Metamaterials are moving on from being merely laboratory curiosities in which objects can be made invisible. They are now reaching the commercial-applications stage—in one example, as the basis of new antenna technologies for mobile phones that are much smaller than earlier generations, but still provide the same signal coverage.

There is a subset of metamaterials known as magnetic metamaterials; these exploit the propagation of electromagnetic radiation, surface plasmons, and spin waves, all of which are properties critical to a new generation of electronics. The development of these materials has been somewhat limited by the fact that the magnetic nanopatterns on them must be fabricated through conventional lithography or ion radiation processes, both of which are irreversible.

Now an international research team led by researchers from the CUNY Advanced Science Research Center (ASRC) in New York City, and the Politecnico of Milan, in Italy, has developed a new process for fabricating these magnetic nanopatterns that allows them to be reconfigured so that their properties can be programmed and reprogrammed on demand.

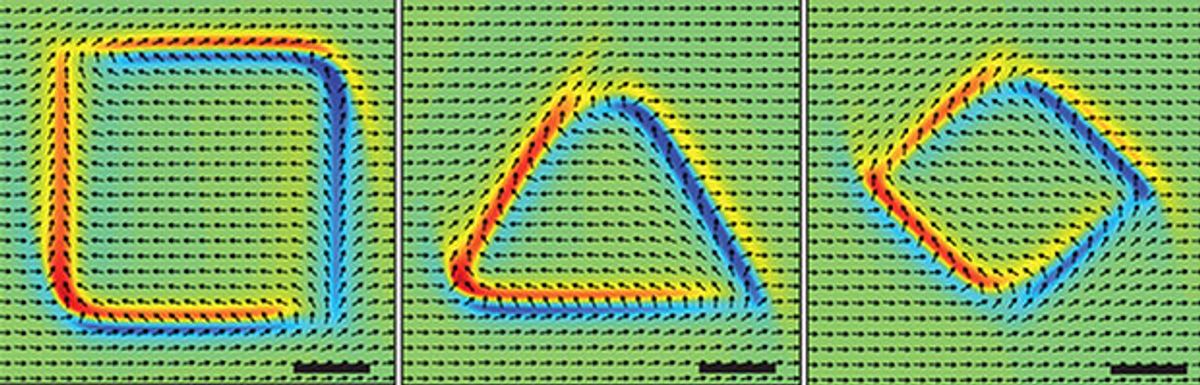

The process they have come up with, which is described in the journal Nature Nanotechnology, is based on thermal scanning probe lithography. A hot nanoscale tip provides localized field heating and then cooling in antiferromagnetic and ferromagnetic thin films. This nanoscale probe essentially aligns the spins in the material in any direction and does so with nanoscale resolution.

“The proposed technique is straightforward and combines the full reversibility and stability of exchange bias, as the same pattern can be written and reset many times, with the resolution and versatility of scanning probe lithography,” said Elisa Riedo, a professor of physics with the ASRC’s Nanoscience Initiative, in a press release. “In particular, this work demonstrates how thermal scanning probe lithography is gaining momentum as a key nanofabrication method for the next generation of nanodevices, from biomedical sensing to sprintronics.”

In the research, the scientists fabricated channels in the material in which spin waves can propagate. Spin waves are like waves of magnetization that are capable of tipping an electron’s spin to change its angular momentum. This is essentially another approach to “spintronics” in which both the spin and the charge of an electron are used, instead of just the charge as is the case with electronics.

The researchers believe that this technique will usher in a new generation of magnetic metamaterials that have both finely tuned magnetic properties and reconfigurable device architectures.

Riccardo Bertacco, a professor with the Politenico of Milan, added:

“Equally promising is the creation of structures with high response to external magnetic fields, as they can be used as sensors in new architectures of spintronic devices. The potential target market for these devices is extremely large—especially with the advent of the age of the ‘Internet of things’—in which every object has a growing need for integrated sensors and computational capacity.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.