Last year, perovskites established themselves as the “next big thing” in photovoltaic materials, with energy conversion efficiency numbers reaching as high as 20 percent.

Now researchers at the University of Wisconsin-Madison have demonstrated that perovskites can produce high-efficiency, ultra small lasers.

“While most researchers make these perovskite compounds into thin films for the fabrication of solar cells, we have developed an extremely simple method to grow them into elongated crystals that make extremely promising lasers,” said Song Jin, a professor at the University of Wisconsin-Madison, in a press release.

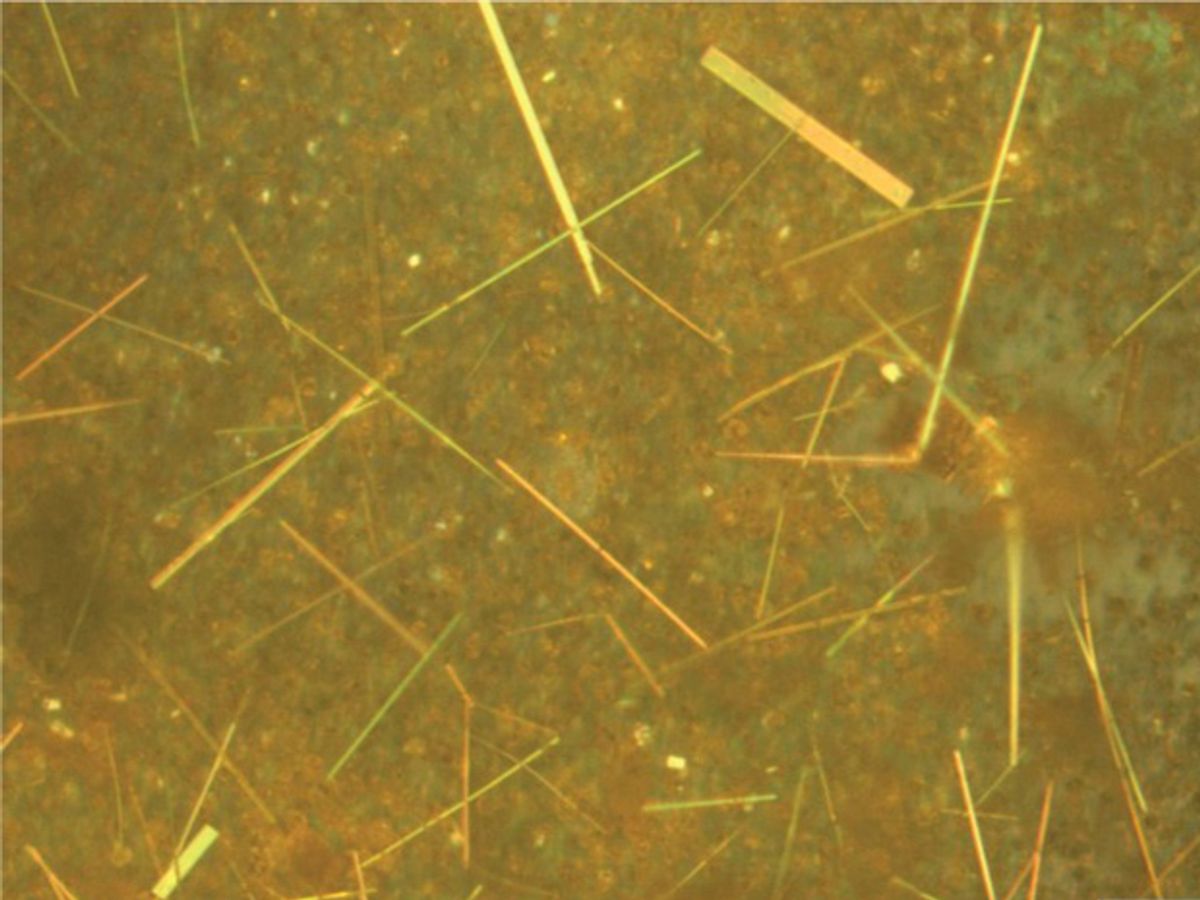

In research published in the journal Nature Materials, Jin and his colleagues produced the perovskite material in a simple chemical solution process that resulted in nanoscale rectangular crystals of the perovskite that, because of their scale and dimensions, are dubbed nanowires.

“The single-crystal perovskite nanowires, grown from solutions at room temperature, are high quality, almost free of defects, and they have the nice reflective parallel facets that a laser needs,” Jin said in the release. “Most importantly, according to the conventional measures of lasing quality and efficiency, they are real standouts.”

In measurements, the nanowire lasers proved to be 100 percent efficient, meaning that every photon they absorbed was used to produce a photon of laser light. According to one of Jin’s collaborators, Ziaoyang Zhu of Columbia University, this level of efficiency is one order of magnitude greater than other nanowire lasers.

“These are simply the best nanowire lasers by all performance criteria, even when compared to materials grown in high temperature and high vacuum,” said Jin. “Perovskites are intrinsically good materials for lasing, but when they are grown into high-quality crystals with the proper size and shape, they really shine.”

In further research, the aim will be to improve the chemical stability of the nanowire lasers and to stimulate the lasers with electricity rather than just light.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.