Amid the height of the COVID-19 pandemic, the worldwide semiconductor shortage raised new concerns about counterfeit chips. These include chips that are falsely marketed, misrepresented as recycled, or use old, fake, or just not-quite-right parts.

Now, even as the chip shortage has begun to abate, some researchers are still tracking fakes of one particular type of chip—field-programmable gate arrays (FPGAs)—and working on better ways to identify counterfeits.

FPGAs aren’t new, but they’re important. Their signature feature is that they can be reconfigured post-manufacturing, which makes them incredibly flexible. This flexibility means they’re often found in technology with a direct impact on national security, including satellites, military tools, and aviation systems. As a result, bogus FPGAs are extremely concerning.

“Basically, an FPGA can be a supersimple logic component or get configured as a microprocessor. So having this flexibility adds a great value to FPGA,” explains Alexandro Castellanos, an engineering professor at the University of South Florida. “That’s what makes it so valuable, strategically. An FPGA can take the form of whatever you need in terms of electronics, from simple applications to defense systems to drone control.”

Like other chips, FPGA supplies were impacted by pandemic supply-chain issues. These chips are currently limited and allocated to the largest customers, according to Global Electronics Testing Services, a component authentication service that Castellanos is working with to track FPGAs.

Because FPGAs are not specially manufactured and can be modified after purchase, they can be substituted with other, less-functional alternatives, with sometimes dangerous results. In one prominent example from 2011, the U.S. Navy inadvertently installed a “reworked” Xilinx FPGA in a reconnaissance aircraft that had, at an earlier step in the supply chain, been marketed as new. The Navy blamed the FPGA for the failure of the aircraft’s ice-detection module during a test flight.

“If the FPGA is counterfeit there is a risk that the ‘brain’ is not functioning properly or at full capacity. Another risk of counterfeit FPGAs is, in theory, you could configure or program one to do something very different from what was intended,” said Faiza Khan, the executive director of the Independent Distributors of Electronics Association (IDEA), a trade organization that focuses on the quality of the electronics supply chain, in an email.

