LCDs may be the mainstay of consumer displays, but when it comes to picture quality, including high contrast ratio, brighter colors, and wider viewing angles, OLEDs have the edge. These organic light-emitting diode displays are so-called because of their self-emission capabilities, using organic carbon-based compounds and other ingredients to create colors. Because each pixel produces its own light, OLEDs require no backlighting. They are, therefore, more power efficient, and can be fabricated into slimmer and more flexible displays.

Of course, there is a catch. OLED displays are expensive to manufacture, and traditional fabrication techniques need specialized setups. Researchers have been looking at 3D-printing solutions, but even these have had drawbacks, among them a lack of uniformity in the active (emitting) layers of the display.

Recent research from the University of Minnesota (UM) Twin Cities describes a “one-pot” 3D-printing platform for flexible OLEDs that overcomes some of the common printing problems and simplifies the manufacturing process. Essentially, the researchers combined all the critical steps for the production of the display—extrusion printing of the lower layers, spray printing of the active layers, and structural reconfiguration—into a single device, a custom-built tabletop 3D printer.

“Anyone with the basic knowledge of 3D printing can [print] OLED displays...in homes that possess the proper inks and designs.”

—Ruitao Su, MIT

“[Our] printing platform consists of…a high-precision motion-control module, an ink-dispensing module that extrudes or sprays materials, an imaging system that assists the alignment of device layers, and an ink-curing system,” says Ruitao Su, a former Ph.D. student at the university, where he worked on the project. He is now a postdoctoral researcher at MIT’s Computational Design and Fabrication Group.

