As demand for renewable energy soars, materials researchers are seeking ways to create more efficient solar cells. Standard crystalline solar photovoltaic (PV) cells produced commercially today typically can boast an 18 to 22 percent efficiency range. However, some researchers have turned their attention to more efficient silicon heterojunction (SHJ) solar cells—the efficiency of which has reached 26.8 percent in the lab. SHJ’s numbers could be boosted further, too.

The effectiveness of SHJ cells relies on the quality of its passivation layer. The passivation layer is a thin coating on the SHJ cell’s surface. As the name suggests, the passivation layer decreases the rate charged particles combine again. As a result, a good passivation layer enables the carriers to boost the cell’s electric current and voltage. And, as experiments have shown, finding ways to improve the passivation layer can also increase a solar cell’s efficiency.

One of the standard methods for depositing passivation layers today—plasma-enhanced chemical vapor deposition—also, however, can damage the substrate itself, says Keisuke Ohdaira, a professor of materials science at the Japan Advanced Institute of Science and Technology (JAIST). So Ohdaira and colleagues have been experimenting with an alternative process called catalytic chemical vapor deposition (Cat-CVD).

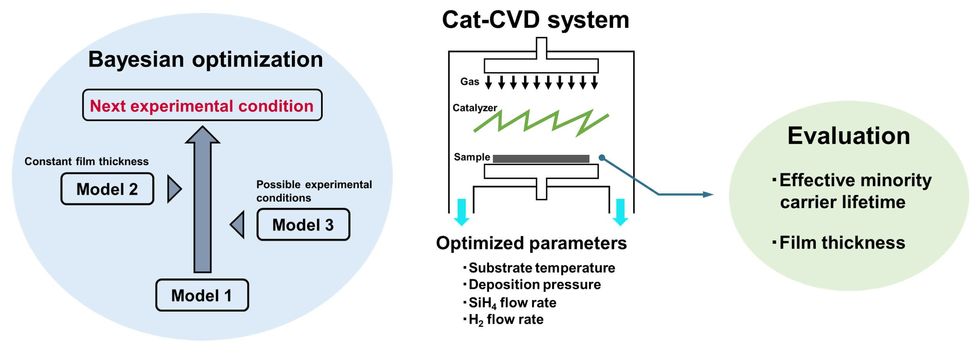

Using Cat-CVD, gas molecules are decomposed by catalytic cracking reactions that enhance deposition to the solar cell without also causing harm to the substrate. Unfortunately, discovering the ideal conditions for Cat-CVD can be very challenging. Many adjustable parameters complicate the process, including tweaks to substrate temperature, gas flow rates, and deposition time.

As a result, because discovering the optimum parameters represents such a time sink, the SHJ solar cell manufacturing process could be stuck in a rut unnecessarily.

Thomas Bayes steps up

To address this challenge, the researchers, working with Kentaro Kutsukake—a researcher in AI and machine learning applications at RIKEN, Japan’s largest national research institute—have come up with a new approach to Cat-CVD. Their scheme is based on a kind of math called Bayesian optimization, which uses probabilistic models to more efficiently discover a set of ideal parameters.

Bayesian optimization (named for the 18th century English statistician Thomas Bayes, whose work is often used today to estimate reliability and possible points of failure in a system) follows a sequential process, says Kutsukake. “We first provide initial data of deposition conditions and their results to the [Bayesian] algorithm,” Kutsukake says. “The algorithm then predicts the output for deposition conditions that have not been evaluated yet, and gives candidates for the next cycle of deposition conditions. We repeat this sequence over and over, feeding the results back into the algorithm until we eventually get the optimal values for the deposition.”

But applying Bayesian statistics blindly to Cat-CVD is not the solution, says Ohdaira. By itself the process might yield proposed experimental combinations of parameters that are unfeasible. It could, for instance, suggest gas flow rates and vacuum chamber pressures that are impracticable, given the low exhaust capacity of the vacuum pump.

To get around these problems, the researchers have implemented a practical optimization approach called constrained Bayesian optimization, which uses three prediction models. So, for instance, one model might optimize carrier lifetime, while another might optimize input gas flow rates, while yet another might filter out unfeasible deposition scenarios. The researchers then aggregated predictions of all three models into an optimization system. When the aim was to maximize carrier lifetime, the researchers fed the optimization system with 14 samples of related deposition conditions and then experimentally measured passivation film performances.

“We achieved high carrier lifetimes after just eight optimization cycles,” says Ohdaira. “And we completed fine-tuning optimization after 20 cycles.” Though the end result of this experiment is not a stunning breakthrough in SHJ solar cells, Ohdaira points out, “It is in developing a new approach to BO that can be applied to several fields requiring complicated material process, including film depositions for semiconductor fabrication, that is valuable.”

The results of the team’s research were published in ACS Applied Materials and Interfaces last month.

Other research teams, it’s fair to note, have also used smart algorithms to improve solar cell efficiency. In 2021, for instance, MIT and Google Brain introduced a differentiable solar cell simulator that yielded results similar to the JAIST method. But, Kutsukake says, the constrained Bayesian approach with Cat-CVD derived their results from real experiments, not computer models. As for the researchers’ next step, it involved constructing an SHJ silicon solar cell using the new Bayesian approach.

UPDATE 27 Mar. 2024: The story was updated to add emphasis to the applications outside of solar PV research and development of the Bayesian optimization process the researchers had developed.

- Nanostructured Silicon Solar Cells Achieve High Conversion Efficiency Without Antireflective Coatings ›

- High-Efficiency Solar Cells Power Satellites—Can They Come Down to Earth? ›