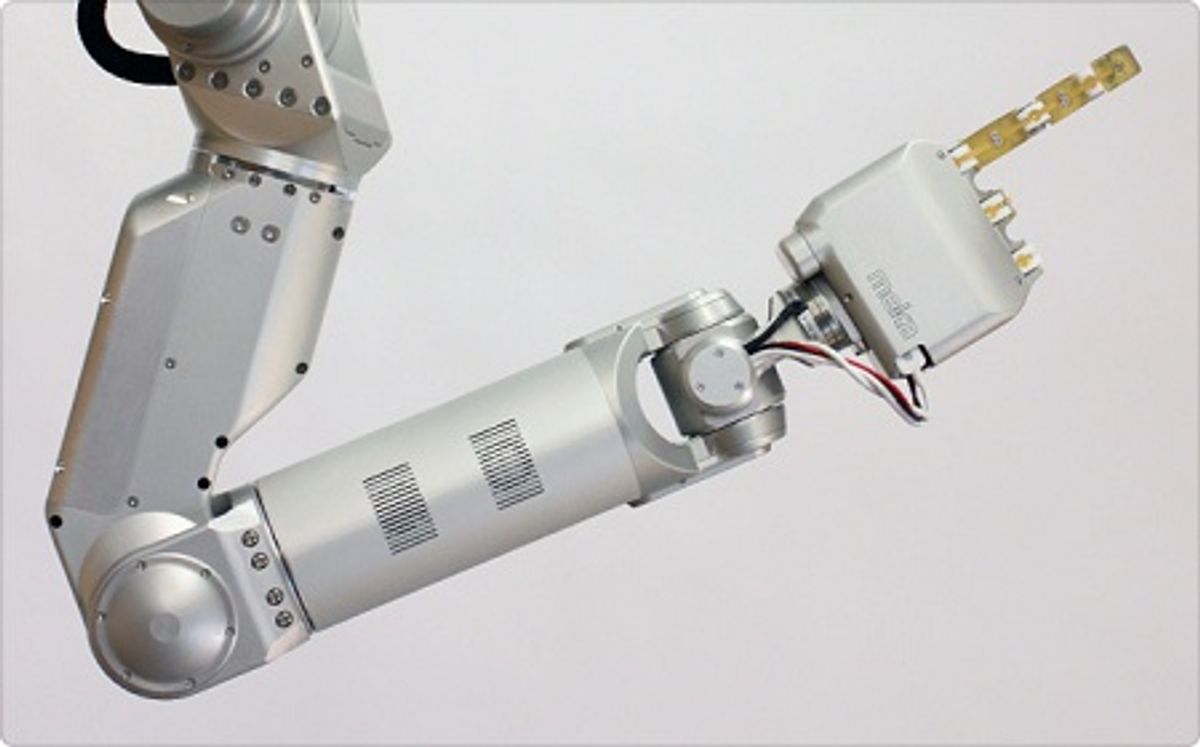

Last Thursday, tech website Xconomy hosted a forum on "The Future of Robotics in Silicon Valley and Beyond." We were there, of course, and so were a lot of other famous robotics people, including Aaron Edsinger of Meka Robotics, who had an announcement to make: an entirely new company called Redwood Robotics, a joint venture between Meka Robotics, Willow Garage, and SRI International.

While Redwood has apparently been in the works for about a year, Edsinger wasn't ready to commit to much as far as what the new company will actually be working on. Here's what we know:

Redwood will be building the "next generation arm" for robots. Edsinger wants to create an arm that does for robotics what the Apple II did for computers: get the hardware out of factories and into homes. In other words, something that's simple to program, inexpensive, and safe to operate alongside people.

Specifically, they'll be working on a "new type of device" with "new types of interfaces," providing "product solutions for integrators, developers, and enterprise customers" who (we'll have to assume) will then sell the arms with software or firmware to end users.

Long term, Redwood wants to be the "arm merchant for emerging personal and service robot markets." So, when you buy your robot butler in a few years, it'll be from some company that isn't Redwood, but Redwood hopes it will supply that robot's arms.

Redwood Robotics isn't the only company that's working on low-cost robot arms. The other big name in this space is Heartland Robotics, a stealthy venture-backed startup founded by Rodney Brooks. Last we heard (December 2010), Heartland was working on a human-safe robot for industrial assembly and packaging that reportedly would cost less than US $5,000:

Visitors to Heartland describe a robot that looks like a human from the waist up, with a torso; either one or two arms with grippers; and a camera where you might expect the head to be. The robot is on a rolling base rather than legs; it can be moved around but doesn’t move autonomously. The arm and gripper can be quickly trained to do a repetitive task just by moving them, no software code required.

We don't know a heck of a lot about either of these companies, but on the face of it, there seem to be two major differences. First, Redwood isn't offering a platform to the end user: they don't seem interested in providing any additional hardware (like a vision system) or even much in the way of software. Redwood just wants to sell arms to people, whereas Heartland is looking to sell an entire functional robot as a drop-in replacement for assembly line workers.

Second, Heartland is targeting industrial markets, while Redwood seems to be focused on personal and service robotics. This could be because Redwood doesn't want to get in the way of a company with $32 million in venture backing and a bunch of big names on board, or it could reflect a fundamental difference in the hardware, or business model, or both. In any case, we'll just have to wait and see with these two, and when we know more, you'll be the first (or, well, second) to hear about it.

[ Redwood Robotics ] via [ Xconomy ] and [ Hizook ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.