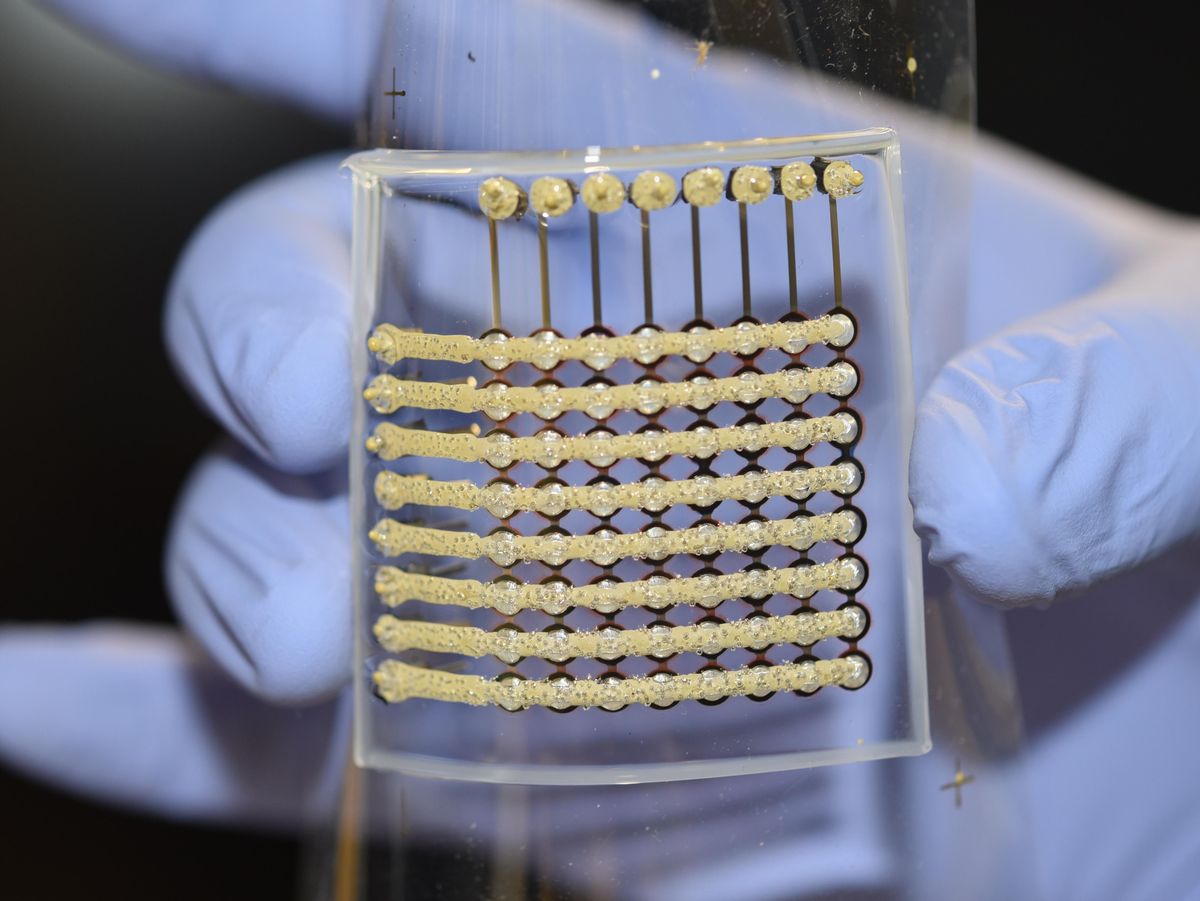

The result was a six-layer, 1.5-inch square flexible display, in which the electrodes, interconnects, insulation, and encapsulation were extrusion-printed, while the active layers were spray-printed using the same 3D printer at room temperature. The device had 64 pixels, each one emitting light. It was also flexible, and the emission remained stable over 2,000 bending cycles.

The major challenge printing the active or emitting layers, Su says, is achieving a relatively uniform morphology on the 3D printer. He says his team at UM solved the problem by generating homogeneous layers of the OLEDs with controllable thickness. Another issue involved creating stable, room-temperature cathode–polymer junctions. That one, Su says, they solved by developing a mechanical compression process “that simulates conventional metal forging but conducted on 3D printers.”

For Su and his team, one of the considerations in coming up with a fabrication process for a flexible, fully 3D-printed OLED display was cost effectiveness. Traditional production processes require expensive microfabrication facilities that have to be housed in clean rooms, he says, but “[in our prototype] the cost…is reduced in terms of the required facilities and specialized personnel.”

Apart from its potential in soft electronics and wearables, this “one-pot” methodology allows for other unique form factors beyond the typical 2D layout. “I envision the direct printing of OLED displays on nonconventional surfaces such as tables, cars, or even human bodies for ubiquitous information display,” says Su.

Such flexible displays could be packaged in an encapsulating material for a wide variety of applications as well. “The pixels can be conformally printed on curved surfaces to integrate with daily objects in the era of Internet of Things…. The OLED pixels can also be printed in 3D matrices so that the entire printed [device] functions as displays.” The group’s print-your-own-display tech could even ultimately enable homemade holograms—though, he says, further innovations in the hardware would be necessary first.

The word “HELLO” was captured while the text scrolled on the 8-by-8 OLED display.Ruitao Su/University of Minnesota

Even though their method was designed for small-batch, customized fabrication, Su says, “The point is that you don’t have to build a semiconducting factory in order to have your desired devices fabricated. Because anyone with the basic knowledge of 3D printing can operate the machine, the OLED displays theoretically can be printed in homes that possess the proper inks and designs.”

Working with flexible OLEDs brings specific challenges too. “[They] require pixels and conductive interconnects that maintain good performance under large mechanical deformations,” Su explains. “Therefore, we selected materials that maintained high electrical conductivities, such as silver-based inks for our electrodes. For the encapsulation, we used a common transparent and flexible polymer, PDMS, to coat the device on top.”

There is plenty of work yet to be done to improve this technology, of course. Better device efficiency and increased brightness are major challenges for 3D-printed semiconducting devices, Su adds, and that is where the next focus of this research will be.

- Nanomaterials Begin to Blur the Lines Between Industrial and ... ›

- Making 3D-Printed Objects Feel - IEEE Spectrum ›

- Print an Arduino-Powered Color Mechanical Television - IEEE Spectrum ›

Payal Dhar (she/they) is a freelance journalist on science, technology, and society. They write about AI, cybersecurity, surveillance, space, online communities, games, and any shiny new technology that catches their eye. You can find and DM Payal on Twitter (@payaldhar).