Nanomaterials are increasingly viewed as important ingredients in artificial muscles meant to power different types of robots. Carbon nanotubes have been proposed as well as graphene.

Now researchers at North Carolina State University (NCSU), in Raleigh, have developed a technique for embedding nanoparticles of magnetite—an iron oxide—into a polymer so that when the material comes near a magnetic field the polymer moves. The researchers believe that the nanoparticle-studded polymer could lead to a method of remotely controlling so-called “soft robots” whose flexible components allow them to move around in tight spaces in a manner reminiscent of octopodes.

In research described in a paper published in the journal Nanoscale, the NCSU researchers describe a process that starts with dispersing the nanoparticles in a solvent. Next, a polymer is dissolved into the mixture and the resulting fluid is poured into a mold. Then a magnetic field is applied that arranges the magnetite nanoparticles into parallel chains. Once the solution dries in the mold, the chains of nanoparticles are locked into place.

“Using this technique, we can create large nanocomposites, in many different shapes, which can be manipulated remotely,” said Sumeet Mishra, lead author of the paper, in a press release. “The nanoparticle chains give us an enhanced response, and by controlling the strength and direction of the magnetic field, you can control the extent and direction of the movements of soft robots.”

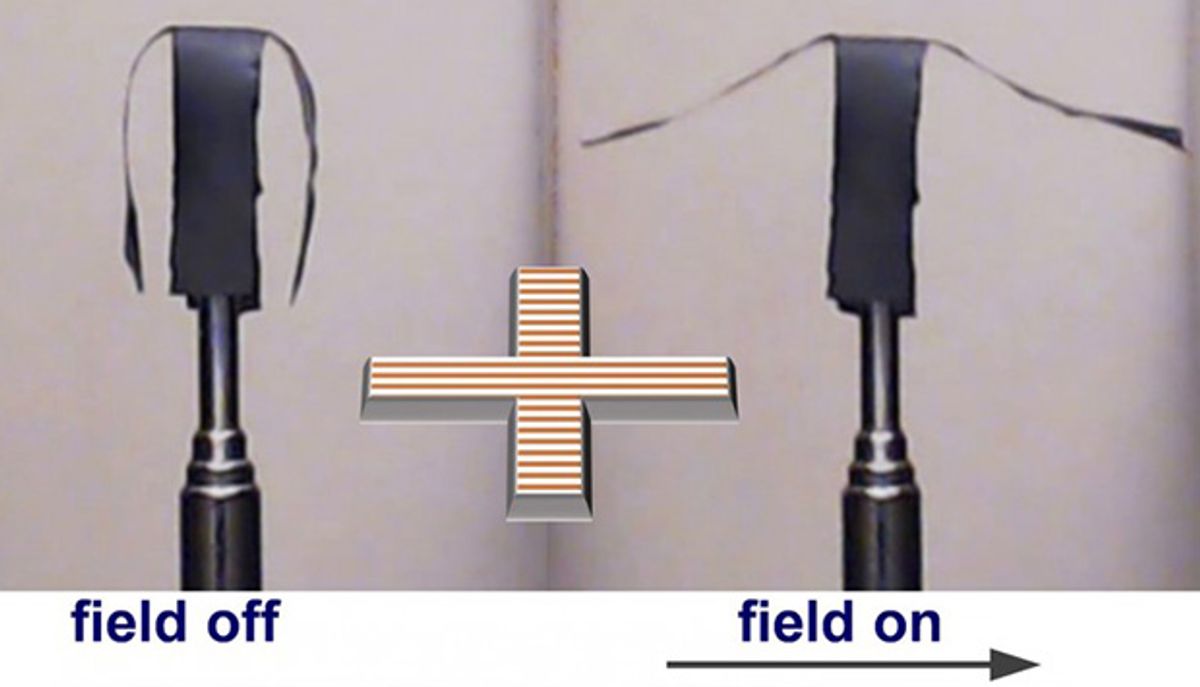

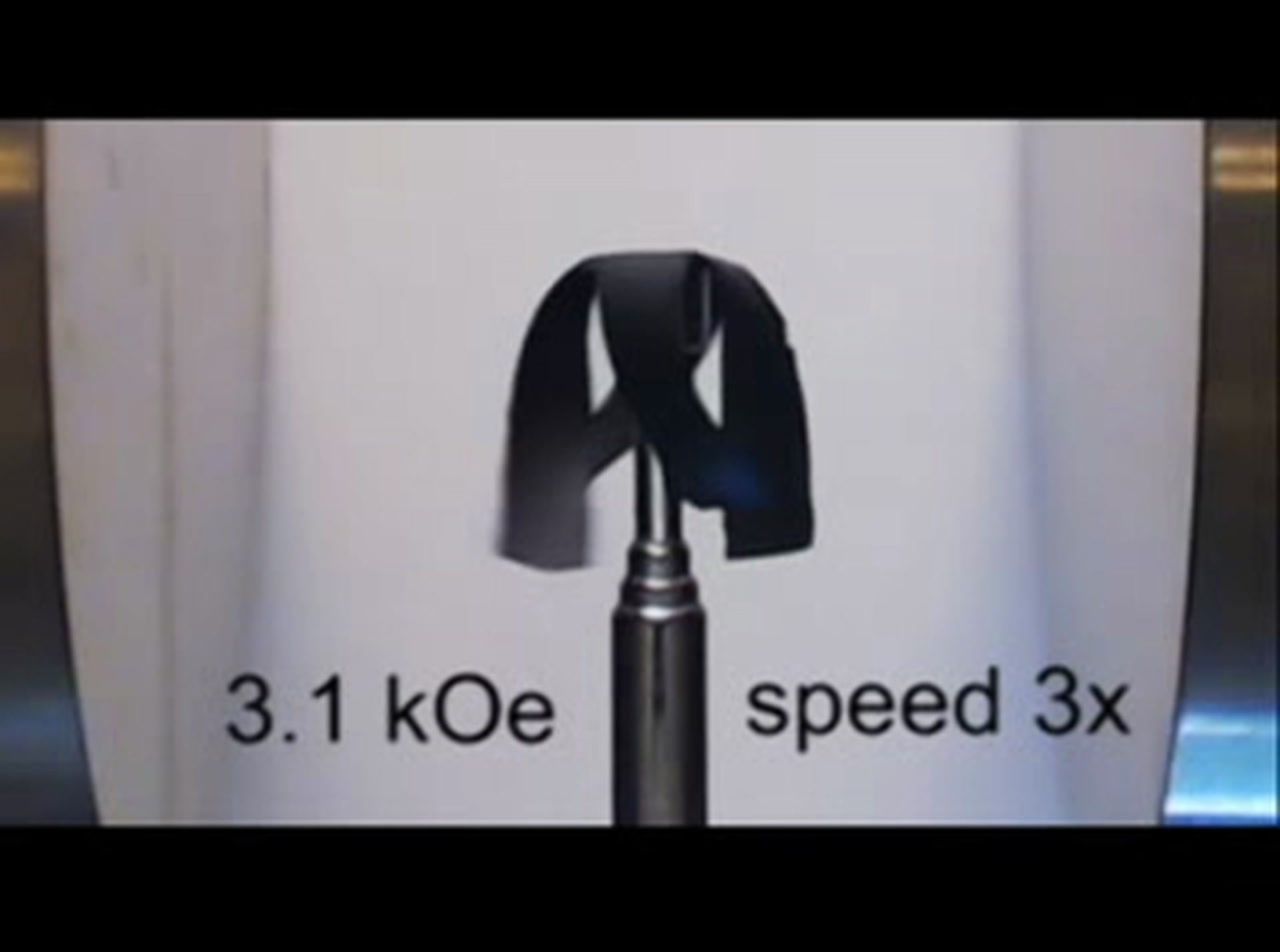

You can see the movement of the polymer under the influence of a magnetic field in the video below.

The phenomenon that causes the polymer to react so strongly to the magnetic field is something called magnetic anisotropy; it makes the material’s magnetic properties directionally dependent. This is achieved by assembling the nanoparticles into chains.

“The key here is that the nanoparticles in the chains and their magnetic dipoles are arranged head-to-tail, with the positive end of one magnetic nanoparticle lined up with the negative end of the next, all the way down the line,” said Joe Tracy, an associate professor at NCSU and corresponding author of the paper, in the press release. “When a magnetic field is applied in any direction, the chain re-orients itself to become as parallel as possible to the magnetic field, limited only by the constraints of gravity and the elasticity of the polymer.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.