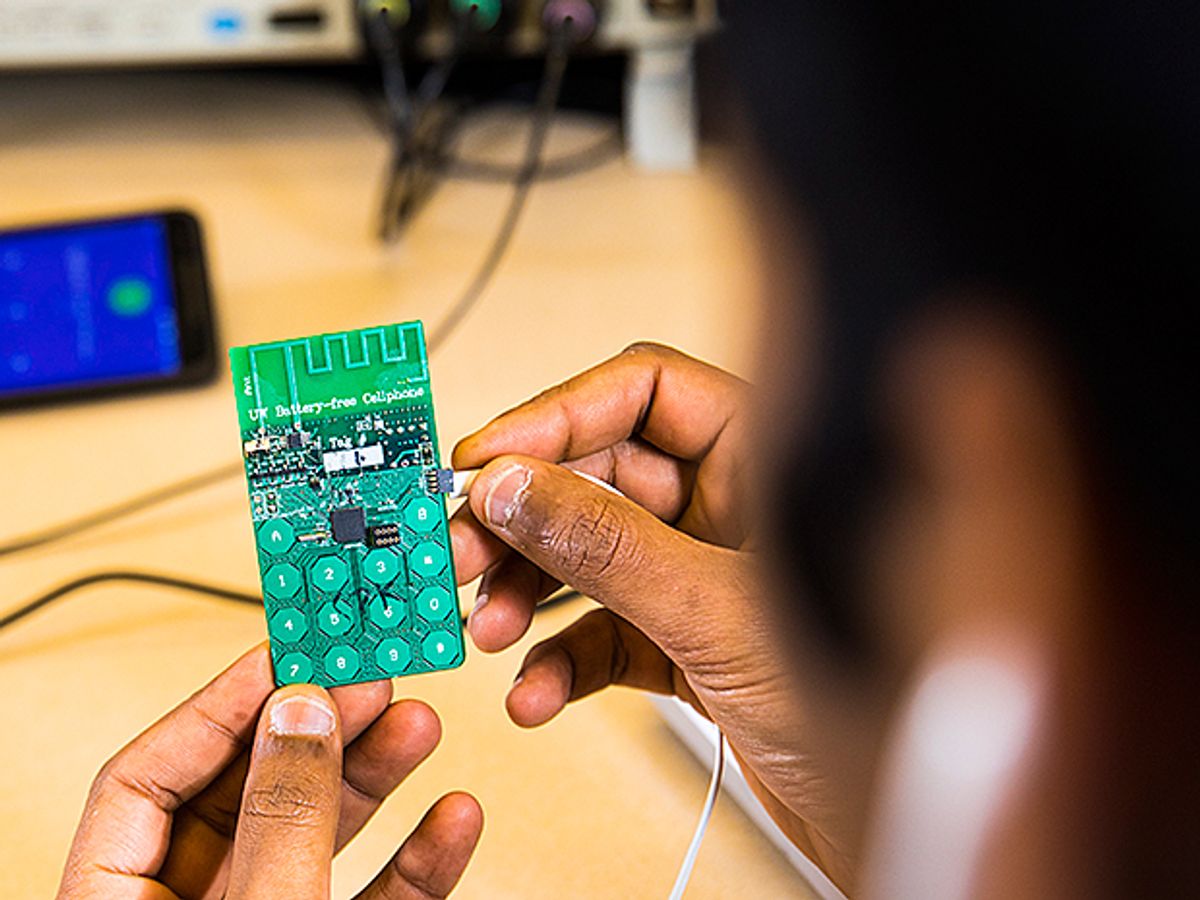

THE INSTITUTEIs the future for smartphones battery-free? That's one question The Institute asked IEEE Member Vamsi Talla, who recently finished building the first battery-free cellphone with fellow researchers at the University of Washington, in Seattle.

The project is supported by a Google Faculty Research award in addition to three U.S. National Science Foundation grants—which totaled more than US $2 million.

The team began working on the phone last year while Talla was earning his Ph.D. in electrical engineering, which he completed this year. He is now the CTO of Jeeva Wireless, a Wi-Fi technology company in Seattle.

Right now the phone only can make voice calls and dial an emergency operator. Talla says the phone could be especially useful for people living in developing countries who don't have a way to charge a phone.

In this interview, Talla shares why his team is building the battery-free phone and what the future is for the technology.

How does the battery-free phone work?

The phone receives power from sunlight or RF waves sent from a nearby base station, a fixed point of communication for customer cellular phones on a carrier network. With a technique called backscattering, the phone can make a voice call by modifying and reflecting the same waves back to the base station.

We also were able to make Skype voice calls, proving that the prototype—made of commercial, off-the-shelf components—can communicate with a base station and applications like Skype. The phone consumes only 3 microwatts of power—which is about 10,000 times less than what a current smartphone consumes.

What are the benefits to the phone being battery-free?

For one, users can dial the number for the emergency operator without any battery power. In fact, you can call anyone with zero power. This technology is especially useful in developing countries, where there aren't many reliable sources to charge a device.

We created our phone with a simplistic design and made it significantly cheaper than current smartphones on the market—which means it could be accessible to more people.

What we're working on next is enabling wireless and text communication in current smartphone when their battery dies.

Is the future for smartphones battery-free?

We believe so. Cellular towers wouldn't require any hardware changes. Networks would have to rely on different protocols and update their back-end software—which they do regularly anyhow.

The phone would also require a chip to provide the functionality of sending communications without battery power. The chip would be a special-purpose IC placed on a piece of silicon.

Then any phone manufacturer that wants to include a “battery-free cellphone mode" could buy and integrate that chip into its design.

How much would the phone cost?

The current prototype isn't being mass-produced, so we don't have a fair indication of the cost. However, when we produce them in large volumes, it has the potential to be extremely affordable, maybe even less than $1 to manufacture. It is very hard to forecast at this early stage.

Have there been any setbacks while building the phone?

Something we found challenging was implementing our own base station using an extensive software-defined radio called Gnu. It cost about $3,500. Software-defined networks decouple hardware from software and execute such software, not necessarily in the equipment but either in the cloud or in clusters of distributed IT servers.

It's not the easiest software to work with. I would say that was the biggest roadblock. Implementing the base station required most of our time.

We struggled because we're essentially taking the smart technology away from the phone and simplifying it—which puts all of the complexity on the base station.

What enhancements do you plan to add?

We want to improve the operating range and audio quality. Additionally, it's only capable of making voice calls—which we'd like to change.

We're working on adding a camera and an E Ink display—a high-visibility and high-contrast display technology with low-power requirements. These technologies would allow the phone to have smartphone capabilities.