More than two decades ago, organic polymers entered the electronic world, leading to semiconducting organic materials that found applications such as RFID (radiofrequency identification) tags or flexible solar cells.

Now a research group lead by Evandro Castaldelli at the University of Sao Paulo, Brazil, in collaboration with researchers in the UK and France, have identified another class of chemical compound, the more exotic metal-organic frameworks (MOFs) as promising for application in electronic devices.

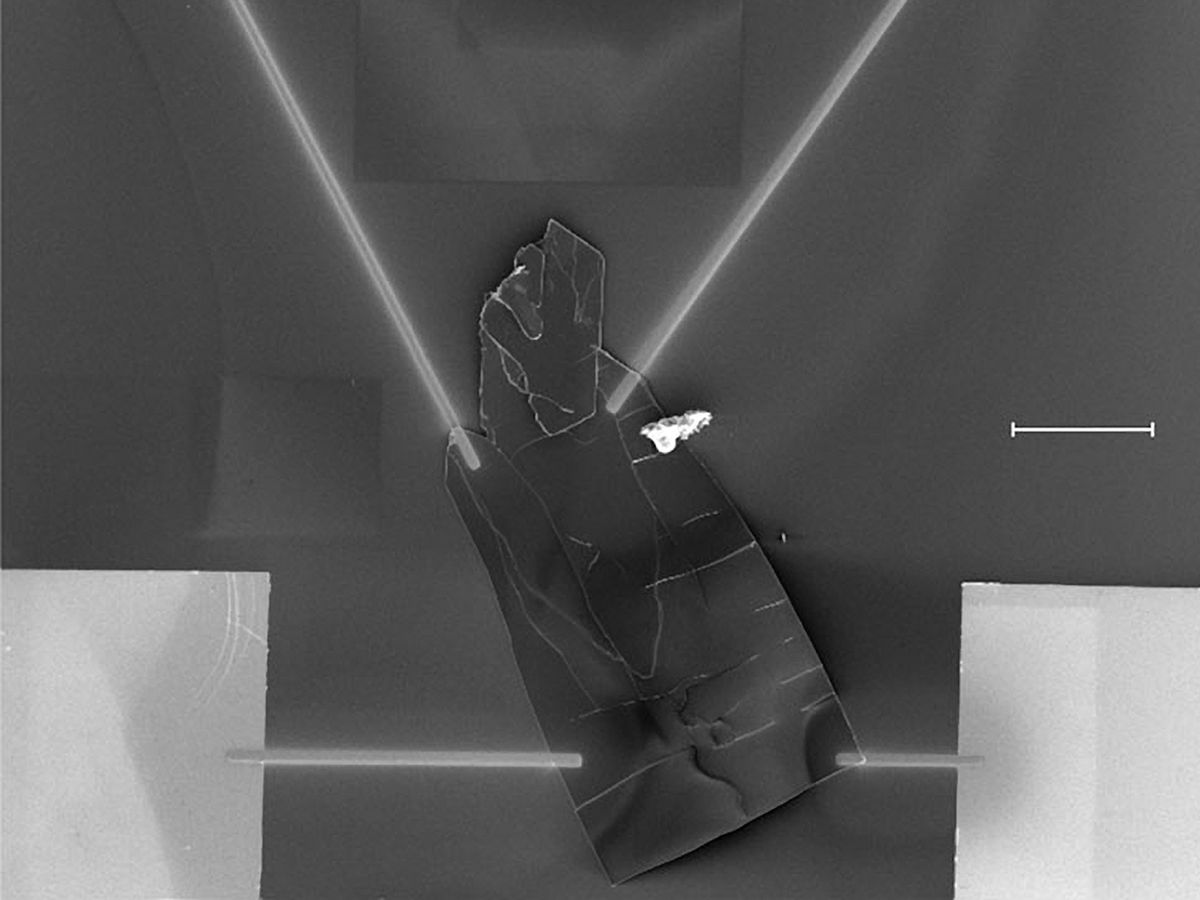

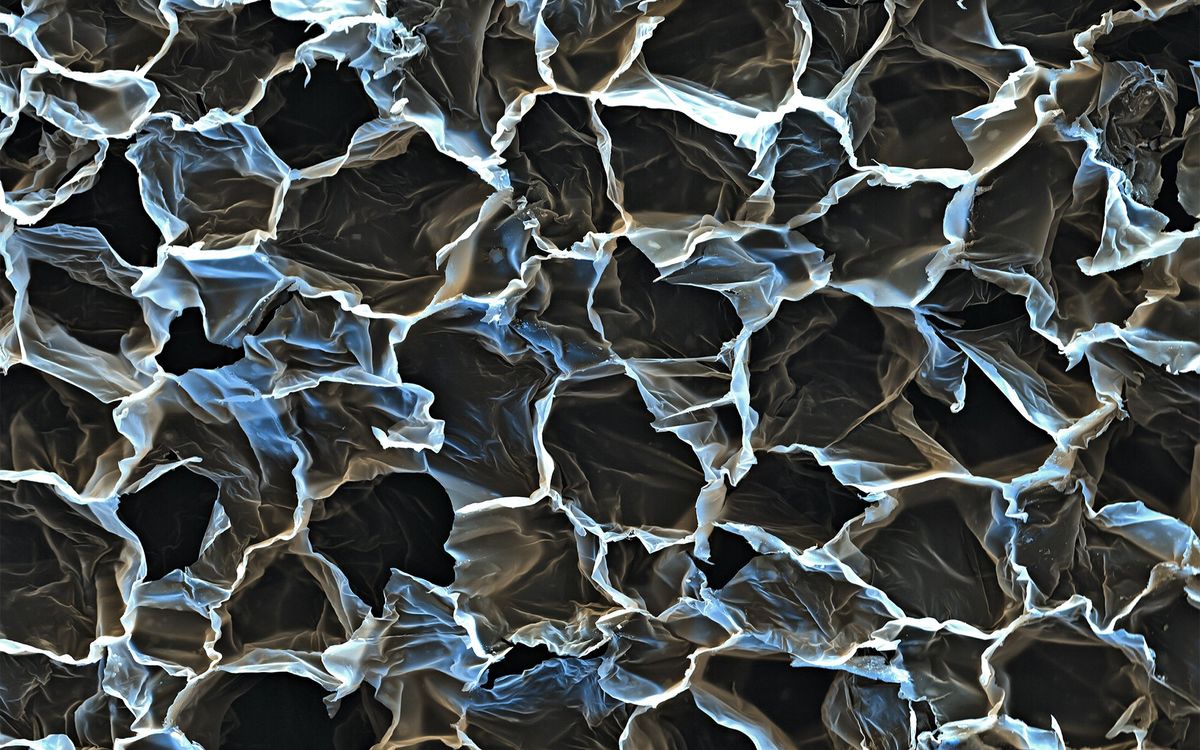

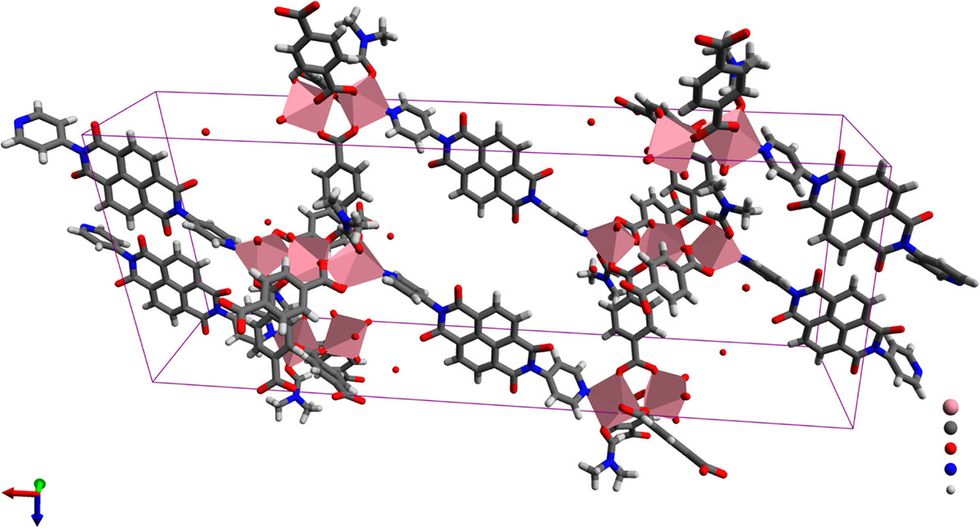

MOFs are crystalline organic-inorganic hybrids with a microporous structure. Because of their large surface area they have come to the attention of the scientific community as a suitable material for storing gases or as catalysts, says Castaldelli, the lead author of a paper just published in Nature Communications.

But there is another aspect that makes these materials unique: it is possible to engineer their properties.

“They inherit the properties of the various compounds that make them up. For instance, you obtain a framework that is magnetic by choosing a magnetic metal center and fluorescent ligands,” explains Castaldelli. “We looked at how these materials could be used in any kind of electronic devices, such as solar cells or transistors that could use semiconductors with MOF properties, and we found that these materials could be a game changer,” he says.

To find the materials that might produce semiconducting properties, the researchers looked at existing organic materials used in current electronics and identified which materials caused the semiconducting properties. “We combined these materials with suitable inorganic ions, and obtained MOFs with suitable electronic properties” says Imalka Jayawardena of the University of Surrey in the UK.

Their research focused on a cobalt and naphtalene diimide metal-organic framework. Besides being an excellent semiconductor it also has an exceptional response to light, an aspect they explored in detail in their research.

“What interests us is not a new device, but a classic photosensor, in which we could combine the MOF properties with electronic properties,” says Castaldelli.

The device would also compete directly with silicon gallium arsenide solar cells and photodetectors. “Gallium arsenide is very expensive, and our devices will be cheaper,” Jayawardena predicts.

The tuning of the properties of these materials might lead to other interesting applications, such as gas sensors. “We can combine the high porosity of these materials with the semiconducting properties for gas detection,” says Jayawardena.

One of the other advantages of MOF materials is that they can readily be created on substrates by printing techniques. “In principle you can apply any of the conventionally used semiconductor clean room applications; you can control the structure and chemistry during growth of the materials,” Jayawardena adds.