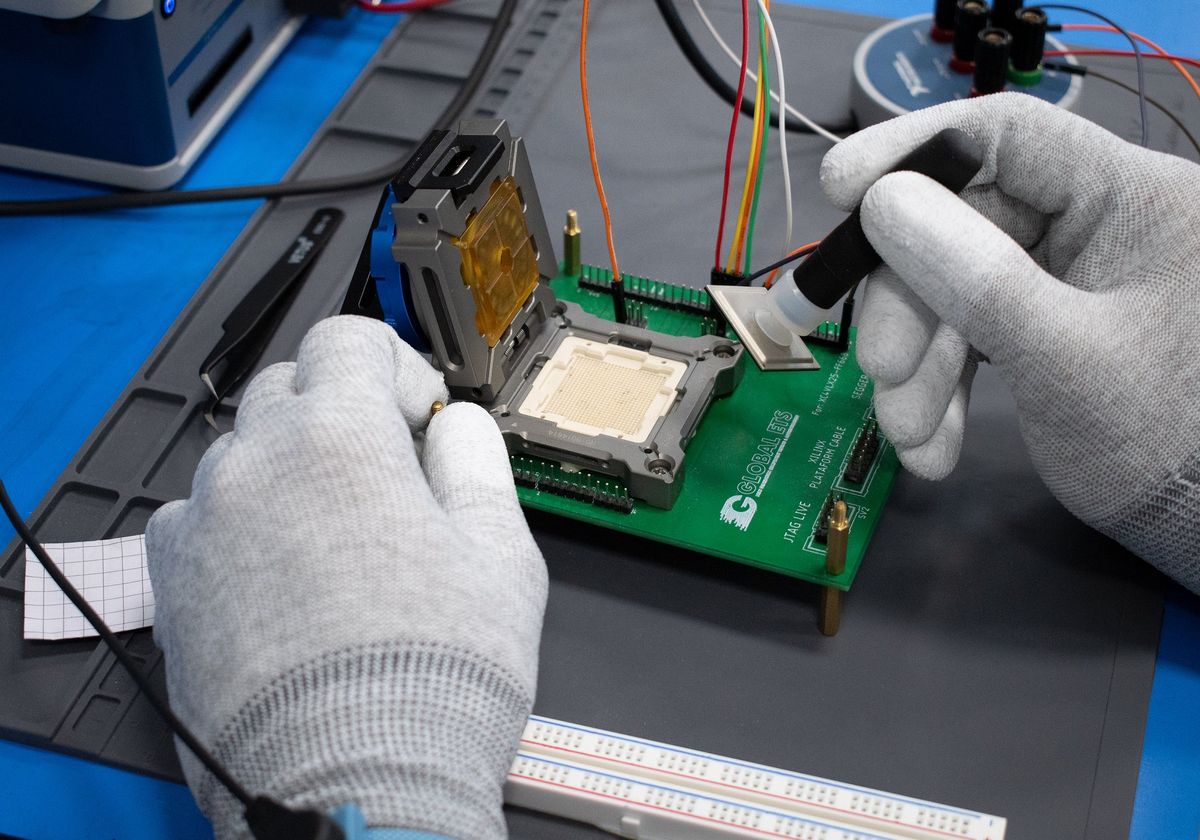

Castellanos, along with another University of South Florida engineering professor, Stephen Saddow, is working with Global ETS on methodologies for investigating potential counterfeit FPGAs. The company is increasingly interested in using AI for this purpose, too.

The methodology can depend on how chips are packaged. Counterfeiters, meanwhile, might remove old markings with sandpaper or microblasting—and detach a chip’s protective cap—to trick buyers. Bar codes, which can be used to confirm the authenticity of a part, might be erased.

“Imagine you’re looking at two identical Honda Accord cars, but the engines and the features inside the engine are completely different,” explains Saddow. “When you look at the car, same color, same model, year, and everything. One engine has been modified and one engine is original—you open the hood and discover they’re completely different.”

ETS’s methodology first involves conducting a visual inspection to look for any hints of resurfacing or remarking. If the chip uses a plastic molding test, the company might examine the chip by using solvents to look for potential signs of resurfacing or remarking. For chips with metal packages, the company deploys scanning acoustic microscopy, which uses reflected sound waves to detect imperfections or oddities. Further steps can include electrical testing, speed and temperature testing, and even decapsulation, in which a chip’s internal structure is exposed for investigation.

Now the company is looking at using artificial intelligence to deal with one of the most difficult problems with identifying counterfeit FPGA: doctored temperature and speed ratings. Traditionally, analyzing these aspects of FPGAs has been expensive.

“An FPGA buyer relies on manufacturer representations regarding operating characteristics such as speed and operating temperature range,” explained John Villasenor, a electrical engineering professor at the University of California, Los Angeles and the codirector of the university’s Institute for Technology, Law, and Policy, in an email. “Counterfeit FPGAs may not deliver the advertised performance, putting at risk the systems in which the counterfeit FPGAs are installed.”

The problem remains difficult to broadly track. Counterfeiters don’t report their numbers, observes Saddow, and companies aren’t likely to open up about the dupes they’ve fallen for.

Of course, Global ETS is far from the only organization focused on the issue, but the company says it has added several new locations in the past several years and seen a surge in business. IDEA has its own guidelines and recommended inspection techniques for dealing with counterfeit chips. The Semiconductor Industry Association, which lobbied for the recent CHIPS and Science Act legislative package, has been monitoring the issue as well.

- Painless FPGA Programming ›

- Chip Hall of Fame: Xilinx XC2064 FPGA ›

- The Hidden Dangers of Chop-Shop Electronics ›

Rebecca Heilweil is a journalist focusing on emerging technology and technology policy. She has written for Wired, the Wall Street Journal, and Slate, among other outlets.

To find her elsewhere: https://twitter.com/rebheilweil